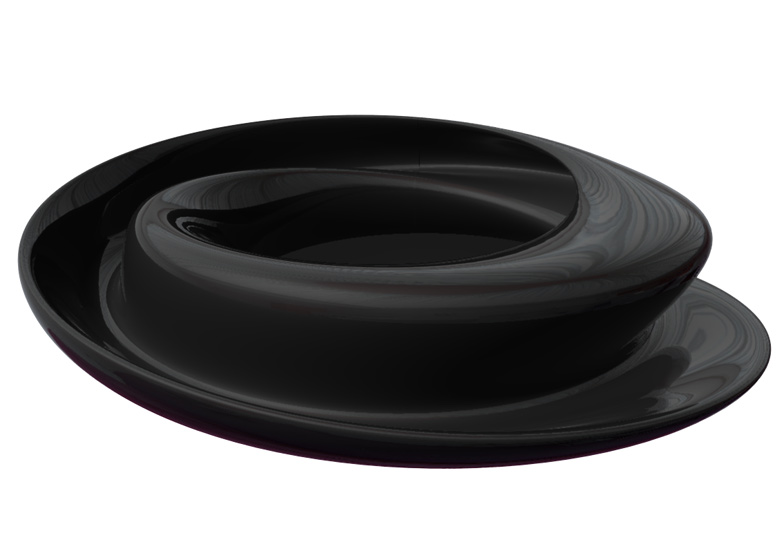

London Design Festival: Curator, author and furniture designer Suzanne Trocmé has created a 3D-printed ceramic bowl and egg cup based on the continuous form of a Möbius strip.

The pieces were made with Staffordshire ceramics company 1882 Ltd using ceramic powders in a process that combined 3D printing with traditional firing methods.

1882 Ltd. was formed last year by Emily Johnson to continue her family's ceramics legacy. The company is named after the year in which the Johnsons first began producing ceramics at Stoke on Trent Potteries.

The collection was launched at an exhibition hosted by 1882 Ltd during the London Design Festival until yesterday, alongside Plates by Emily Johnson and Crockery by Max Lamb.

See all our stories about ceramics »

Here's some more information from the designer:

Bone China: New works by Max Lamb, Suzanne Trocmé & Emily Johnson

London Design Festival 2012

In 1882 the Johnson Brothers began producing ceramics in the heart of the Stoke-on-Trent Potteries. 130 years later, 1882 Ltd continues the Johnson legacy with the launch of two collections of fine bone china: Crockery by Max Lamb and Plates by Emily Johnson. Joining them is Suzanne Trocmé with her inaugural collection, Aspirals.

Aspirals is based upon the möbius, a continuous form which is not unfamiliar but usually exists sculpturally rather than as a functioning object because it is almost impossible to manipulate it into a useful form.

The bowl and egg cup have been made in 3D printed ceramic, a sintering process that has its own challenges in ceramic powder. The Aspirals have been experimental for three years, when Trocmé first worked with the möbius form and tried to design a form that could have a base but still retain the illusion of the continuum. At first she tried to make the form using lost wax out of metals, but the process proved too difficult because there always had to be a way to hold on to the piece in manufacture.

When putting together British Bone last year with Emily Johnson, Trocmé decided to see if the forms could be made somehow in ceramic. The pieces are fired at 1200 degrees, so produced in a combination of ways - rapid prototyping and traditional firing methods.

Currently in bone white and a soft black, the black resembles a finish Trocmé used to produce many years ago with pieces I made at the wheel in pot, and then burnished with a spoon and fired in an underground home made peat kiln.