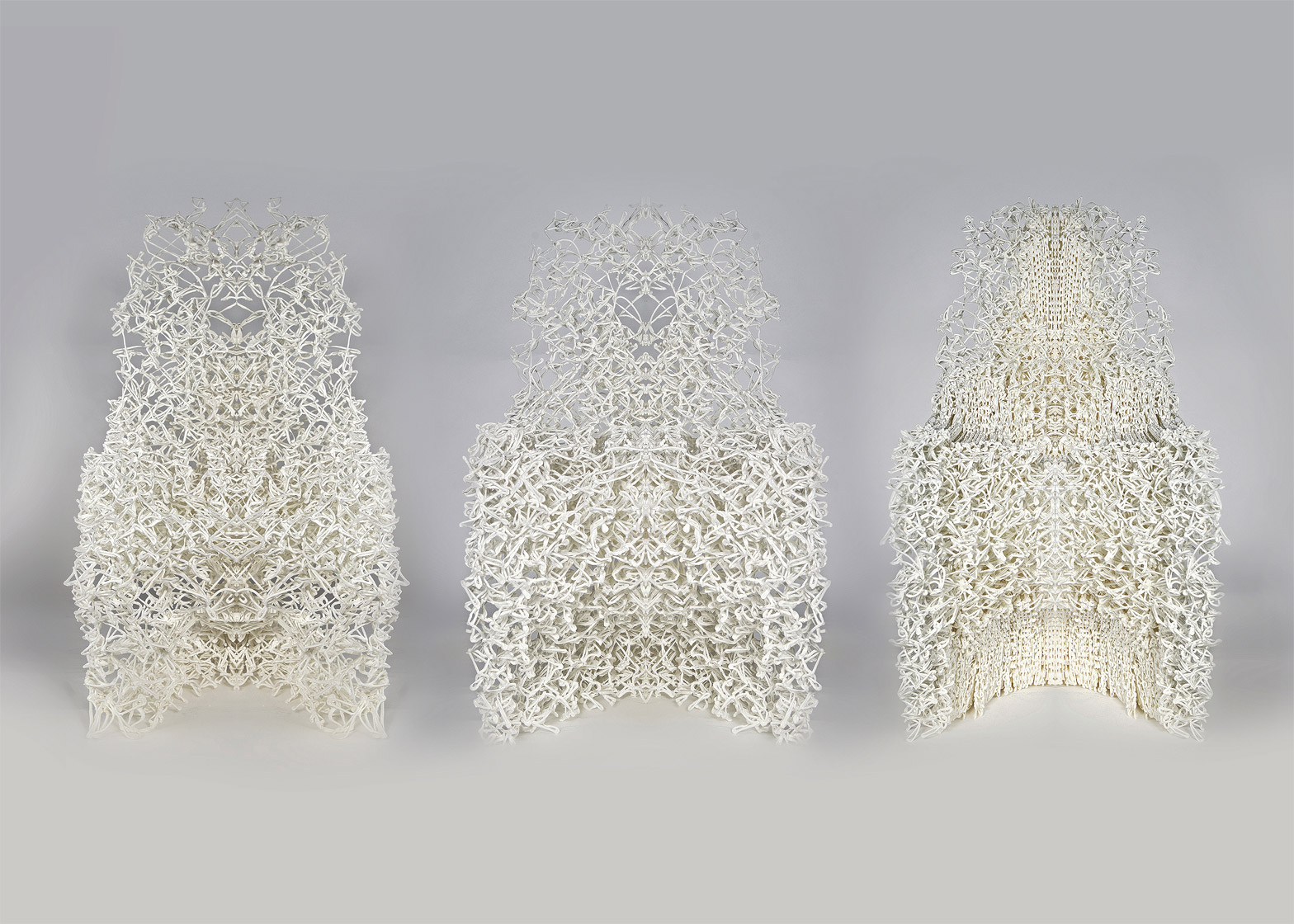

A team of students at the Bartlett architecture school have developed a technique for 3D printing complex curved structures, and used it to build a set of intricate chairs.

The Spatial Curves project was completed in Research Cluster 4 at The Bartlett School of Architecture, part of University College London.

Team CurVoxels – made up of Hyunchul Kwon, Amreen Kaleel and Xiaolin Li – set out to create a new method of using robots for large-scale 3D printing.

Working under the direction of tutors Manuel Jiménez García and Gilles Retsin, the team started with used cantilever or S-shaped chairs by designers including Marcel Breuer and Verner Panton as their starting point.

"CurVoxels questions how the cantilever chair would develop when confronted with a new fabrication technique like robotic 3D printing," said the group.

The team developed a custom nozzle that can extrude four- to six-millimetre-thick wires of plastic filament in the air, avoiding layered printing.

"The industrial robot drags plastic from the extruder in the air where it is cooled down," said CurVoxels. "This method allows us to print faster, use less material, and achieve filigree-like structures with a high degree of detail."

To demonstrate the process, a digital model of the Panton chair was divided into three-dimensional pixels known as voxels.

The pixels were then used to generate a pattern of curves that the robotic extruder can follow.

The team also developed a digital technique that uses an algorithm to combine a single curvilinear element into a continuous extrusion. This allows the robot to print uninterrupted, and the designers to alter the patterns using an app.

By altering the filagree pattern, the team are able to change the density of key parts of the chairs to improve structural integrity.

Spatial Curves was presented at the Bartlett's B-Pro Show 2015 graduation exhibition in London and the Synthetic 2015 Exhibition in Le Mans, France.

Other teams of Bartlett students have also developed alternative techniques for producing furniture.

One group used a composite material of felt and resin to make self-supporting chairs, another used cement-covered foam pipes to create Gothic-style structures, while a third 3D-printed concrete to form large furniture pieces.

Large-scale 3D printing is developing rapidly as designers experiment with various materials and techniques.

People in the Netherlands will soon be able to cycle over the world's first 3D-printed steel bridge on the world's first 3D-printed steel bicycle, thanks to technology developed by MX3D.

Also, a 3D-printed bioplastic was recently used to create a sculptural facade for the building where European Union meetings take place.

Photography is by Sin Bozhurt and Team CurVoxels.

Project credits:

Team CurVoxels: Hyunchul Kwon, Amreen Kaleel, Xiaolin Li

Tutors: Manuel Jiménez García, Gilles Retsin, Vicente Soler Senent, Research Cluster 4 at UCL the Bartlett School of Architecture