Graduate shows 2015: Royal College of Art graduate Shih-Yen Lo has created a set of tools that allow inexperienced users to make precise and complex cuts in sheet materials like cardboard, foam, leather and cloth (+ slideshow).

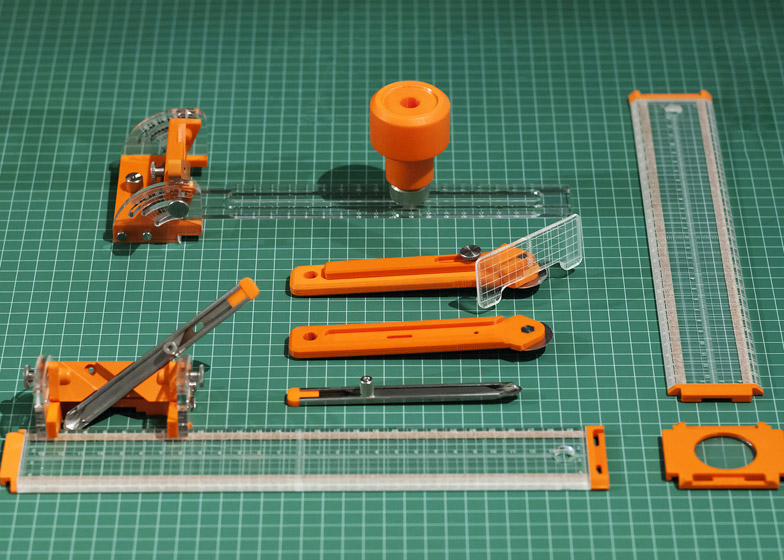

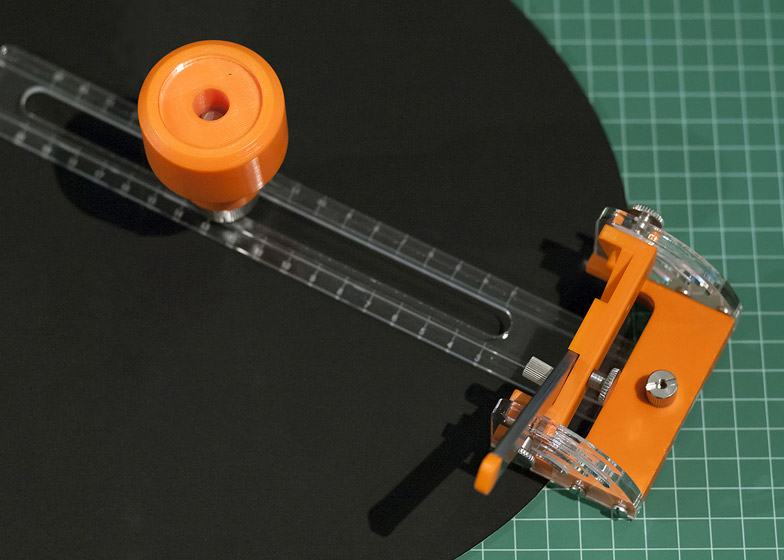

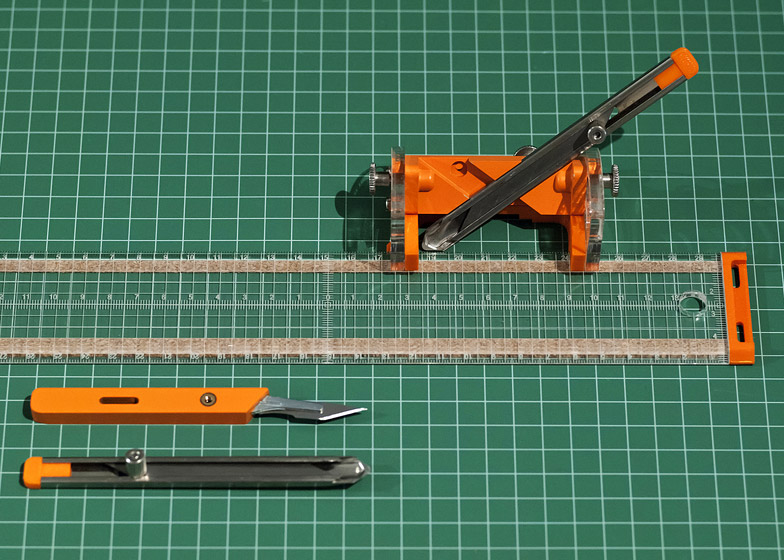

Lo's Perfect Cut range includes a scalpel, a retractable-blade knife and a rotary cutter fit into sliders, rulers and a compass-like circle tool. All of the items are designed to enable both left- and right-handed users to make accurate incisions quickly and accurately.

Lo came up with the idea after 20 years of making models and over a decade using art blades. "I found myself buying different cutters for different materials and cutting jobs, but still unable to handle them well," he said.

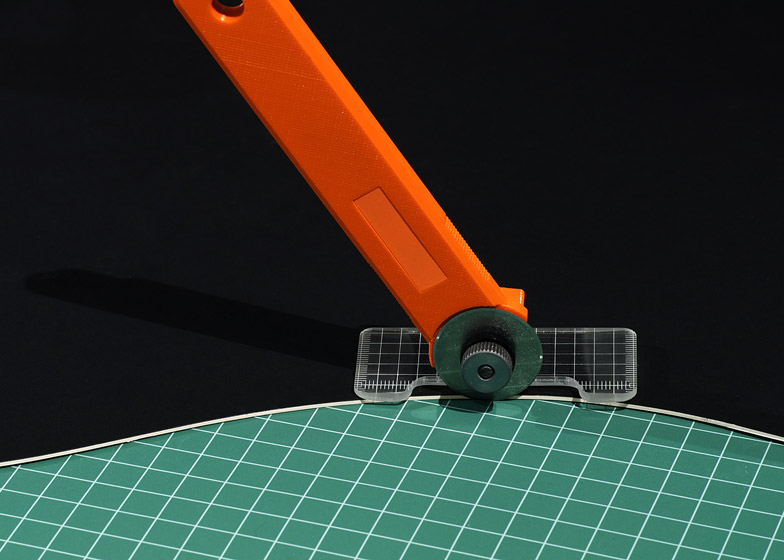

The art blades currently available either have a very specialist function, or are designed for a specific material, according to the designer. "But what if I want to cut a V-groove that is not 45 degrees, or a halfway cut along a curve drawn on a sheet of leather vertically?" Lo said. "There's nothing for that."

Although other designers have been experimenting with adapting manual tools for digital devices – including Unfold's Instruments and Archetypes project and Cameron Bowen's Parametric Tape Measure – Lo chose to focus on creating more accessible versions of existing cutting implements.

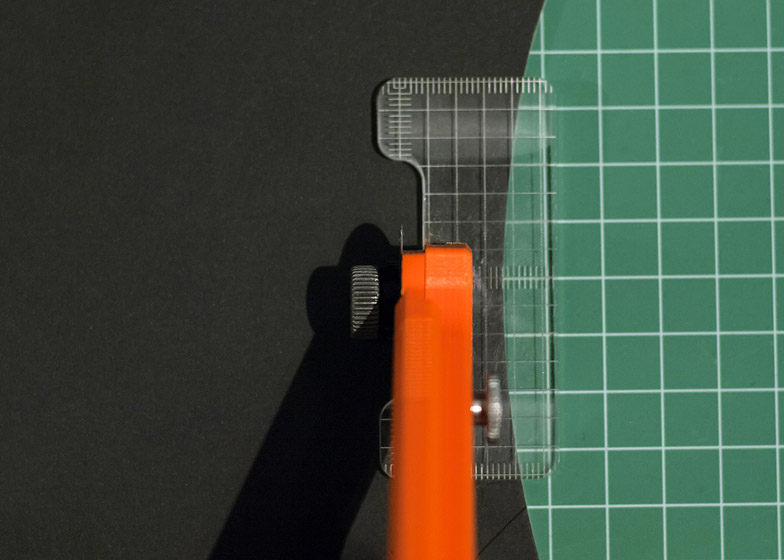

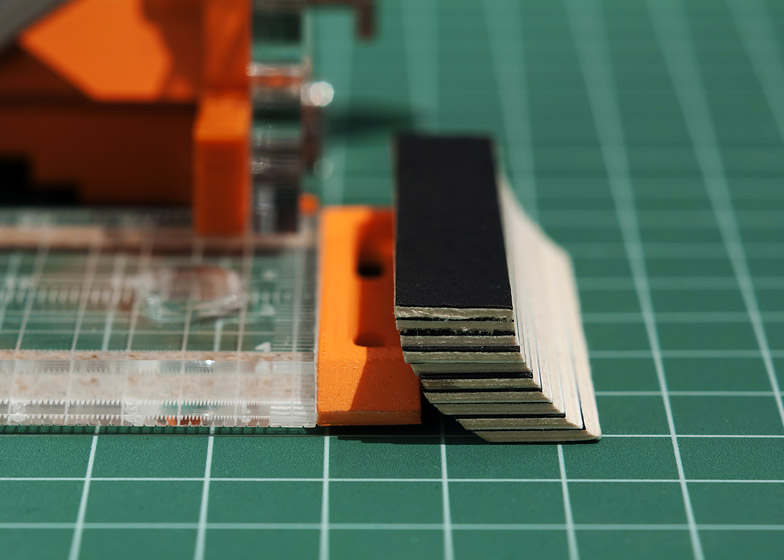

The collection started with three pieces: the ruler, the snap-off blade, and the angle slider, designed to help people create straight cuts with various angles and depths.

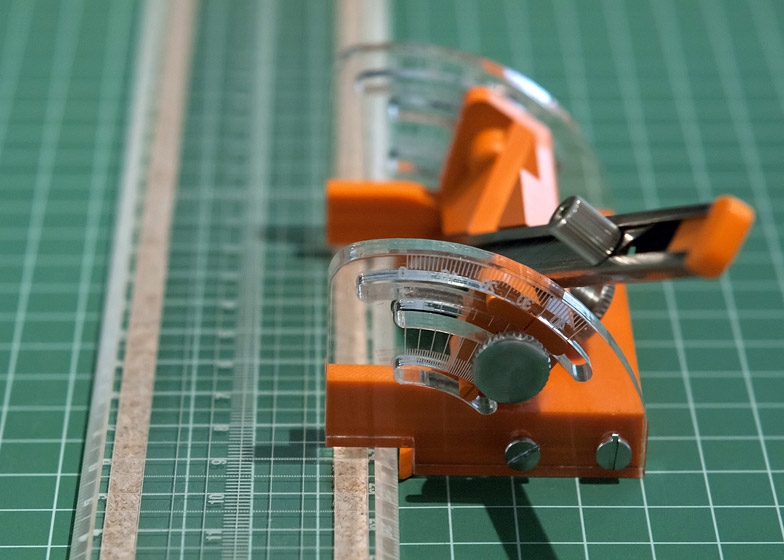

The angle slider enables the incline of cut to be controlled at five-degree intervals, and snap-off blades dictate the depth of cut.

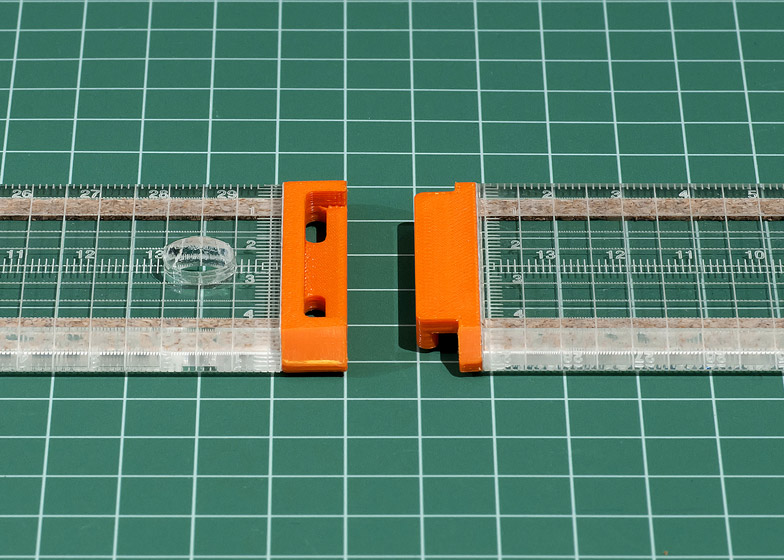

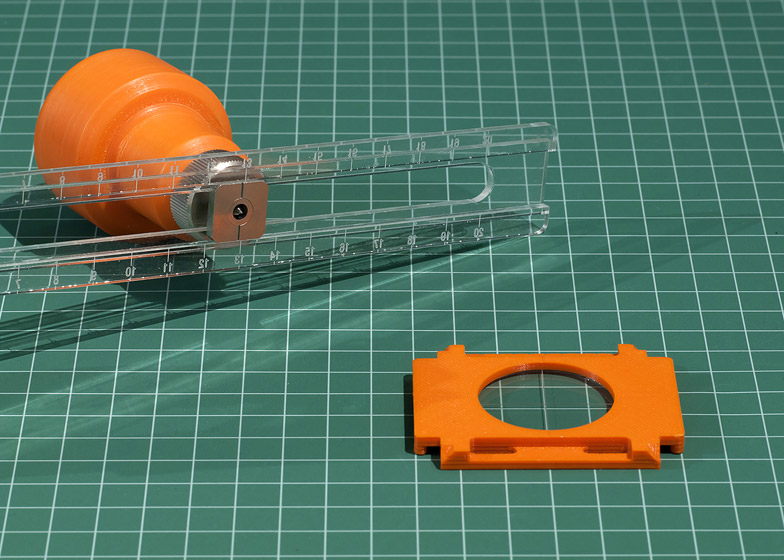

After several rounds of user testing and iteration, Lo added the fixed-blade scalpel and the rotary cutter, and a tool that can cut circles with radii of between three and 20 centimetres. He designed the rulers so they can be snapped together to form longer straight edges or right angles.

"I have tested Perfect Cut with designers of different disciplines from architecture to fashion, and with both skilled and unskilled people," he told Dezeen. "Once I've shown them how to use the tools, they can all make a good v-groove cut at various angles and a vertical cut along a spline within about five minutes."

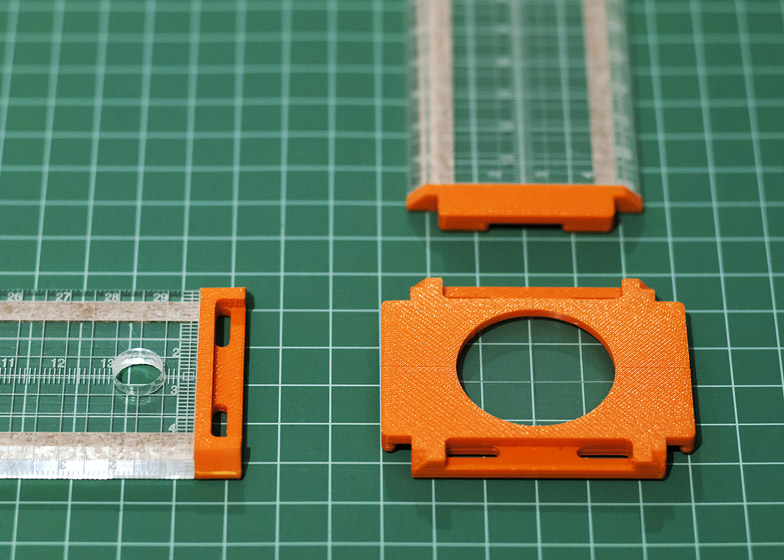

Currently a prototype developed for the designer's RCA graduation project, the tools are manually assembled from 3D-printed thermoplastics, laser-cut acrylic, stainless steel, cork matting, and off-the-shelf screws, nuts and blades. The designer envisions that the 3D-printed parts could be adapted for mass production using injection-moulding and some parts of the assembly could be automated.

The products were displayed at the Show RCA 2015 exhibition of graduate work in London earlier this summer, along with projects by other students who created tools for facilitating design.

Morten Grønning Nielsen designed a "power glove" that can be used to sculpt hard materials like stone and wood by hand, while Ming Kong focussed on digital modelling with a haptic interface for manipulating CAD models and files.