Researchers at MIT plan to 3D print a pavilion by imitating the way a silkworm builds its cocoon.

The research team, headed by architect and Mediated Matter Group founder Neri Oxman, attached tiny magnets to the heads of silkworms to discover how they “print” their pupal casings around themselves.

“We've managed to motion-track the silkworm’s movement as it is building its cocoon,” said Oxman. “Our aim was to translate the motion-capture data into a 3D printer connected to a robotic arm in order to study the biological structure in larger scales.”

The pavilion is part of a research project to explore ways of overcoming the existing limitations of additive manufacturing at architectural scales and follows recent proposals for a house made of 3D printed concrete sections and a dwelling made of prefabricated plastic elements.

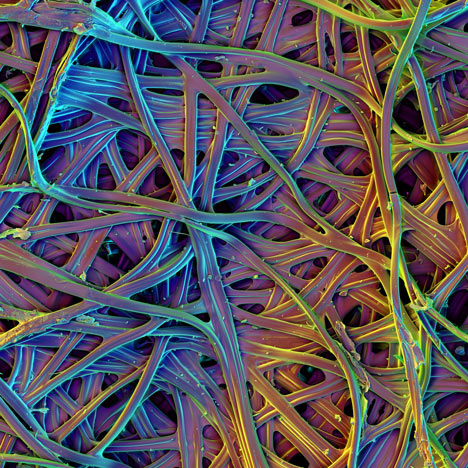

Top image: colour scanning electron microscope image of the exterior surface of a silk moth cocoon. Image by Dr. James C. Weaver, Wyss Institute, Harvard University

Today's 3D printers are mostly able to produce homogeneous materials with the same properties throughout, whereas natural materials often exhibit varying properties, or "gradients". A silk worm, for example, is able to produce a cocoon with a tough exterior and soft interior by varying the density and pattern of the silk fibres it deposits.

"The worm rotates its head in 8-figure movements so as to allow for the distribution of silk, its density, its thickness and through these manipulations it controls its mechanical properties based on structural and environmental constraints,” says Oxman. “For instance, the inner layers of the cocoon are relatively soft while the outer layers of the cocoon are stiffer. The silkworm than varies the properties of silk according to function and can be considered the biological equivalent of a mobile 3D multi-material printer."

The Silk Pavilion will be built using digital fabrication technologies at MIT’s Media Lab. It will be installed on 22 April and will measure around 12 feet by 12 feet.

Oxman believes that freeform printing using robotic arms has more potential for architecture than existing 3D printing systems, which use gantries that can only move in three directions and which require complex support structures to be printed at the same time to prevent the building components collapsing under their own weight.

“In traditional 3D printing the gantry-size poses an obvious limitation; it is defined by three axes and typically requires the use of support material, both of which are limiting for the designer who wishes to print in larger scales and achieve structural and material complexity” explains Oxman. “Once we place a 3D printing head on a robotic arm, we free up these limitations almost instantly."

In the future, buildings may be constructed by swarms of tiny robots, she says. “I would argue that 3D printing is more than anything an approach for organizing material. When considered in this way it is possible to move beyond the technology and its current limitations into larger scale constructions with geometrical and material complexity.”

Oxman believes material limitations can be overcome by printing with responsive materials (which she calls “4D printing”); gantry limitations can be overcome by printing using multiple interactive robot-printers (“swarm construction”); and process limitations can be overcome by moving from layering to weaving in 3D space using a robotic arm (she calls this “CNC weaving”).

Oxman believes that in the immediate future 3D printing in construction scales can only be successful if it is to challenge traditional construction techniques while being sensitive to cultural contexts.

She adds: “Transcending the scale limitation by using larger gantries can only offer so much; but if we consider swarm construction or rebar-integrated printing we are truly pushing building construction into the 21st century”. Mediated Matter group research assistant Steven Keating is investigating these possibilities.

The CNSilk Pavilion is being developed by the Mediated Matter group at the MIT Media Lab in collaboration with Professor Fiorenzo Omenetto at TUFTS University and Dr. James Weaver at the WYSS Institute at Harvard University.

Researchers at the Mediated Matter Group developing this work include Markus Kayser, Jared Laucks, Carlos David Gonzalez Uribe, Jorge Duro-Royo and Michal Firstenberg (Mediated Matter, MIT Media Lab).

Note: a version of this story was first published on 6 March. It has been edited and updated following feedback from MIT.