3D printing of electronic products could "revolutionise the world around us"

News: engineers at a UK university have printed working electronic devices for the first time using a standard 3D printer fitted with a new type of plastic that conducts electricity.

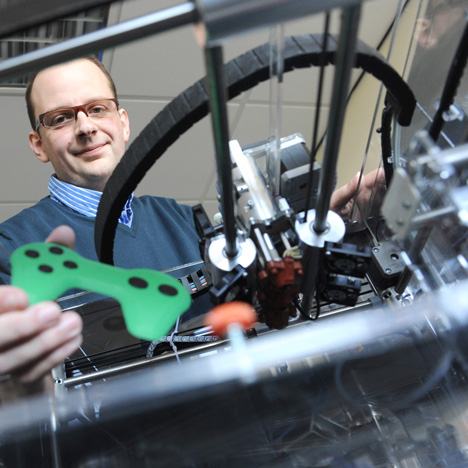

The team used the material, called "Carbomorph", to print a simple computer game controller (top), a glove containing flexible sensors and a mug that knows how full it is.

"This technology could revolutionalise the way we produce the world around us," said Dr Simon Leigh (above), who led the research team at the School of Engineering at the University of Warwick.

Carbomorph is a carbon-rich composite material that can be used in existing 3D printers to print electronic circuits.

Using Carbomorph alongside a regular plastic in multi-headed printers could one day allow the printing of the physical forms plus the electronic innards of objects such as mobile phones and remote controls in one go. Until now, the exterior form and interior workings of electronic devices have had to be manufactured separately.

“It’s always great seeing the complex and intricate models of devices such as mobile phones or television remote controls that can be produced with 3D printing," Leigh said. "But that’s it, they are invariably models that don’t really function."

He added: "We set about trying to find a way in which we could actually print out a functioning electronic device from a 3D printer.”

"It’s a very high-carbon plastic,” said technology journalist Adrian Mars. “That means that with a dual-head printer you can not only print a case for electronics but you can print the buttons, the circuit boards, the tracks, the contacts. And you don’t have to upgrade your printer. If you’ve got a two-headed printer you just buy Carbomorph when it goes on sale.”

Leigh’s research team now plans to work on printing more complex items such as cables that connect devices.

“In the long term, this technology could revolutionalise the way we produce the world around us, making products such as personal electronics a lot more individualised and unique and in the process reducing electronic waste,” said Leigh “Designers could also use it to understand better how people tactilely interact with products by monitoring sensors embedded into objects."

Leigh added: "However, in the short term I can see this technology having a major impact in the educational sector for example, allowing the next generation of young engineers to get hands-on experience of using advanced manufacturing technology to design fairly high-tech devices and products right there in the classroom.”

The full research article, A Simple, Low-Cost Conductive Composite Material for 3D Printing of Electronic Sensors, can be viewed here.

See all our stories about 3D printing.