Designers Alexander Taylor and Joachim de Callatay have developed a special-edition version of German sports brand Adidas' Superstar trainer, featuring a seamless upper made from a single piece of leather (+ slideshow).

The project is the latest in Adidas' Futurecraft series, which aims to explore new ideas for the future of sportswear through material and process innovation. Previous outcomes have included a 3D-printed shoe sole that can be tailored to the exact contours of the wearer's feet.

Taylor's London studio, which previously created a prototype shoe for the firm featuring an upper made from recycled ocean plastic, collaborated with Paris-based footwear designer Joachim de Callatay on the Futurecraft Leather project.

The designer has worked with Adidas as a consultant since 2008, when he was involved in the development of the Primeknit shoes for the 2012 London Olympics. His idea to produce a shoe by milling leather has been in development for a long time.

"This project has been 18 months or two years in the making and when I first started I was interested in looking into the fusion of style and sport," Taylor told Dezeen. "The use of leather resonates with the heritage of the brand and we wanted to see how we could innovate with this material."

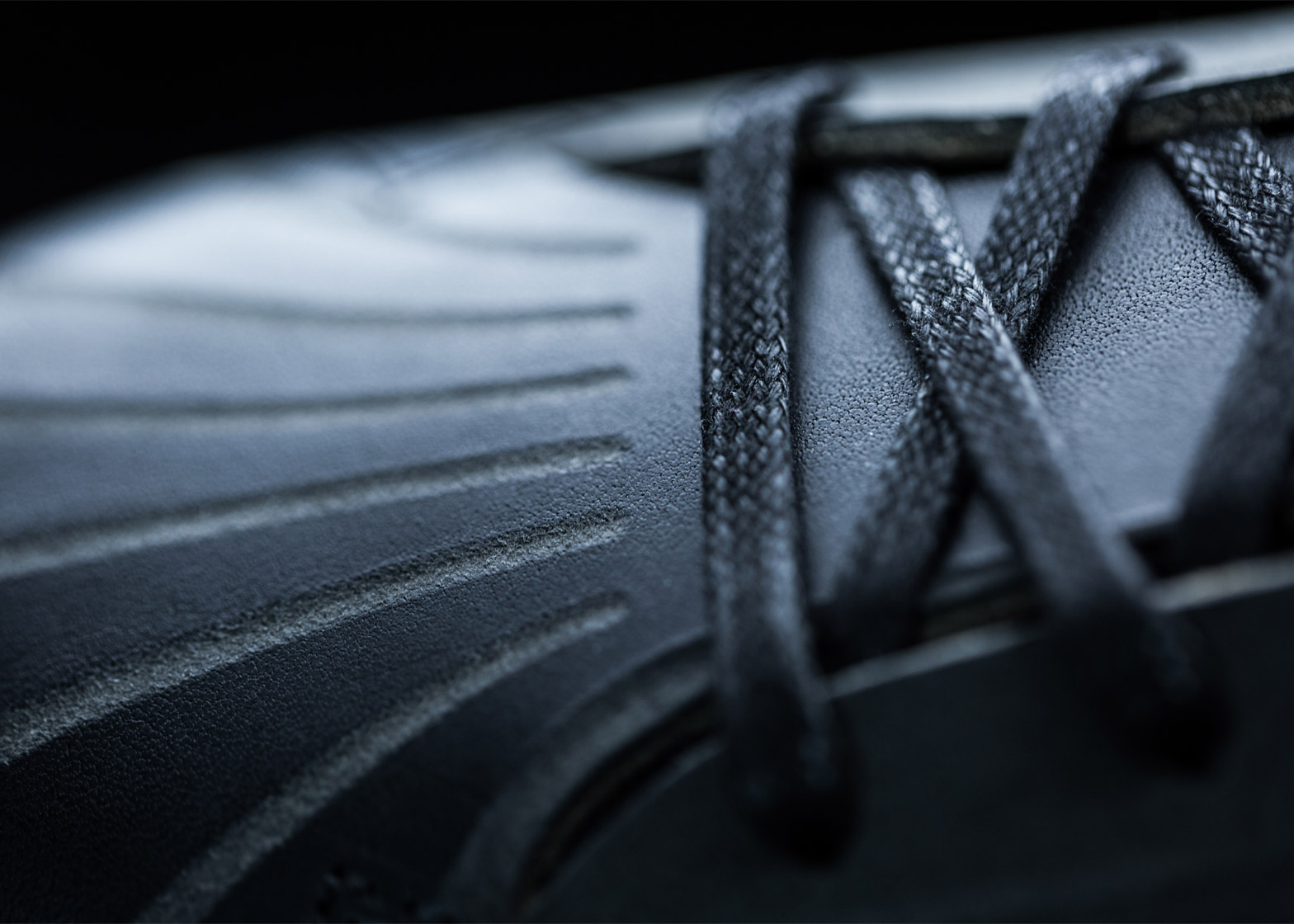

The upper part of most shoes comprises several pieces of leather or fabric fixed to the sole. But Taylor's version is made from a single sheet that is cut and carved with a pattern, which allows it to fold into the required shape.

"It fits in with the philosophy of efficiency and trying to work with and manipulate a single piece of material," he said. "By taking away the material you don't need and leaving the material you need, it falls into the idea of trying to find intelligent ways of working with materials."

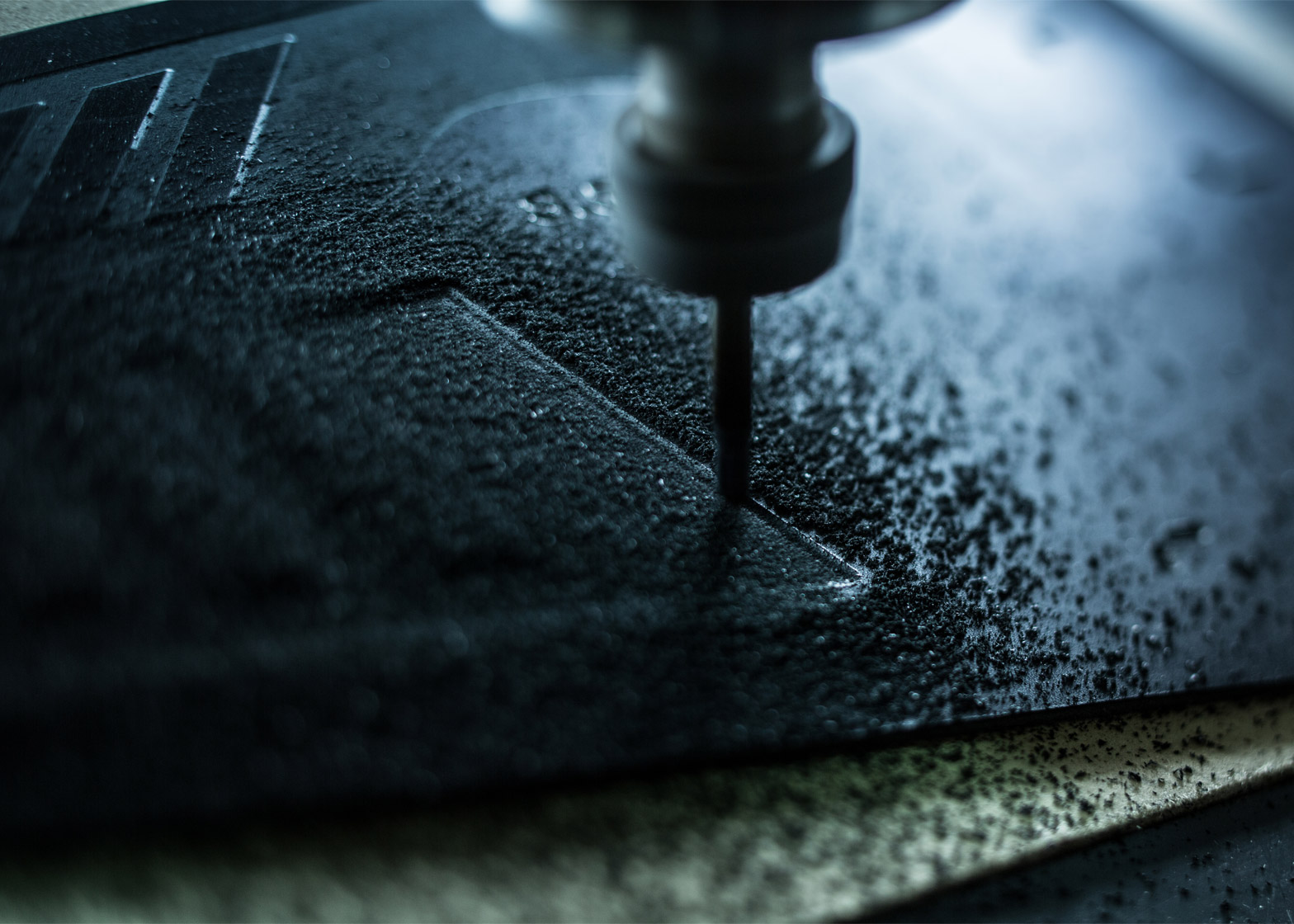

The pattern is made using a computer-controlled milling machine, capable of accurately removing a thin layer from the surface of the material. This gives rigidity and flexibility in the appropriate places.

"Joachim and I discussed traditional making techniques and ways of removing the leather through skiving," said Taylor. "We identified that removing material from the surface of the shoe creates benefits because it becomes more flexible and breathable and also reduces the need to build up the material to create support zones."

The milling technique is more conventionally used in industrial manufacturing to produce components from materials such as metal, polymer or resin, but Taylor said it was ideally suited to this process.

"It's a process that is already commonly used in factories but we wanted to find a way to re-appropriate it for another purpose," the designer added. "When you take a machine that is usually calibrated to cut certain materials and then you ask it to cut different materials you have to figure out how to do that through trial and error."

Adidas claimed that the process could enable shoes to be custom-made to individual preferences by inputting the wearer's biomechanic data – obtained by monitoring the body while active – and removing material to optimise support where it is most needed.

"It allows a level of precision and control that could be of benefit to the wearer or athlete," Taylor said. "It also falls into the rhetoric of local manufacturing and being able to offer a more bespoke service."

"Because there's no heavy tooling it's relatively easy to change the pattern you're cutting so you can imagine how it could be customised for style or for performance," he added.

The Superstar was used as the platform for the project because the design is 45 years old this year, but Taylor said he is working on applying the technique to some of the brand's other models. Forty-five pairs of the special edition Futurecraft Leather Superstars were made available at the Dover Street Market stores in New York, London and Tokyo on 7 November 2015.

Earlier this year, Adidas executive board member for global brands Eric Liedtke told Dezeen that the brand aims to use design to challenge its arch-rival Nike as the dominant brand in the American market.

Its other recent innovations include a shoe that combines a knitted upper with a midsole made using a plastic foam cushioning material.

Images are courtesy of Adidas.