AERO designs wooden bicycle frame to explore techniques for architecture

Milan 2015: bike manufacturer AERO created this prototype bicycle frame from layers of birch to test wooden structural techniques that can be applied to architectural projects (+ slideshow).

The bicycle was conceived by Martino Hutz, Atanas Zhelev and Mariya Korolova whilst working on a wooden structural design for a London house, during their studies at the University of Applied Arts Vienna.

"We received lots of interest from structural consultants following the design of the house," explained project manager Atanas Zhelev. "To further develop our ideas and the technology for large-scale buildings, we chose to start at a smaller scale by creating a bicycle."

"The bicycle is perfect to test how wooden structures work in different scales with different loads," he told Dezeen.

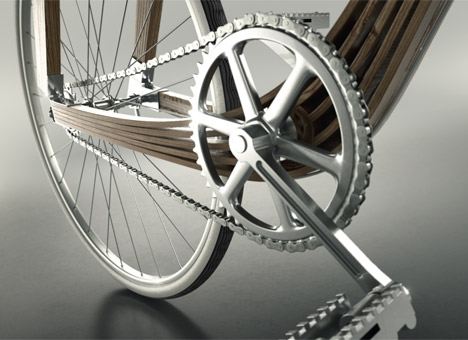

Lamellas – very thin layers of wood – form the frame, splaying at the points where the crank and peddles are fixed as well as below the seat. This design replaces conventional spring-based suspension systems, providing structural lightness, improved flexibility and greater strength, according to Zhelev.

"We are trying to find the best structural solution for this particular suspension system so that it doesn't flex too much," continued Zhelev. "It needs to provide a comfortable ride whilst being capable of absorbing big shocks."

According to project designer Martino Hutz, the bicycle combines structural functionality and aesthetic clarity. He describes it as a hybrid of Le Corbusier's mantra "form follows function" and the Oscar Niemeyer quote "form follows beauty".

Each length of birch wood was cut into 0.9-millimetre sheets, which were then glued together to form the final shape. The natural fibres of each wooden element were aligned to enhance overall strength as well as increase rigidity.

"The choice of wood as the material for this project is especially significant," added Zhelev, "as it not only combines natural beauty and resource friendliness, but also offers the elemental properties of being flexible."

The layering principle was also an important aspect to the wooden prototype, which the team believe is a better way of creating wooden shapes than milling timber blocks.

"This usually wastes a lot of wooden material and destroys the natural structure of the wood," said Zhelev.

"The project seeks to go beyond the conventional bicycle through the investigation and establishment of new manufacturing methods using wood-based materials for larger constructions," he concluded.

The team have since investigated introducing layers of carbon fibre or aluminium within the wooden lamellas, which the designers say will increase overall structural strength with less material.

"The carbon absorbs the sheer force, which is higher on both sides of the wooden block, while the birch offers flexibility," explained project engineer Mariya Korolova. "The ratio between the carbon and the birch would control the overall flexibility of the wooden lamellas."

The final prototype is scheduled to be manufactured this year and will be subject to a test for long-term stress build-up to prove its viability and longevity.

The prototype was first shown at Milan design week 2015 as part of a presentation by Ezgaat Architects.

Project credits:

Design: AERO

Management and technology development: Digital Architects – Mariya Korolova, Atanas Zhelev

Concept and design: Martino Hutz Architecture – Martino Hutz

Partners: Studio Zaha Hadid, Institute of Architecture, University of Applied Arts Vienna

Structural consultant: Altair Engineering

Manufacturing and materials: Höller

Media production: Maveo Schneider & Kreitmeir