"Technology adds an incredible advantage to fashion design"

Fashion and technology: in the first part of a series focusing on designers who are introducing the fashion world to new technologies, Dezeen speaks to architect Julia Koerner about how advances in 3D scanning, modelling and printing are creating a "revolution in customised fashion pieces within ready to wear" (+ interview + slideshow).

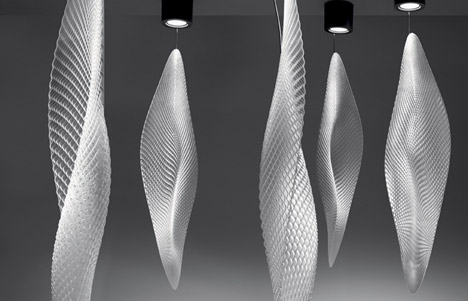

3D-printed garments have become a common sight on the Haute Couture catwalks of designers like Dutch fashion designer Iris van Herpen.

Austrian architect Julia Koerner, who collaborated with Van Herpen on these digitally fabricated garments, is now working on transferring the technology used to create the elaborate garments into everyday clothing production as part of what she calls an "exciting moment in fashion design".

"Body scanning and 3D-modelling techniques allow you to design towards a perfect fit, and through minimal changes in the code I can create variations of adaptations in the design," she told Dezeen. "This automated process is a revolution in customised fashion pieces within ready to wear."

Koerner believes that developments in the properties of materials that can be fabricated on a 3D printer, including greater flexibility and density variation, are enabling more practical clothing to be produced – taking digital manufacturing out of the world of Haute Couture and making it more accessible.

"Now that materials inherit textile performance, I believe the technology adds an incredible advantage to fashion design," said Koerner. "It is now possible to custom fabricate a garment which fits perfectly without refitting."

Koerner, a lecturer at American architect Greg Lynn's Suprastudio at UCLA, utilises computer modelling software from the architecture industry to create 3D fashion designs that can be tweaked and adjusted for custom fit, which she believes could revolutionise the way we buy clothes.

"This means, if you have a 3D file of the fashion garment, only a few changes need to be made in the algorithm and the pattern, size, design of the whole piece changes in a few seconds," explained Koerner.

"This parametric design process derives from architectural design and allows for custom mass fabrication, which will have a big influence on online shopping and the whole fashion industry."

Encouraging cross-disciplinary work at the "convergence of fashion design, architecture and industrial design" is necessary to maintain standards and continue to push boundaries, according to Koerner.

Van Herpen, whose collaborators include architect Daniel Widrig, MIT professor Neri Oxman and Koerner herself, has paved the way for the fashion industry to accept and experiment with digital manufacturing through her Haute Couture collections – Hybrid Holism, Voltage, Wilderness Embodied and most recently Bio Piracy.

"Especially within Haute Couture, additive manufacturing had its break through because Iris collaborates with architects who bring this technology into her discipline," said Koerner.

But further experimentation with materials is needed before printed textiles become the clothes on our backs.

"Currently I am focussing on integrating flexible material within fashion design," said Koerner. "I find the new material Polyjet Flex interesting as it inherits different densities and stiffnesses within the same material. Computationally you can control which areas of a surface should be more rigid and which areas should be more flexible."

Koerner is continuing to work with Van Herpen to integrate these new materials into her fashion designs, with the latest collection due to debut at the designer's Paris fashion show this week.

Read the full interview with Julia Koerner below:

Dan Howarth: What has the fashion industry gained from digital technology so far?

Julia Koerner: Additive manufacturing sets no limits in geometry and complexity of three-dimensional design. During the past few years, material science within additive manufacturing technology has advanced. I also had the opportunity to explore a new flexible material called TPU 92A-1 with [3D-printing company] Materialise and [Dutch fashion designer] Iris van Herpen. Now that materials inherit textile performance, I believe the technology adds an incredible advantage to fashion design. Especially in ready to wear, as it is now possible to custom fabricate a garment which fits perfectly without refitting. Body scanning and 3D-modelling techniques allow to design towards a perfect fit and through minimal changes in the code I can create variations of adaptations in the design. This automated process is a revolution in customised fashion pieces within ready to wear.

Dan Howarth: What new materials and processes have already been successfully integrated into fashion?

Julia Koerner: For the Hybrid Holism 3D-printed dress [designed with Van Herpen] in 2012 we used a technology called stereolithography. The raw material revealed a honey coloured semi-translucent texture.

"The geometry is built slice by slice from bottom to top in a vessel of liquid polymer that hardens when struck by a laser beam. For Materialise, it all started in 1990 with the RP technology stereolithography. Stereolithography is now one of the most widely used rapid prototyping techniques for plastic models and still the core process at the Materialise rapid prototyping shop."

For the Voltage and Biopiracy 3D-printed dresses we used a material named as TPU 92A-1 and the 3D-printing process is called laser sintering. This is a powder based printing technique and allows for flexibility in the material, which performs almost like a textile material. The Voltage dress was the first fashion piece ever printed with flexible material in 2013.

Dan Howarth: What are the most important digital technologies currently used in fashion?

Julia Koerner: The parametric modelling softwares that allow you to design complex mathematical scripted algorithms, as well as polygon modelling softwares that allow for organic designs. These digital technologies are extremely beneficial for digital fabrication processes such as additive manufacturing.

Dan Howarth: Which technologies have you used in your own work and why?

Julia Koerner: My expertise covers most digital fabrication techniques deployed in current design processes. I work within an inter-disciplinary approach that sets myself apart from other individuals within the industry, my work is at the convergence of fashion design, architecture, and industrial design – realised by innovative and intelligent use of additive manufacturing (3D printing) and robotics. My work has been featured at the Venice Biennale, Paris Haute Couture, and institutions such as the FRAC and Art Institute of Chicago to name a few. Within these digital technologies I explore cutting edge digital techniques and software tools within the digital crafting design processes.

Dan Howarth: How can current technologies be developed to improve their suitability for fashion?

Julia Koerner: Once the material science advances and we will be able to print in textile fibres, and once materials will have textile identical performance, then I believe the technology will add an incredible advantage to fashion design.

Dan Howarth: How will digital technology benefit the fashion industry in the near future?

Julia Koerner: One big question I ask myself all the time: who is curating the quality of digital fashion design? As of today, it is for sure the experts in using 3D software and experience of 3D-printing processes. Once this knowledge is coupled with structural performance in a garment together with traditional fashion expertise there is potential for quality!

Dan Howarth: How will emerging technologies help clothes and accessories to become more/better integrated with the body?

Julia Koerner: Digitally crafted fashion pieces can be custom fit as well as custom changed per individual. This means, if you have a 3D file of the fashion garment, only a few changes need to be made in the algorithm and the pattern, size, design of the whole piece changes in a few seconds. This parametric design process derives from architectural design and allows for custom mass fabrication, which will have a big influence on online shopping and the whole fashion industry.

Dan Howarth: What developments are you currently working on that bridge technology and fashion?

Julia Koerner: Currently I am focussing on integrating flexible material within fashion design. I find the new material Polyjet Flex interesting as it inherits different densities and stiffnesses within the same material. Computationally you can control which areas of a surface should be more rigid and which areas should be more flexible. Further I am investigating how the same structural behaviour can be achieved by variations within geometry.

Dan Howarth: Who else is pioneering the changes in fashion and technology?

Julia Koerner: Especially I would like to mention Iris van Herpen, youngest Haute Couture member and dutch fashion designer, who I've collaborated with over the past few years. I find it brilliant that she is collaborating with young architects from across disciplines, who are so outstanding exploring the digital boundaries within fashion design.

I am inspired by the work of my colleagues Daniel Widrig and Neri Oxman, who both have an architectural background as well and also collaborated with Iris previously. In order to generate complex digital three-dimensional geometries, one not only needs to be an incredible 3D modeller but also you need to have an understanding of structural integrity, which is really important throughout this complex digital design process. It is the combination of mathematic algorithms, logic in material behaviour and aesthetic which allows us to create these intricate 3D structures.

Dan Howarth: Do you think the fashion industry has accepted technology yet?

Julia Koerner: Yes I think that especially within Haute Couture additive manufacturing had its break through, because Iris collaborates with architects who bring this technology into her discipline. It is an amazing feeling to have the opportunity to be part of this exciting moment in fashion design and I am looking forward to where it will develop towards in the near future.