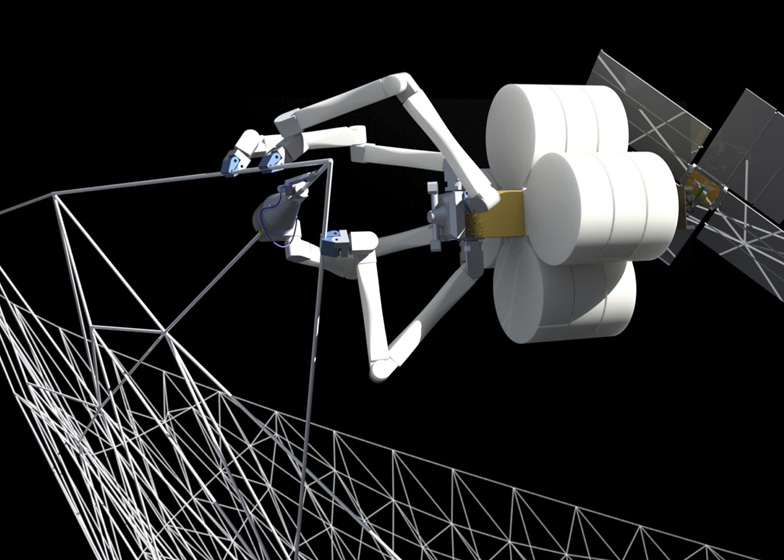

News: NASA is developing an orbiting factory that will use 3D printing and robots to fabricate giant structures such as antennas and solar arrays of up to a kilometre in length, as part of its ongoing search for extra-terrestrial life.

The US space agency this week announced it was awarding technology firm Tethers Unlimited Inc (TUI) a $500,000 contract to develop the facility.

The NASA funding - a second-phase contract that follows an initial contract issued earlier this year - will allow TUI to continue work on its SpiderFab technology, which allows large-scale spacecraft components to be built in space, avoiding the expense of building the components on earth and transporting them into space using rockets.

“On-orbit fabrication allows the material for these critical components to be launched in a very compact and durable form, such as spools of fiber or blocks of polymer, so they can fit into a smaller, less expensive launch vehicle.” Said TUI CEO and chief scientist Dr Rob Hoyt. “Once on-orbit, the SpiderFab robotic fabrication systems will process the material to create extremely large structures that are optimized for the space environment.

Currently spacecraft components are designed to be built on the ground and folded up to fit inside a rocket shroud. The process is complicated, expensive and limited by the availability and size of existing rockets.

Hoyt added: "This radically different approach to building space systems will enable us to create antennas and arrays that are tens-to-hundreds of times larger than are possible now, providing higher power, higher bandwidth, higher resolution, and higher sensitivity for a wide range of space missions.”

The technology would allow NASA to use far smaller rockets to deliver components to the orbiting factory, which could be used to manufacture trusses to hold solar arrays and solar sails, antennas and masts of almost unlimited size. TUI's website suggests that kilometre-long trusses or football-field sized sails could be produced.

Space factories would also significantly reduce the risk involved in launching delicate equipment on rockets, where the chance of failure is high. Instead, relatively inexpensive raw materials would be launched into orbit.

TUI will now develop a “Trusselator” capable of using additive manufacturing technologies such as 3D printing to fabricate truss structures in space. TUI's website describes the Trusselator as a system "for on-orbit fabrication and integration of solar arrays using a combination of 3D printing and automated composite layup techniques".

“The Trusselator is the key first step in implementing the SpiderFab architecture," said Hoyt. “Once we’ve demonstrated that it works, we will be well on our way towards creating football-field sized antennas and telescopes to help search for Earth-like exoplanets and evidence of extraterrestrial life.”

The announcement is the latest in a string of projects exploring how additive manufacturing could be used in space. Last month NASA certified the first 3D printer for use on space stations, while at the start of the year architects Foster + Partners revealed that it was working on techniques to print habitable structures on the moon.

Via GigaOm.

Here's a press release from TUI:

Spacecraft that Build Themselves… in Space! – Tethers Unlimited Wins NIAC Phase II Contract to Develop “Self-Fabricating” Spacecraft

Bothell, WA, 29 August 2013 – NASA announced today that the NASA Innovative Advanced Concepts (NIAC) program has selected Tethers Unlimited, Inc. (TUI) for award of a $500,000 Phase II contract to continue development of its “SpiderFab™ technologies for in-space fabrication of spacecraft components.

The SpiderFab architecture adapts additive manufacturing techniques such as 3D printing and robotic assembly technologies to enable space systems to fabricate and integrate large components such as antennas, solar arrays, sensor masts, and shrouds on-orbit. Currently, large spacecraft components are built on the ground, and are designed to fold up to fit within a rocket shroud and then deploy on orbit.

This approach is very expensive, and the size of these components is limited by the volume of available shrouds. “On-orbit fabrication allows the material for these critical components to be launched in a very compact and durable form, such as spools of fiber or blocks of polymer, so they can fit into a smaller, less expensive launch vehicle.” Said Dr. Rob Hoyt, TUI’s CEO and Chief Scientist. “Once on-orbit, the SpiderFab robotic fabrication systems will process the material to create extremely large structures that are optimized for the space environment. This radically different approach to building space systems will enable us to create antennas and arrays that are tens-to-hundreds of times larger than are possible now, providing higher power, higher bandwidth, higher resolution, and higher sensitivity for a wide range of space missions.”

In the Phase II effort, TUI will develop and demonstrate methods to enable additive manufacturing of high-performance support structures and integration of functional elements such as reflectors and antennas. In parallel with the NIAC effort, TUI is working under a NASA Small Business Innovation Research (SBIR) contract to develop a “Trusselator” device that will fabricate truss structures to enable in-space construction of large solar arrays.

“The Trusselator is the key first step in implementing the SpiderFab architecture, said Dr. Hoyt. “Once we’ve demonstrated that it works, we will be well on our way towards creating football-field sized antennas and telescopes to help search for Earth-like exoplanets and evidence of extraterrestrial life.”

About Tethers Unlimited, Inc.

Tethers Unlimited, Inc. develops innovative technologies to enable transformative capabilities and dramatic cost savings for missions in Space, Sea, Earth, and Air. Its technology portfolio includes advanced space propulsion systems, high-performance radios for small satellites, and methods for additive manufacturing of multifunctional spacecraft structures. To learn more about TUI and its products, please visit www.tethers.com.