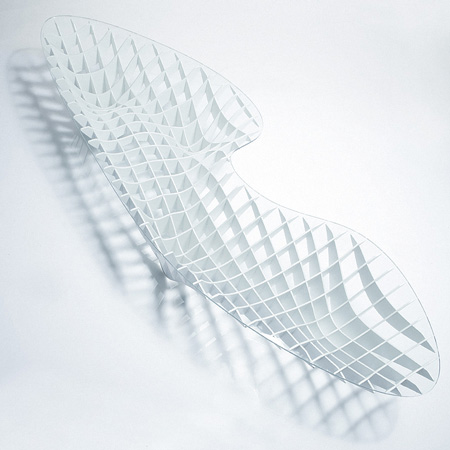

Chilean digital design and fabrication studio GT2P have designed a table made of intersecting two-dimensional forms that are designed using parametric software.

The Sectionimal table is part of a series of "parametric furniture" created using a program called SECTION.

The software can adapt the parameters of the table in response to the material selection and the associated characteristics, optimising the design for digital fabrication.

Photos are by Bside Studio.

Here are more details from GT2P:

--

The Sectionimal

The sectionimal table is part of a series of parametric furniture generated by an algorithmic program of links (fitting) called SECTION, designed by the Chilean studio GT2P.

What distinguishes the SECTION Program is its capacity to construct complex volumes by means of two-dimensional links. In order to achieve this, the program uses generative modulators such as grasshopper (KAD or KCAD), in which algorithms that efficiently integrate design and digital fabrication are developed.

A relevant characteristic of the modulators is its ability to enable a designed program to adapt the table parameters, its shape, xyz dimensions, material density, number of sections, tolerances according to materials and endings that conform to the user’s specific requirements.

The table is available in plywood, corian and aluminium with tempered glass overlay. Size, L180cm W70cm H35cm.

About us:

GT2P arises from the compatibility of interests that we discovered among us. This has to do with productive aspects of architecture, design and the ability to generate it from digital media. Our studio develops processes that go beyond the representative, covering the areas of fabrication, manufacturing and construction from these media.

Therefore, our main interest is the design process supported by knowledge (KAD,Kknowledge Aided Design). We generate, process, and communicate this knowledge by means of digital instruments. Among other things, we consider in our work spatial syntax, environmental control and the constructive components of production. This allows us to perceive the critical necessities of a given project and tackle them using the specific knowledge previously collected.

Thus, parametric design turns out to be the most efficient tool to solve a problem in an integral manner (i.e. definition of the problem, solution and implementation).

In furniture, for instance, we have produced each of our products according to an specific rule. Following this automatized process, we can build an entirely different piece of furniture by just modifying a few variables within the rule. In this way, we may achieve one of our main goals: massive customization.

For us, it is of the greatest relevance the relationship with our suppliers (software developers, material providers, etc.) and the acquisition of an in-depth acquaintance with their work. For it is in the perfect knowledge of the production conditions and its variables that we may innovate in the construction of our unique products.

GT2P studio enriches its labor working in close collaboration with other professionals in the field, dealers, retailers, and investors who believe in innovation.