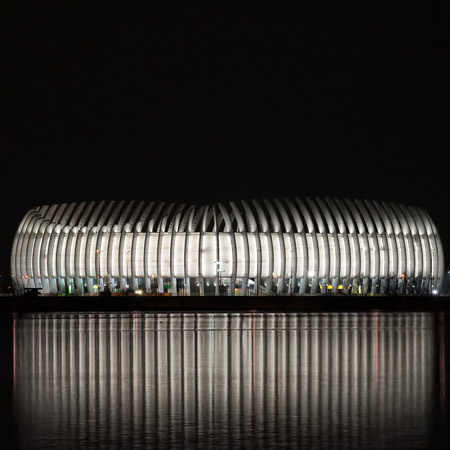

Arena Zagreb in Croatia by architects UPI-2M was awarded Structural Design of the Year at the World Architecture Festival in Barcelona last week.

The muitifuntional hall comprises a polycarbonate facade and steel roof, both suspended from 86 curved reinforced-concrete columns.

The building has a footprint of 9,0340 square metres and columns vary in height between 26.5 metres and 38.8 metres.

More winners from WAF:

Havaianas by Isay Weinfeld

Corian Super-Surfaces Showroom by Amanda Levete Architects

Mapungubwe Interpretation Centre by Peter Rich Architects

Category winners

Here's some more information from the festival:

--

Arena Zagreb is multifunctional indoor hall with the footprint of 90340 sq. m. It is located in the southwestern part of Zagreb, Croatia, at one of the main city entrances. Also it lies opposite of popular Zagreb recreation and sports center Jarun. Arena Zagreb became a new city emblem in one of its main axes, offering to the citizens a large palette of amusement events. The unique shape of this building is strongly inspired by its significance in the city context, but also by its mega-structural characteristics that predefine main bearing elements. The shell shape is following the structure logic – it partly covers the inner space with curved columns. Basic shape and structural element of this hall are prestressed prefabricated reinforced concrete curved columns with the height up to 39 m. Eighty-six large curved prestressed, pre-fabricated concrete columns are carrying the main façade, mutually connected by illuminant semi-translucent polycarbonate envelope that enables for various light effects. They also support stands and carry suspended steel roof structure. Columns’ height goes from 26,5m to 38,8m. Span of steel roof structure equals 104m.

The major parts of the hall are: suspended steel roof structure, pre-stressed, prefabricated, reinforced concrete columns, and monolithic reinforced concrete structure of the stands, pit and entrance plateau.

Under the stands and field of play there is a garage with surface of approximately 30 000 m2 (with capacity of 817 vehicles). The garage lies on joint-less foundation slab with work dilatations. Number of work dilatations depends on available concrete fabrication plant (up to1000m3 per day). Part of work dilatations is performed in a way that one stripe (with width of 1 m) is being left in the middle and concreted subsequently. Such concept ensures undisturbed process of creep and shrinkage in initial faze. Avoiding of dilatation provides more simple (with easier quality control) and faster hydro-insulation montage in conditions of relatively high underground water. Above the garage there is 5 floor monolithic reinforced concrete structure of arena. Statically, it represents spatial frame with beams (span up to 10 m) and columns. On height of +5,0 (point of main pedestrian entrances) there is a support for 86 reinforced concrete prefabricated columns. After monolithisation of columns on mentioned height as well as on contact with beams of upper floors, they make one unit with monolithic structure. Reinforced concrete structure is made out of concrete of quality C30/37.

Statics scheme (cantilever with length up to 15m), load (2000 kN on the top of cantilevered beam), shape (curved), cross section (oval), size (39 x 8,5m) weight (up to 220 t) - all these data are the reason of using the mentioned technology in production of columns.

Columns are being produced on the site, using the concrete C50/60, in horizontal position inside the specially designed formwork and partly prestressed, in order to provide the fastest possible extracting from the formwork (30% of force). After extraction out of formwork, columns are being put in a „stand“, 12 cables are fully pre-stressed (1200 kN per cable) and injected. At that moment, columns are ready for „verticalisation“ and transfer (using crane with capacity of 500 t – at the end of the arm outstretched 70 m, one will have necessary capacity) till planned location for embedding.

Columns are embedded on pre-built anchors (HALFEN, part of anchors on which column is stacked is embedded in column’s bottom) and temporarily stabilised (till monolithisation process is finished). Monolithisation with spatial frame structure of the hall will provide necessary horizontal stability of columns in high seismic conditions (calculated acceleration of the ground 0, 27 g). On the top of the column, there is a point for anchoring of cables predicted, which carry roof structure.

On full locked cable with diameter of 66 mm, calculated resistance of 2636 kN and range of 103, 7 m using vertical and diagonal hangers (full rod with diameter of 34 mm), roof structure is suspended. Suspended steel roof structure is made out of steel HEB 450 profiles in major and secondary direction. Wind influence is dominant with uplift action on the roof with (wo= 0,7kN / sq.m; additional safety factor 1,5; shape factor c=-0,62). The weight of structure and stabilization truss have favourable influence on dynamics of structure, provides load disposal in case of asymmetric combination and ensure cable replacement.

In order to fulfil main characteristic of the ARENA ZAGREB – multi-functionality, it is necessary to predict locations where the equipment (sound speakers, spot lights etc) will be installed (hanged). For this Arena, total weight of such equipment equals 100 t. Deflection of structure for design loading (which includes elastic deformation of hanging points on top of the column) equals 33 cm. Steel beams of major direction (their ends) are supported by elastomeric bearings embedded in stands structure. Elasticity of bearings provides for roof structure to „float“above the hall (uplift is blocked).

CategoryStructural Design - Spans (eg bridges, stadiums, big sheds)

LocationZagreb, Croatia

ArchitectUPI-2M