Earn/Urn by Neil Conley

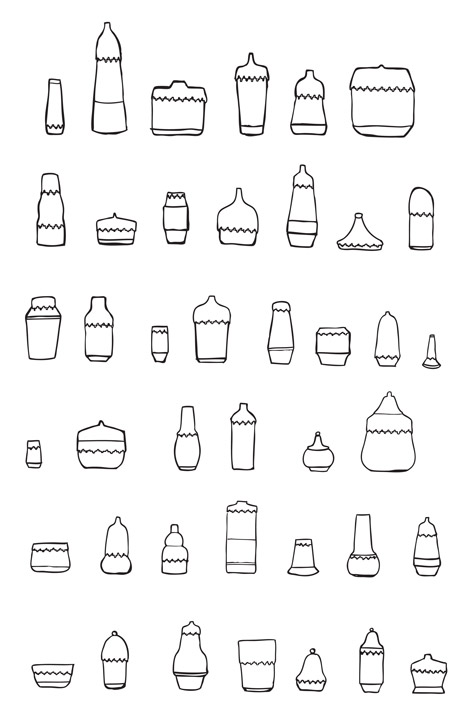

Design graduate Neil Conley has made a series of funerary urns from reclaimed carbon fibre.

Called Earn/Urn, the products are part of a project finding uses for carbon fibre extracted from decommissioned aircraft through new incineration processes.

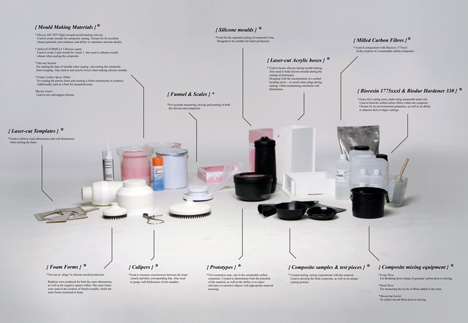

Conley combined the reclaimed fibres with a plant-based resin and cast the resulting material in a process similar to slip-casting.

Click above for larger image

He hopes the material could be applied in industries that use carbon fibre for status rather than technical requirements, helping to use up some of the redundant material found in scrapyards where carbon fibre components have outlived the rest of a machine.

Conley completed the project while studying at Northumbria University and presented the work at New Designers in London earlier this month.

Here's some more information from the designer:

Earn / Urn is first and foremost a by product of the Xendless project.

The aim of the project was to develop a sustainable carbon fibre composite, as well as a manufacturing process that made it suitable for the design of fine products.

Carbon fibre is, by all intents and purposes, a manufacturing marvel. For applications that require a superior strength to weight ratio, it is unmatched by any single polymer or metal. The fibres themselves too possess other useful characteristics, for example, the ability to resist radiation and static, and the capacity to carry an electric current. It is for these reasons that carbon fibre has become the staple material of Aerospace, as well as many other hi-tech industries.

However in recent decades, the association of carbon fibre with the ‘pinnacle of performance’ has lead to it transcending from the functional uses of hi-tech industries, to uses of exclusivity and edition in industries such as lifestyle.

This was one of the key triggers for the Xendless project. Despite Carbon fibre possessing many incredible properties, one that it does not possess is the ability to bio-degrade. For this exact reason, thousands of tonnes of composite products lie dormant in dumping grounds around the world – many trapped within objects that cannot match up to the lifespan of the material itself. Combine this with the growing use of the composite in new aircraft, and you cannot help but question the choices of designers in lifestyle industries to use it.

New advances in composite recycling do however provide a solution, or at least the beginnings of one. New pyrolosis methods now make it possible to unlock these ‘wonder fibres’ from composites, leaving fibres ‘as pure as the virgin material’, prime for re-use.

It is these fibres that are used within the Xendless composite. However, instead of relying on petrochemical resins, the fibres are bound with a renewably sourced ‘bio-resin’, made using plant oils rather than crude oil. It is hoped that this composite may display an alternative and appropriate way for the previously ‘irrelevant industries’ to use the material. Not only could this prevent the addition of composites to the dumping grounds, but it may actually help to reduce them.

Whilst we cannot help that many industries rely on carbon fibre, there will always be a need to find a home for their waste.

The process developed within the Xendless project is one that is unique to the material - and equally environmentally friendly. The composite is processed using a slip-casting method similar to that of ceramics. However, unlike ceramics, the ability to remove the composite in a flexible state before tempering (to reach optimum rigidity) eradicates unsightly blemishes such as split lines from moulds.

The choice to use the process for a series of cremation urns was one of design poetics; a carbon cycle for the wider carbon cycle. The products are intended to demonstrate not only the potential of the individual material, but also how relevant material sourcing can re-inject relevance to objects of narrative and poetry.

See also:

.

|

|

|

| Carbon fibre chair by Studio Geenen |

Carbon fibre lamps by Delphine Frey |

Carbon fibre stool by Mile |