The Foetus Project by Jorge Lopes Dos Santos

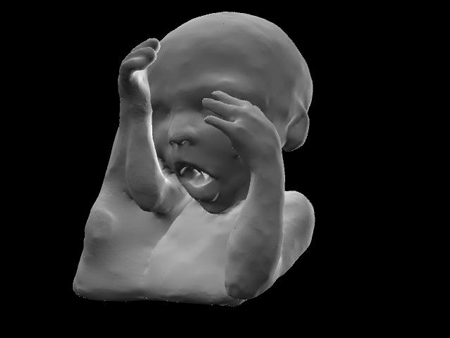

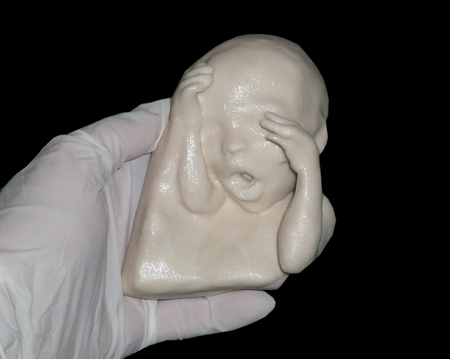

Brazilian design graduate Jorge Lopes Dos Santos has developed a way of making physical models of foetuses using data from ultrasound, CT and MRI scans.

He developed the project in collaboration with a paediatric cardiologist at Imperial College while studying on the Design Products MA course at London's Royal College of Art.

Jorge Lopes Dos Santos hopes the models, which are made using 3D printing techniques, can be used to train doctors and to help with emotional support for parents whose child may be born with deformities.

See all our stories from the RCA show 09 in our special category.

Here's some more information from the RCA, followed by a text from head of Design Products Ron Arad:

--

Medicine is benefiting from cutting-edge research undertaken in the Design Products department at the Royal College of Art.

Research student Jorge Ribeiro Lopes dos Santos has been working with a paediatric cardiologist at Imperial College because he has found a way of using rapid prototyping technology to scan foetuses and produce models as teaching tools for doctors.

“The technology can be also be used as an emotional tool for parents whose foetus might be deformed or need treatment,” said Hilary French, who heads the School of Architecture and Design Products.

Lopes dos Santos, who is sponsored at the college by the Brazilian government, had begun his research in a relatively pedestrian way, looking at how model-making had been used in practical ways over the centuries, French said.

Lopes dos Santos’s work uses the latest computer techniques first exhibited by Ron Arad at an exhibition at the V&A at the turn of the century entitled Not Made By Hand, Not Made in China.

“Something that staff and students are doing is working with cutting-edge technology, digital technology, 3D printing,” French said.

“In the same way that computers have changed design practice, the three dimensional rapid prototype manufacture means you can infinitely customise something.

Ron Arad:

“I don’t know whether I am looking at science or I am looking at art”, commented M.D Heron Werner (physician specializing in Foetal Medicine), an external examiner in his enthusiastic review at Jorge Lopes Dos Santos’s PhD viva.

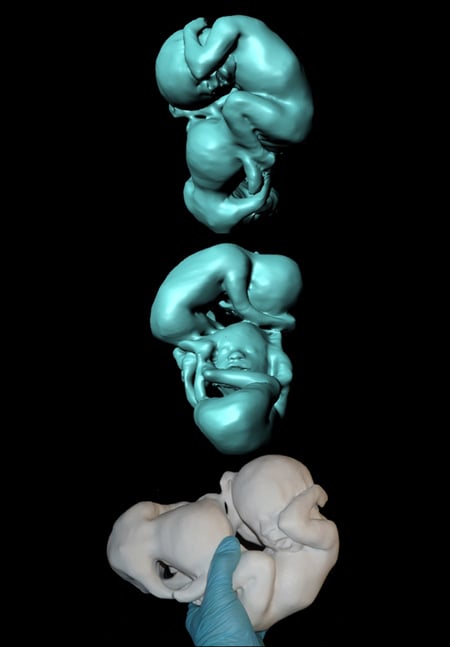

He was referring to a display of 3d printouts, physical models of foetuses in various stages of development, twins in a brotherly embrace, perfect embryos, some with slight deformation, some not yet born, like Jorges own the ’sculptures’ were built from all the various scanning techniques (ultrasound 2D/3D, MRI and CT scanners), in a variety of materials through a number of RP technologies.

The other examiner in the room was Dr. Pablo Bartolo, a world expert on RP (though he has a problem with term rapid prototyping). It was fascinating to watch how the two fought (in the most civilised, academic way) to claim the research to their field.

The medical Dr. had an urgent shopping list for immediate application while the other was pushing for the research to dwell longer in the realm of design and engineering.

It is not difficult to imagine many other camps joining the queue, like campaigners from both sides of the abortion debate, commercial exploiters, fine-art curators etc.

We also want to claim J’s research and his 4 year career at Design Products at the RCA as an example of how we wish to see ourselves in the design products department, an example of a student who came to the RCA with a considerable experience in production techniques, a vast knowledge of modern and contemporary design and an impressive collection of images, information on modelling and prototyping from ancient history to cutting edge digital manufacturing and an open minded, open ended theme for his research, physical models and prototypes and their significance in the advancing design culture.

There was no telling where, in this fast developing field, this research was going to lead, no clues that the documenting and methodical archiving of cardboard models, collecting hand carved foam mock-ups from designers studios, visiting labs of digital manufacturing, were going to lead to this groundbreaking new field of world importance, work so new that still enjoys freedom from being filed exclusively in a single category.

I want to believe that the genuinely pluralist non prescriptive environment of the department, the ambitious atmosphere of curiosity of the 2nd floor studio and the platform’s affinity groups have helped and encouraged the individuals to claim the freedom to create work that is new to them and new to us.

I hope that when we look at the work of this year’s graduates, we will also find yourself wondering whether we are looking at science or looking at art, practical solutions or imagined problems, real proposal or virtual suggestions, introvert indulgence or community spirit - all within Design Products.