Royal College of Art graduate David Steiner has turned his house into a factory by adapting household appliances to create a range of tableware and lighting (+ slideshow).

"The project began as an experiment in self-sufficiency, to some extent a reaction against the growing prevalence of desktop digital manufacture," said David Steiner, adding that he wanted to show what can be achieved using his existing possessions.

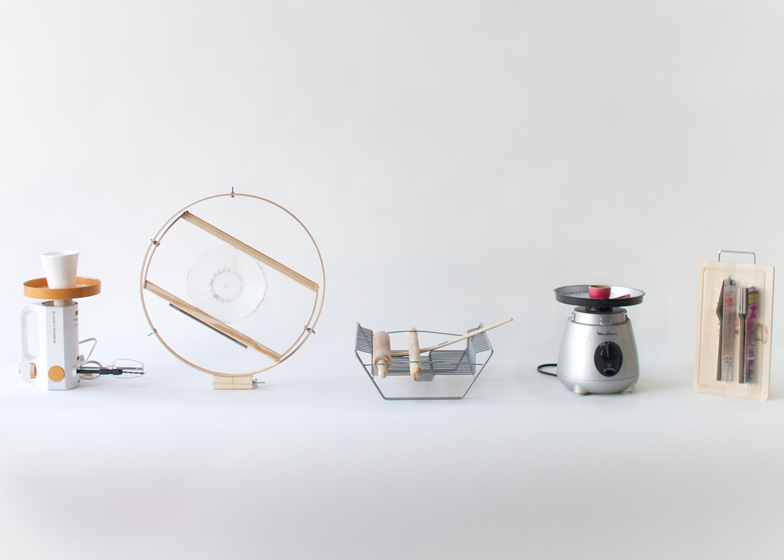

Simple interventions transformed everyday objects that can be found in most homes into tools that replicate industrial manufacturing processes, such as rotational moulding and steam bending.

A lampshade made from a baking tray was cut with scissors before being pressed into shape in the edge of a door frame.

An embroidery hoop and sections of a notice board frame were used to make a framework for a polypropylene mould that was put in a washing machine to create a device for rotation casting tableware.

Cutlery was cast from pewter in a mould made from a cereal box cut into shape and fixed to a chopping board.

Cork from notice boards was layered and turned on a lathe surface attached to the top of a blender.

A mixer was transformed into a pottery wheel used to throw a cup made from sugar paste.

Wooden rulers dunked in water were heated in a microwave and bent to form a tray in a process replicating steam bending.

Other graduation projects presented at Show RCA 2013 included a range of copper, maple and glass tools for making cosmetics at home, bicycle helmets made from paper pulp and a bioplastic made from crab shells.

See all our stories from Show RCA 2013 »

See more homeware »

Photography is by Lynton Pepper.

This movie shows how the machines were made and the products were manufactured: