Lumps of lava act as built-in dimmer switches for porcelain lamps by GT2P

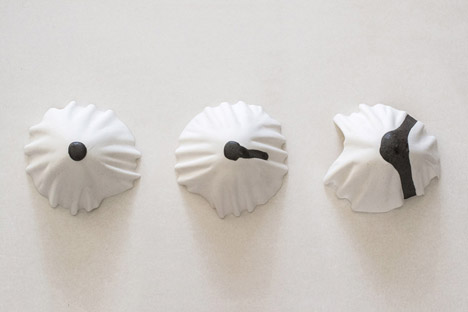

These porcelain lamps by Chilean studio Great Things to People (GT2P) are turned on and off by stroking blobs of lava in their centres.

The mound of cooled stone in the middle of each of GT2P's Porcelain vs Lava Lights acts like a dimmer switch.

The studio has been experimenting with pieces of cooled lava from Chile's Chaiten and Villarrica volcanos, combining the dark material with contrasting light porcelain.

Swiping a finger over the smoothed chunks of lava alters an electrostatic field created by a capacitive sensor. This change in the field prompts a small electronic device, or microcontroller, to turn the light on and off.

"The microcontroller can be programmed many times as you want with different functions or scenes giving us the possibility to create interactive installations as well," Guillermo Parada of GT2P told Dezeen.

The sensor is attached to a brass element embedded into the lava, which also anchors the lamp to the wall.

The amount of heat needed to melt the lightweight, porous black stone to a workable viscosity coincided with the baking temperature of ceramic used to form the shades.

"After these findings we asked ourselves what would occur if we put together a porcelain biscuit and lava into the oven," they explained.

"We supposed that porcelain would remain solid at that temperature and lava would turn viscous. The result was that lava drains slowly over solid piece of porcelain, where the shape, gravity and temperature permit – almost like a candy."

"Thanks to the slow cooling process, the lava contracts gradually without breaking the porcelain but holds it completely, achieving a collaborative material with zones of greater mechanical resistance within the piece," they added.

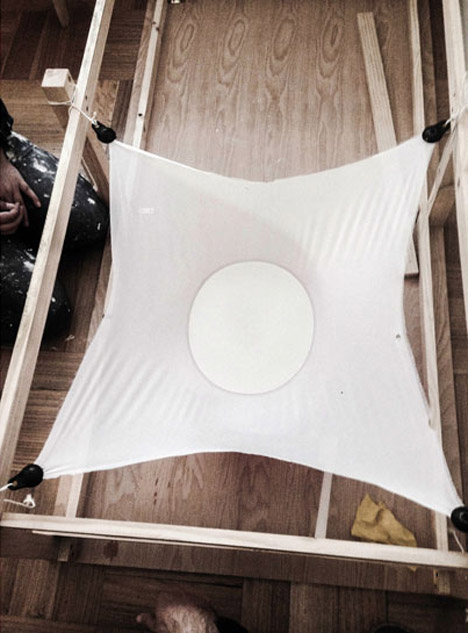

The porcelain shades were shaped on an updated version of the studio's Catenary Pottery Printer (CPP), which uses a suspended cloth and gravity to generate objects with an analogue form of parametric design – more about how it works in our previous story.

During the casting of the shades, layers of ceramic were added to change the thickness, and therefore the opacity, of the finished pieces.

"This last method generates a perfect fit for the development of luminaries made by CPP system, that allow us to generate very slim and reinforced pieces, establishing a contrast between opacity in the hanging points and translucency over the edges where the light comes through," the studio said.

The lava was placed on top of the porcelain and then baked, reinforcing the structures where it melted. An LED bulb is attached to the back of the strengthened section to illuminate the surface from behind and give a soft glow around the edges.

"These lights include an anchor point for each porcelain piece, so it was necessary to strengthen the area," said the studio. "The incorporation of a different material has to be made in order to reinforce the hanging zone and keep the translucency of the porcelain without augmenting the thickness of the piece."

"Also, it was needed to generate a shadow or contrast that would integrate the anchor point to the visual expression of the piece," they added.

The early prototypes they created form the Wall Mounted Luminaires and Mockup Chandelier lighting collections, which were displayed as part of the Open House exhibition hosted at the offices of design website L'ArcoBaleno during New York design week last month.

A few designers have been experimenting with lava. Formafantasma used cooled lava from Mount Etna in Sicily to create a collection of furniture, which they described when we visited their Eindhoven studio, and Kieren Jones devised a concept to cast sections of buildings using molten lava from erupting volcanoes.

Photography is by Cristobal Cañas and GT2P.