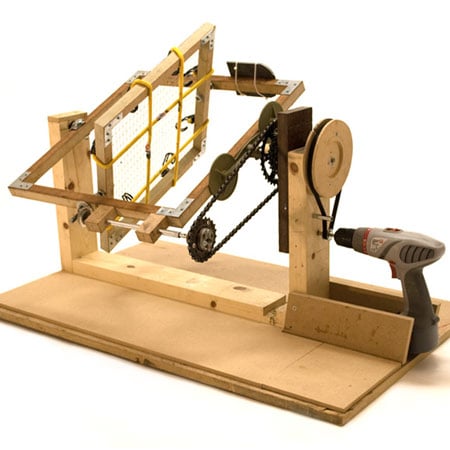

Product design students Andrew Duffy, Craig Tyler and Edward Harrison have built a machine for making plastic objects, which is powered by a cordless drill.

Made of scrap materials, the device produces hollow, plastic products by rotating a mould on two axis while resins harden inside.

The three young designers developed the apparatus to help them learn about industrial, rotational moulding while studying at the University for the Creative Arts in the UK.

Watch a movie about the project here.

Here's some more information from the designers:

--

To have an idea is one thing, to fully understand the process is paramount to good design.

Whilst Studying on a BA honours degree, Product Design students Andrew Duffy, Craig Tyler and Edward Harrison wanted to learn more about a manufacturing process named rotational moulding. It was decided that the best way to learn about this process was to construct a miniature machine.

The D.I.Y rotation moulding machine was built to replicate the industrial process to help further understand its possibilities. The machine was built at no cost from scrap materials and simply powered by a cordless drill. With the use of cold setting bio resins, Andrew and Craig are now able to create a fully sustainable range of hollow plastic products.

The Real Rotational Moulding process is an exceptionally flexible and cost effective method for creating thermoplastic products and components. The rotational moulding process is a high-temperature, low-pressure plastic-forming process that uses heat and biaxial rotation to produce hollow, one-piece parts. Rotational moulds are significantly cheaper than other types of mould. Very little material is wasted using this process, and excess material can often be re-used, making it a very economically and environmentally viable manufacturing process.