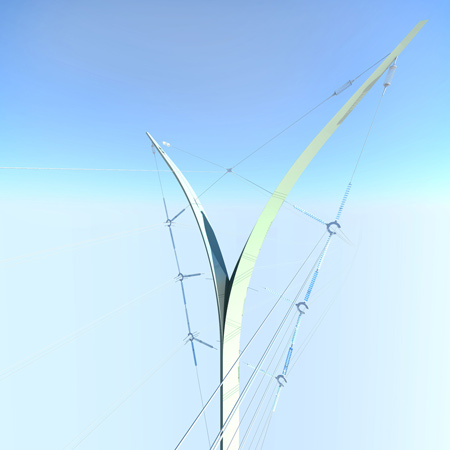

Pylons of the Future Dancing with Nature by Hugh Dutton Associés

Paris studio Hugh Dutton Associés have won a competition to design electricity pylons for Italian energy company Terna.

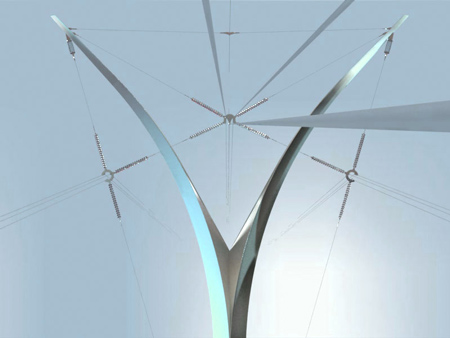

Each pylon would be made of welded sheet steel, individually shaped according to its location and the forces acting on it.

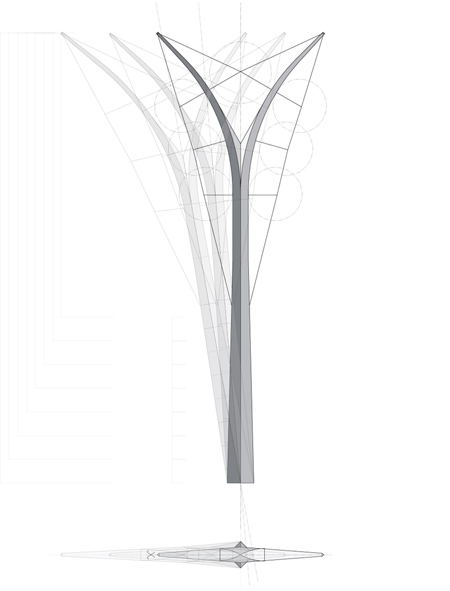

Called Pylons of the Future Dancing with Nature, the design is based on new shoots appearing from the earth.

See also: pylons for Iceland by Arphenotype

Here's some more information from Hugh Dutton Associés:

--

Pylons of the future dancing with nature

French design firm Hugh Dutton Associés (HDA) have won first prize in the "Pylons of the Future" international competition for Italian energy supplier Terna.

The design is based on the conviction that new technologies, both in the design phase and in the construction phase, represent a powerful tool to optimally individualize architectures. This thereby avoids the banality of modernism standardization, whilst limiting material wastage, in a similar process to nature's own selectivity and optimization.

The pylons are inspired by the form of the first tender shoots of a young plant. The first shoots grow out of the ground and are stabilized by a system of tension cables at their tips according to the concepts of Tensegrity as invented by Fuller. Tensegrity itself is a symbiosis of tension and compression. Like a real tree, which is stabilized by the prestress of its bark exerting a tensile force on the heart of the trunk itself that resists this force with a corresponding compressive one. This gives the tree an elastic strength to resist wind forces and retain an optimal elegance.

The very idea of designing an electrical pylon in harmony with nature from the outset seems a fundamental contradiction of principle. Traditional pylons are the very symbol of insensitive intervention of mankind on the landscape. These industrial soldiers that march across the countryside, galvanized steel trellis towers, are certainly optimal and efficient structures, but lack poetry.

For this reason HDA's design for the pylons of the future, like nature's own process, is not guided purely by an intellectual aesthetic. Form and spatial configuration are defined by the forces of nature itself, such as wind, light and temperature, as well as many other parameters of the surroundings, so the pylons respond individually to their natural context and forces, and each one is different from another.

Click for larger image

The path of the cable lines varies as a function of the terrain as it curves around hills and valleys to find a path of least resistance. The pylons lean into the direction of the forces of the cables they are required to carry. Like ourselves, we lean into a strong wind to find our equilibrium. As such the pylons will respond to the terrain they cross and the forces lines that result from them. Rather than dominating the landscape like the industrial soldiers, they express that nature is the stronger force, and not the pylon.

Click for larger image

In the construction phase the pylons are fabricated from flat steel plate cut to individual shapes using contemporary numerically controlled tools, where the shape is automatically transferred to the cutting tool one by one. The flat sheet cut-out shapes are assembled together onto simple jigs and welded using automatic continuous welding machines. As each pylon has a different and optimized form and size, we can avoid excess waste of steel.

Click for larger image

More information about architectural design approaches and the use of complex technologies can be found on HDA's blog complexitys, which is a space for open debate about architecture and complex geometries.

Click for larger image

Client: Terna SpA

Design team: HDA - HUGH DUTTON ASSOCIES, GIORGIO ROSENTAL (team leader), GOZZO IMPIANTI, CEGELEC solutions & Services.

HDA design team: Hugh Dutton, Pierluici Bucci, Pierre Chassagne, Francesco Cingolani, Maria Angela Corsi, Gaetan Kolher, Carla Zaccheddu.