Ami Drach and Dov Ganchrow recreate Stone Age tools with 3D-printed handles

Designers Ami Drach and Dov Ganchrow have created a range of 3D-printed handles to give the ancient multipurpose hand-axe a series of specific functions (+ slideshow).

The hand-axe is a prehistoric teardrop-shaped stone tool that was intentionally chipped from both sides into a symmetrical form. It is likely to have been used as a "one size fits all" tool for a variety of purposes including skinning animals, preparing food and as a dagger for over 1.4 million years across Europe, Asia, Africa and North America.

For their Man Made series, Dov Ganchrow and the late Ami Drach sourced flints from an Israeli desert to recreate the early implement.

"The first stage of the project was one of hastened evolution and bleeding," said Ganchrow. "Flint rocks of desirable size, shape and material quality were sourced from the Negev desert in southern Israel, while time was spent improving and understanding the skill of knapping - striking the flint with a softer stone to create controlled breakages, and chipping away flint flakes as the impact's shock wave runs through the stone. Needless to say this is where the bleeding came in..."

Once shaped, the flint pieces were 3D-scanned so the handles could be designed to fit perfectly.

"The flint hand-axes were three-dimensionally scanned with the gracious help of Dr Leore Grosman's digital lab at the Hebrew University, Jerusalem's institute of Archaeology," Ganchrow continued. "The digital hand-axe files then had handles custom-designed exemplifying various tool uses."

By adding 3D-printed handles each designed only for a specific task, all other options for use were removed – transforming a general tool into very specialised one.

The team created nine handles, named from two to ten due to the numbering system used for archaeology lab's original scans.

Number 2 uses cord to attach the stone into split piece of wood like a wedge, forming a spear. Number 3 is a clip-on holster for carrying the stone so it can be thrown in defence.

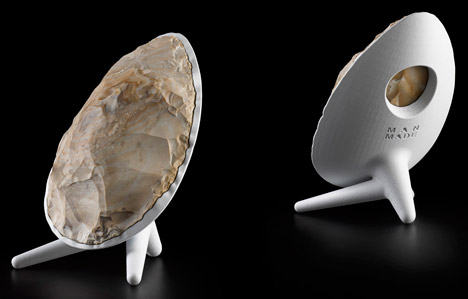

Number 4 has interchangeable heads, while Number 5 allows the stone to be used for cutting and slicing. Number 6 is a tripod display case that presents the stone-axe as a courtship object.

A platform above the handgrip in Number 7 enables the stone-axe to be used for indirect percussion, an action similar to hitting a chisel with a hammer and transferring the force to a stone.

Number 8 has a two-handed grasp for digging or pounding and Number 9 is designed for left-handed use.

Finally, stone hand-axe handle Number 10 resembles a tool probably used for woodworking in a chopping-pulling motion.

"The handles were printed in Verogray – a performance polymer with support from Stratasys," Ganchrow said. "The parts were prepared and assembled on the original flint hand-axes, effectively joining the two most temporally distant Making technologies: flint knapping and 3D printing."

Bezalel Academy of Arts and Design graduates Ami Drach and Dov Ganchrow established their design studio in 1996.

Photography is by Moti Fishbain.

Design: Ami Drach and Dov Ganchrow

3D-scanning: Dr Leore Grosman and the Institute of Archaeology at the Hebrew University, Jerusalem.

3D-printing: Stratasys/Objet