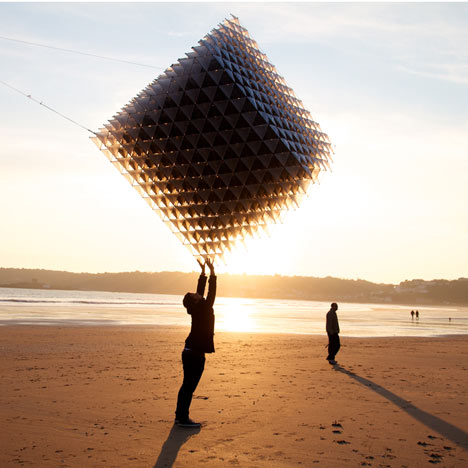

This deceptively hefty-looking cube is actually designed to fly like a kite.

Made from over 23,000 individual components, the Little Shining Man kite comprises carbon-fibre rods, a hand-made composite fabric normally used for yacht sails and specially designed, rapid-prototyped nylon connectors.

Three of the structures will hang in the atrium of a development by client Dandara in Jersey and be taken down once a year to fly in the local bay.

Artists Heather and Ivan Morison created the sculptures in collaboration with London architectural designer Sash Reading and Birmingham fabrication design studio Queen and Crawford.

Heather and Ivan Morison are best known for pavilions and outdoor installations, including the Black Cloud shelter made of scorched timber that we featured in 2009.

Photography is by Matt Porteous.

Here's some more information:

The design of the structure is based around the tetra kites of Alexander Graham Bell. A double wing module has been duplicated and arranged into a tight cellular structural arrangement that appears as a heavy, un-flyable cubic mass. Utilising lightweight materials and the symmetry of the module and composition, it is able to fly freely and steadily.

Click above for larger image

The kite flown in the images is one section of an arrangement of three, that come together to create the final piece. It will be hung as an installation for Dandara’s new Castle Quay development in St. Helier, Jersey, where it will be permanently displayed in the atrium as a piece of sculpture - a sculpture that is intended to fly. Once a year it will be taken down from its spot in the building and flown in St. Aubin’s Bay.

Click above for larger image

There were several challenges in realising Little Shining Man. The structure had to be as strong and light as possible in order to fly, but had to return to earth with minimal damage so it could be installed as a piece of sculpture. Carbon fibre rod and Cuben fibre - a hand made composite fabric used primarily in Racing Yacht Sails, achieved the perfect combination of strength and weight. The visual impact of the fabric produces an etherial sense of depth and refraction that gives the heavy mass the lightest touch.

Click above for larger image

Queen & Crawford designed a joint system, the CKJ_01, a universal Nylon joint that would handle every connection in the composition. We work closely with 3TRPD in Newbury who are at the cutting edge of the Rapid Prototyping Industry. Printing the joints allows us to quickly design, produce, test and refine in a short time frame. The material is light and strong, perfect for this application.

More than 23,000 individual components make up the complete structure. Entirely assembled by hand, from design through to delivery more than 16 months of work.

Conceived: Ivan Morison

Design/technical consultation: Sash Reading

Component design, structure detail design, fabrication: Queen + Crawford

Design documentation + visualization: Emily Thurlow

Fitting manufacture: 3TRPD