A biologist and a designer are developing a bacteria and yeast "micro-factory" that could one day enable consumers to grow their own products at home (+ slideshow).

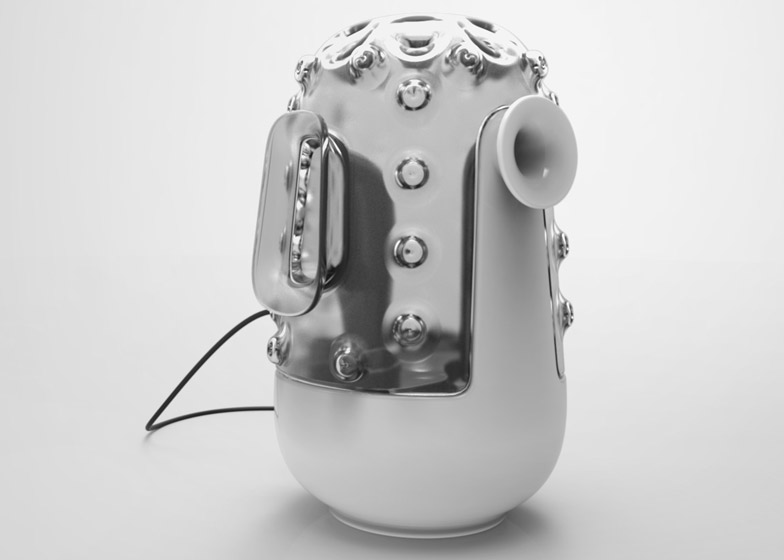

Biologist Aakriti Jain and industrial designer Guillian Graves combined their skills to develop Growduce – a machine that would turn cellulose into everyday consumer products.

"We have imagined a future where small micro-factories will be the go-to machines to create everyday consumer products," said the designers.

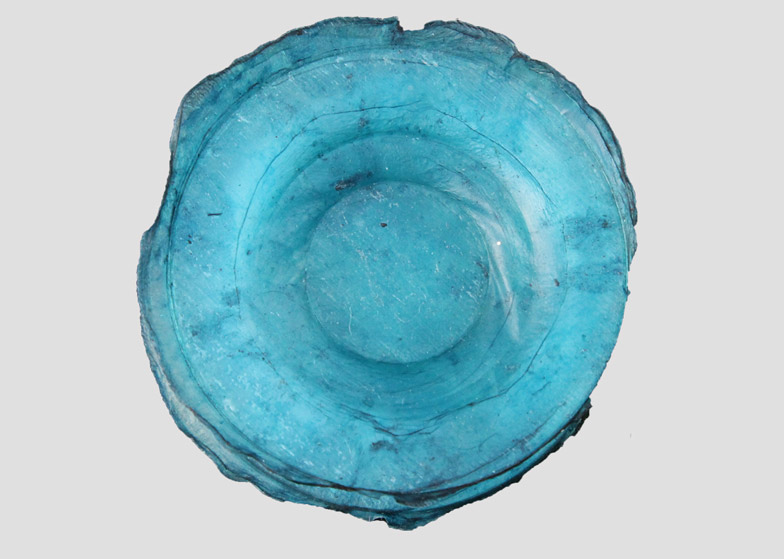

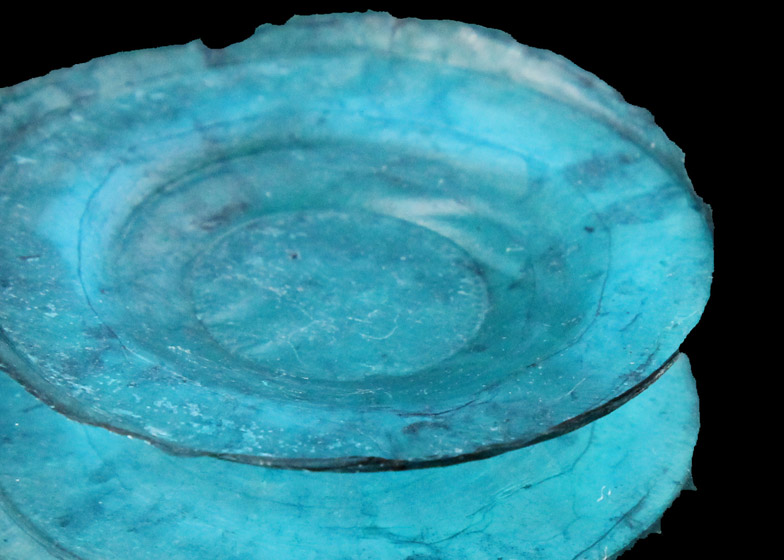

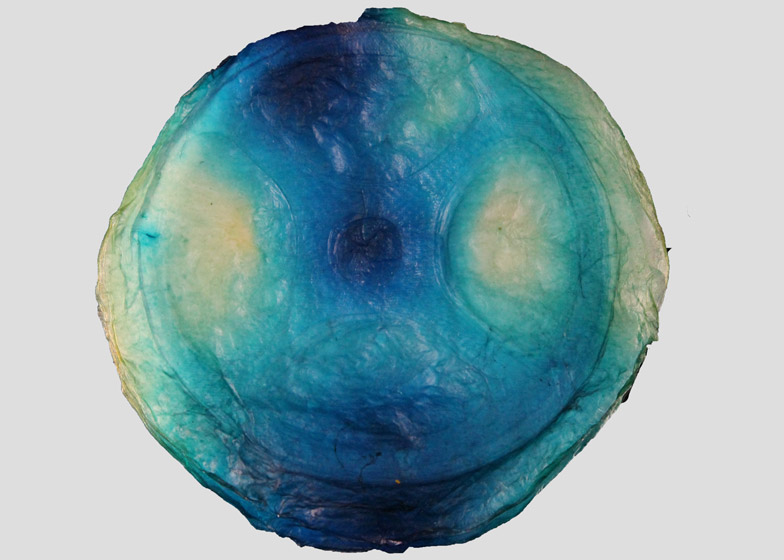

Still at a conceptual stage, Growduce relies on colonies of bacteria that can produce layers of cellulose – a type of naturally occurring polymer material formed from molecules of glucose – in relatively short periods of time.

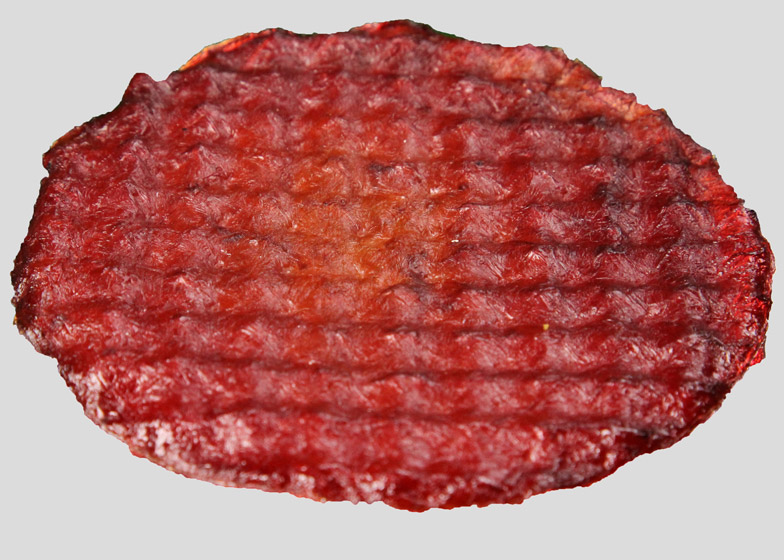

By moulding the flexible cellulose as it grows, it can be formed into different useful items. When most bacteria-grown cellulose sets it becomes takes on properties similar to leather.

Jain and Graves hope that the self-creation of products using this process will eventually eliminate the need for the packaging and transportation of goods, which increase their cost and harm the environment.

"In today's linear design process, though individual items seem inexpensive at first, they actually come at a great, undisclosed cost," the duo said.

"From layers of plastic packaging, immense transportation costs of the various chemicals and materials that go into creating ordinary products, then transporting the products from the producer to the supplier and finally to your home, the energy consumed by the production machines, the waste production and disposal processes, and more all sum to an enormous hidden environmental cost," they added.

The designers hope to complete their first Growduce products – bandages for minor scrapes or burns – by the end of this year, and have plans to make gloves and other clothing and accessories after that.

The Growduce micro-factory contains a symbiotic colony of bacteria and yeast (SCOBY) that grows on compost material and requires very little maintenance.

The cover enables the addition of additives, such as mint, aloe vera and natural pigments, and features holes to allow the cultures to breathe.

Inside, moulds give varying shapes and textures to the growing cellulose created by the bacteria. The intention is that the moulds will be open-sourced, enabling people to share designs for the things they want to make.

"As a proof of concept, I conducted a host of simple experiments with bacterial cellulose to demonstrate the different shapes, textures, colours, and additives we can play with," said Jain. "The experiments are not close to being comprehensive, but demonstrate the potential for such a product."

A pH and temperature monitor connected to a mobile device enables people to check the health of their culture.

"The idea is that it will be a small device that lives in every home just as any other kitchen or bathroom appliance, and that it will be as easy to use as a coffee-machine," said Jain.

The only materials that would be needed to use Growduce are waste and compost, and the created products are organic and recyclable, resulting in what the designers describe as a "circular design strategy".

"Growduce embodies a thought process, a direction of technological development that works with the intricacies of biology to diverge from the teachings of the industrial revolution," the designers said. "It gives the power and the tools to the consumer to grow truly environmentally symbiotic products."