3D weaving can "reduce cost and improve structural integrity" in architecture

Dezeen and MINI Frontiers: RCA graduate Oluwaseyi Sosanya shows us the 3D-weaving machine he invented, which he claims could be used to create better sportswear, medical implants and even architecture.

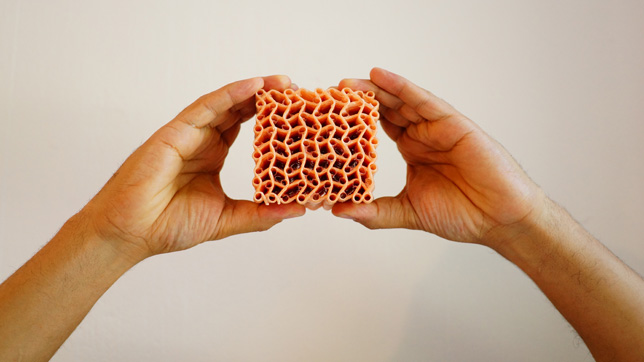

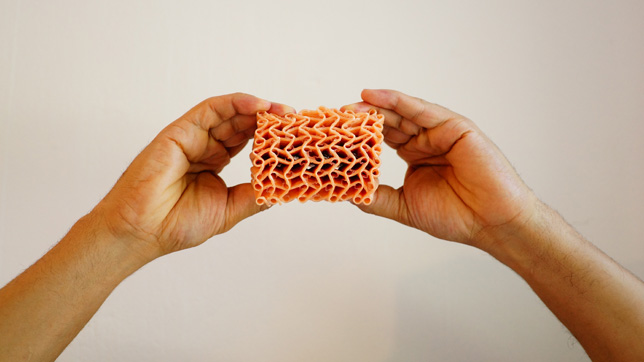

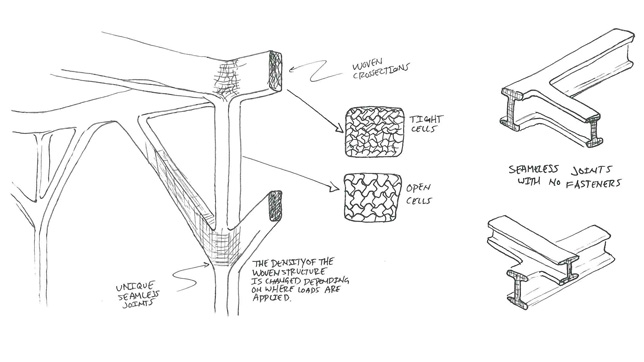

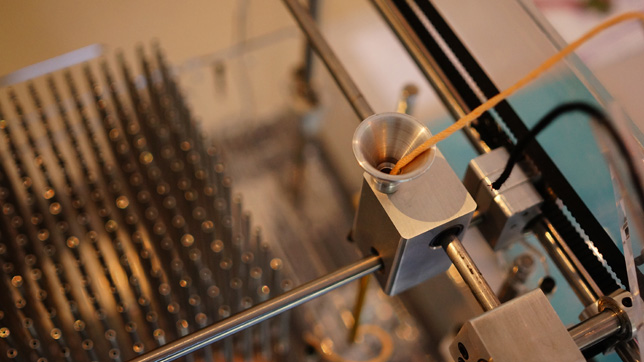

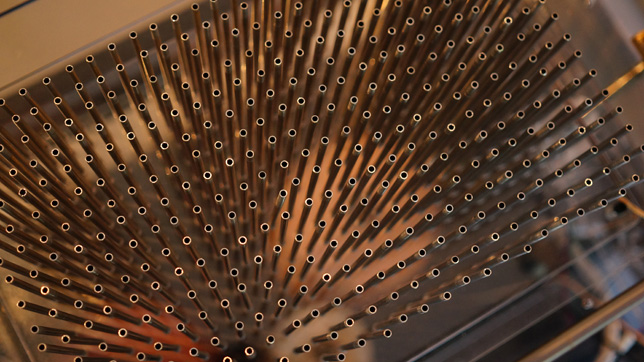

Sosanya's machine, which he developed as part of the Royal College of Art's Innovation Design Engineering course, uses adapted CNC-milling technology to weave complex 3D structures with varying densities.

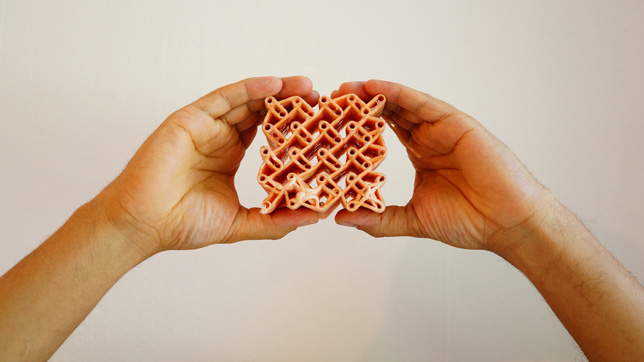

"There are structures that are extremely rigid and structures that can be completely soft," Sosanya explains. "In architecture we can look at custom panels for insulation and custom extrusions, varying the properties throughout the piece as it's woven."

"At one extreme you [might] have a lot of load on a beam and the other extreme less load, so you want less material. You can [weave] a lightweight structure with a continuous process. Anything where you can reduce the number of joints but maintain structural integrity is an advantage. It's a benefit. So it's reduction in cost but also [better] structural integrity."

The machine works by feeding thread through a nozzle that weaves around warp posts in X, Y and Z coordinates. A silicone resin is extruded at the same time for added structural stability.

However, at its current scale, Sosanya's machine is better-suited to creating shock-absorbing sportswear than buildings.

Dezeen Book of Interviews: our new book, featuring conversations with 45 leading figures in architecture and design, is on sale now

"For the show I wanted to show something that people can readily identify the material with at its present scale and for that I designed a pair of shoes," Sosanya says. "It's just a single thread that weaves the sole all the way into the three-dimensional shape that it is and then it's laminated to the bottom of the upper."

He continues: "But there are other applications for this. Let's say I'm making a kneepad. Towards the upper thigh I would definitely want a lighter more flexible structure but right on the kneecap itself you'd want something that can withstand a lot of impact."

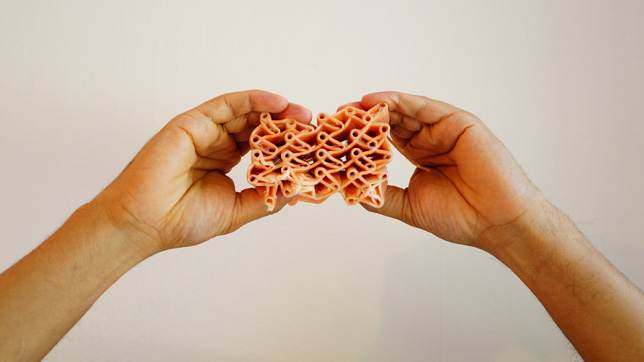

At the other end of the scale, Sosanya says there is interest in the technology from the medical industry.

"Medical textiles are really taking off right now," he says. "If [you use] natural fibres, natural resins, it can be really interesting. There are things like heart-stints, implants, non-invasive surgery, where you need to put something soft and malleable that can expand inside the body. With this process you can crush the structure, slide it into the body and then it expands."

He continues: "I have been talking to some bioengineers at Brunel [University]. Moving forward I would like to team up with an industry leader in this area and take the project to another level."

Dezeen and MINI Frontiers is a year-long collaboration with MINI exploring how design and technology are coming together to shape the future.

Footage of the 3D Weaver in action used in this movie is courtesy of Zuzanna Weiss.

The music featured in the movie is a track called October by UK Producer Jo Noon. You can listen to the full track on Dezeen Music Project.