Cauliflowers create moulds for "monster" stool by Studio Pasternak

The legs of this stool covered in a skin-tight coating of black rubber were formed using silicone moulds cast from raw cauliflowers (+ slideshow).

Berlin-based Studio Pasternak made the Dematerialise stool as part of a research project.

The aim was to generate an object that would create "dissociation through dematerialisation of familiar forms and structures," according to the studio.

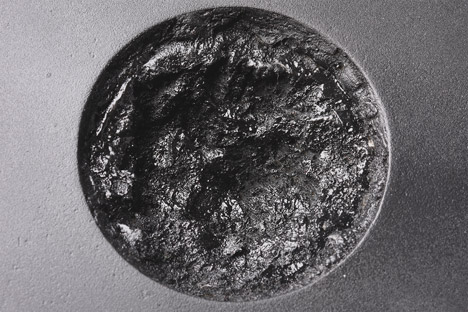

The result is three knobbly black legs formed out of cauliflower shapes with ends tipped in brass. These support a round flat surface that features three "craters" where the legs meet the seat.

The unusual leg shapes were developed following a series of experiments to make forms that are hard to replicate using computers, creating moulds from vegetables, fungi and "viruses".

The seat was made using a "digital-subtractive process" – cutting wood using a computer numerically controlled (CNC) cutting machine – to offer a contrast in techniques.

"To generate perfect circles with a computer is easy. But if you start to create naturally grown, organic forms, algorithms are rather hindering," said studio founder Marcel Pasternak.

"Even if you try to mix in irregularities by hand the rational mind stands in the way. It permanently tries to create regular patterns," he explained. "This is why we engaged ourselves in funguses, roots and various viruses. At the end we created a monster from cauliflower."

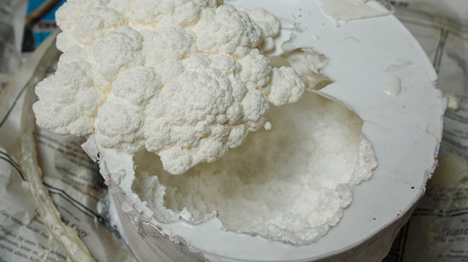

Silicone was poured over raw cauliflowers and left to set, creating a series of moulds for casting small PU-resin pieces. These were then stuck together and cast in more silicone to make the final leg mould.

"We chose cauliflower because it has the perfect balance between regular and irregular structures," Pasternak told Dezeen.

"When you have a closer look at the cauliflower you will detect the same spiral-pattern in each bigger segment. But each segment seems to have random volume. It seemed perfect for building our favored organic-uncontrolled-growth association."

To ensure each leg was set at the right angle, the mould was attached to a model of the seat cut out of MDF wood using a CNC machine.

The resin poured into the moulds expanded while it hardened, creating an extra rise at the top. This additional material was used to attach the pieces to the three holes in the seat, with the surface left raw to generate a rough finish in the "craters" at the top of each leg.

"Our research projects thematise unconventional handling of traditional manufacturing techniques like moulding, casting or sculpturing," said Pasternak. "For this we often use materials and structures found in nature because they emphasise the handcrafted unique appearance or are even essential for this new technique."

The final piece was then coated with a skin of black rubber and the rounded ends of the legs were given brass covers to protect them from knocks and scratches. Studio Pasternak has produced the stool in a limited edition of 20 pieces.

Other designers who have experimented with casting vegetables to create objects include Viennese duo Mischer'Traxler, who made a series of bowls using ceramic powder packed around raw turnips, cauliflowers and peppers.