Japanese car brand Lexus used 1,700 individually shaped cardboard sheets to create a fully functional replica of its IS saloon model (+ slideshow).

Inspired by origami, the full-size sculpture was produced as a celebration of the human craftsmanship behind each Lexus car.

London-based companies LaserCut Works and Scales and Models were commissioned to complete the project, which took three months in total to finish.

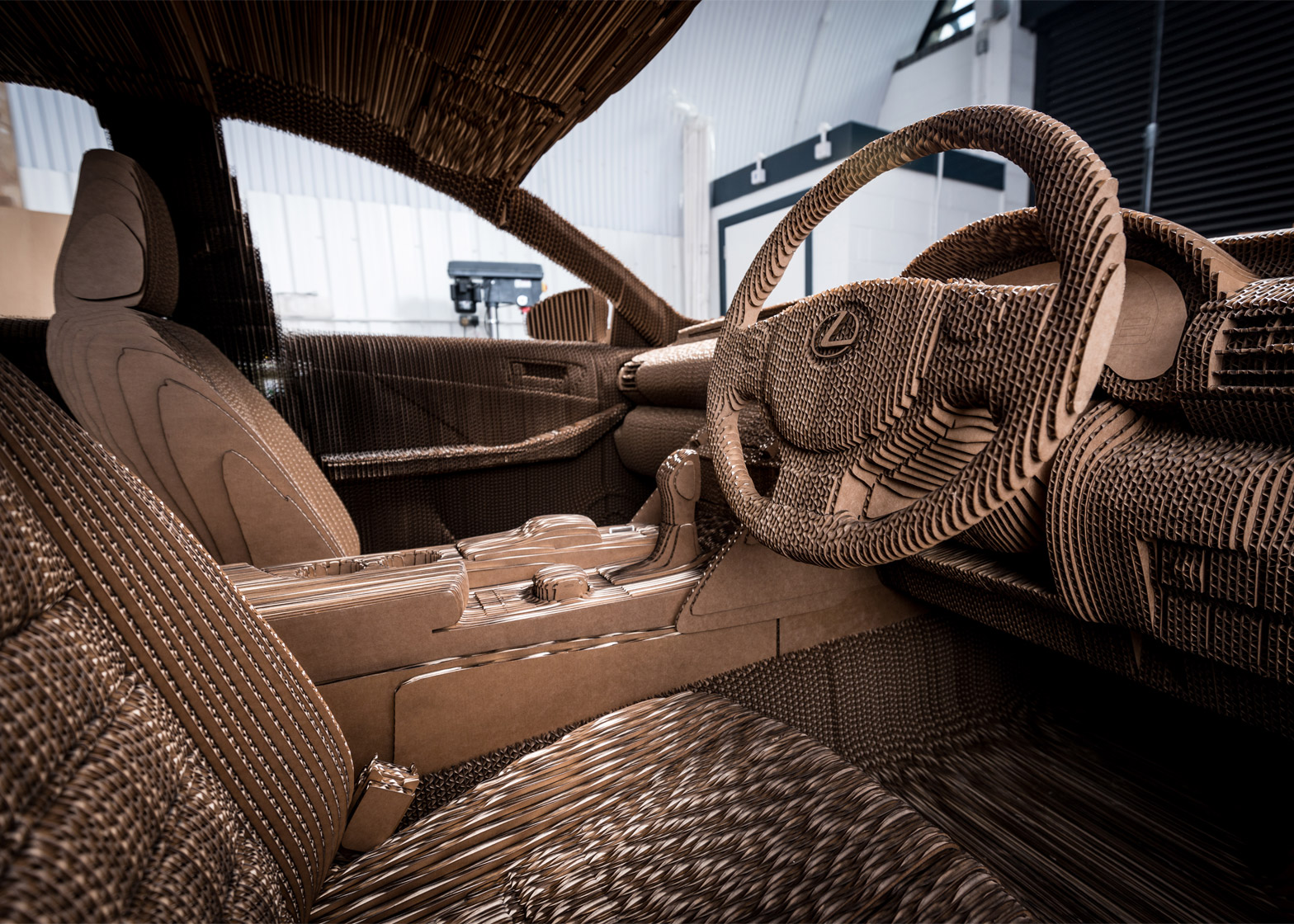

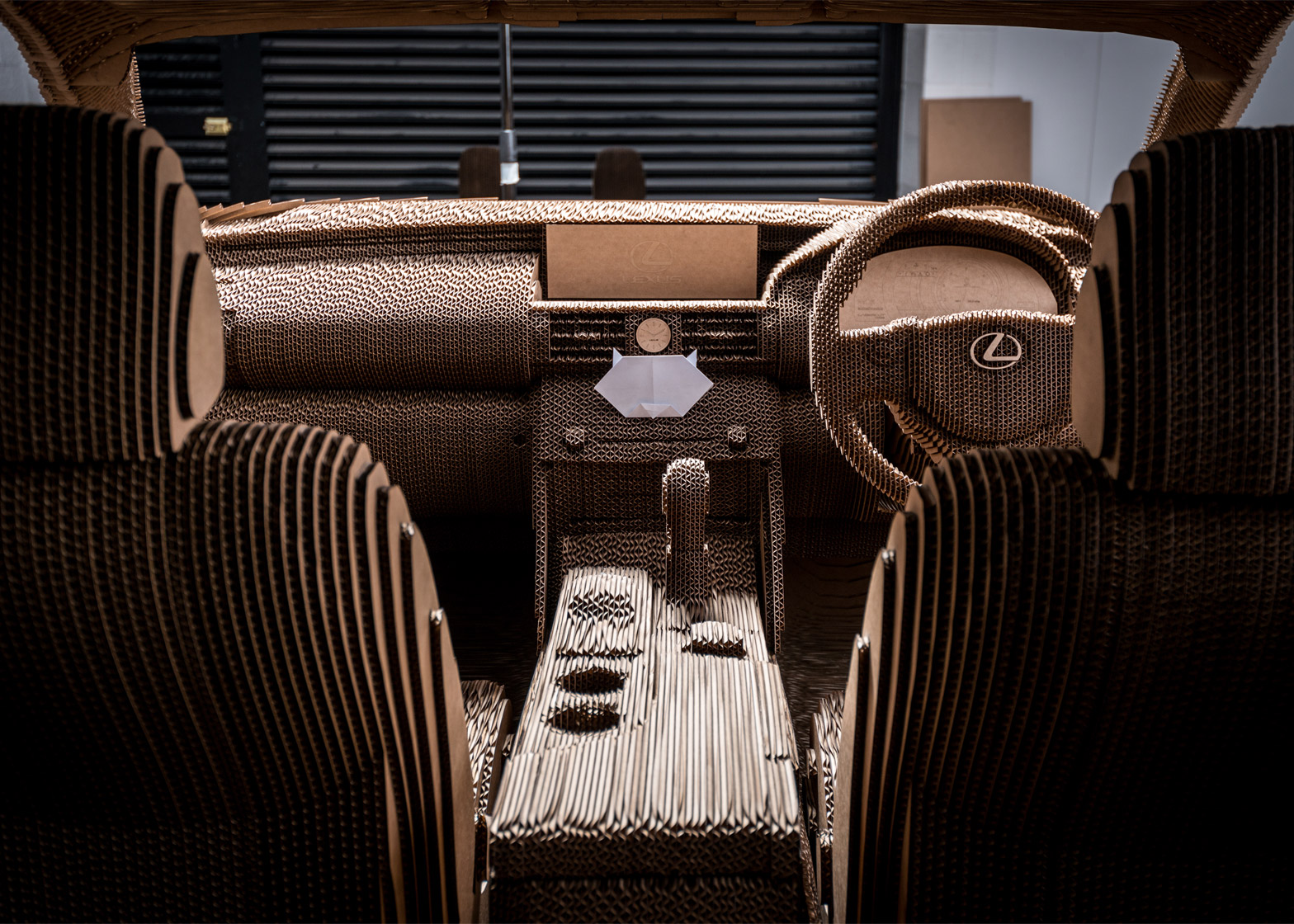

The studios were provided with a 3D model of the existing IS saloon, which they then divided into principal parts, including the main body, dashboard, seats and wheels.

These sections were digitally rendered as 10-millimetre slices, then laser cut from the cardboard and given individual reference numbers to ensure the car was assembled in the correct sequence.

Every layer was fixed together by hand using a water-based wood glue, which had to be left to set for 10 minutes after each application.

"This was a very demanding job, with five people involved in the digital design, modelling, laser cutting and assembly," said Scales and Models founder and director Ruben Marcos.

An electric motor used to power the vehicle is mounted on a steel and aluminium frame is housed within the model. The car also features a fully fitted interior, functioning doors, headlights and rolling wheels.

"The seats took a few attempts to get just right and the wheels required a lot of refining," said Marcos. "Once we could see the physical pieces taking shape, we could identify where we needed to make improvements."

"As with anything, there were some elements of trial and error, but as we had all the resources we needed in-house, this made the changes easier to produce," he continued.

The cardboard Origami Car will be on show as part of the Grand Designs Live event at the National Exhibition Centre (NEC) in Birmingham, UK, from 8 to 11 October 2015.

Earlier this year, Lexus revealed its Back to the Future-style hoverboard, which uses magnetic fields to carry its rider without touching the ground.

Cardboard has previously been used to create a waterproof bicycle that costs less than £10 to manufacture.