London design studio PearsonLloyd has added to its Intelligent Waste collection of rubbish and recycling bins for kitchenware brand Joseph Joseph.

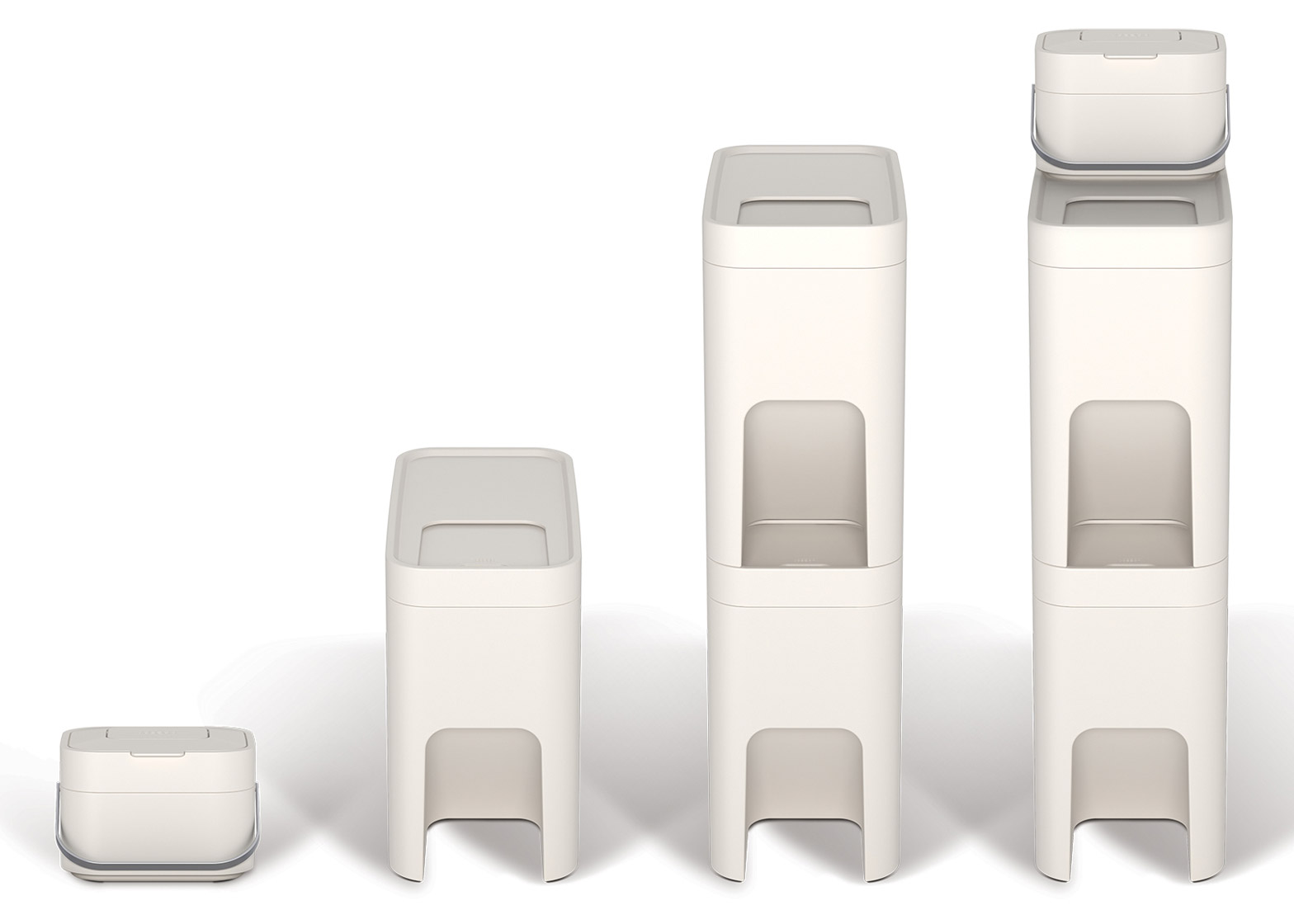

The new Stack and Stack 4 waste disposal systems follow the studio's 2014 Totem with a slimmer, plastic design and a focus on compostables.

The collection aims to address the proliferation of bins in the home as recycling collection programs expand and the management of food waste becomes a new concern.

To cut down on the floor space commanded by multiple bins, Intelligent Waste units stack vertically while maintaining easy access to each receptacle with a variety of openings.

"When we conceived of the range, the key observation was that people needed multiple waste separation opportunities, which meant access to each bin," said Luke Pearson, co-director of PearsonLloyd.

"Typically this means you simply have to place the elements side by side, which wastes floor space," he told Dezeen. "As we all know, floor space is becoming ever more precious, so our products allow the divisions to happen within a single vertical volume horizontally, thus halving [the required] floor space."

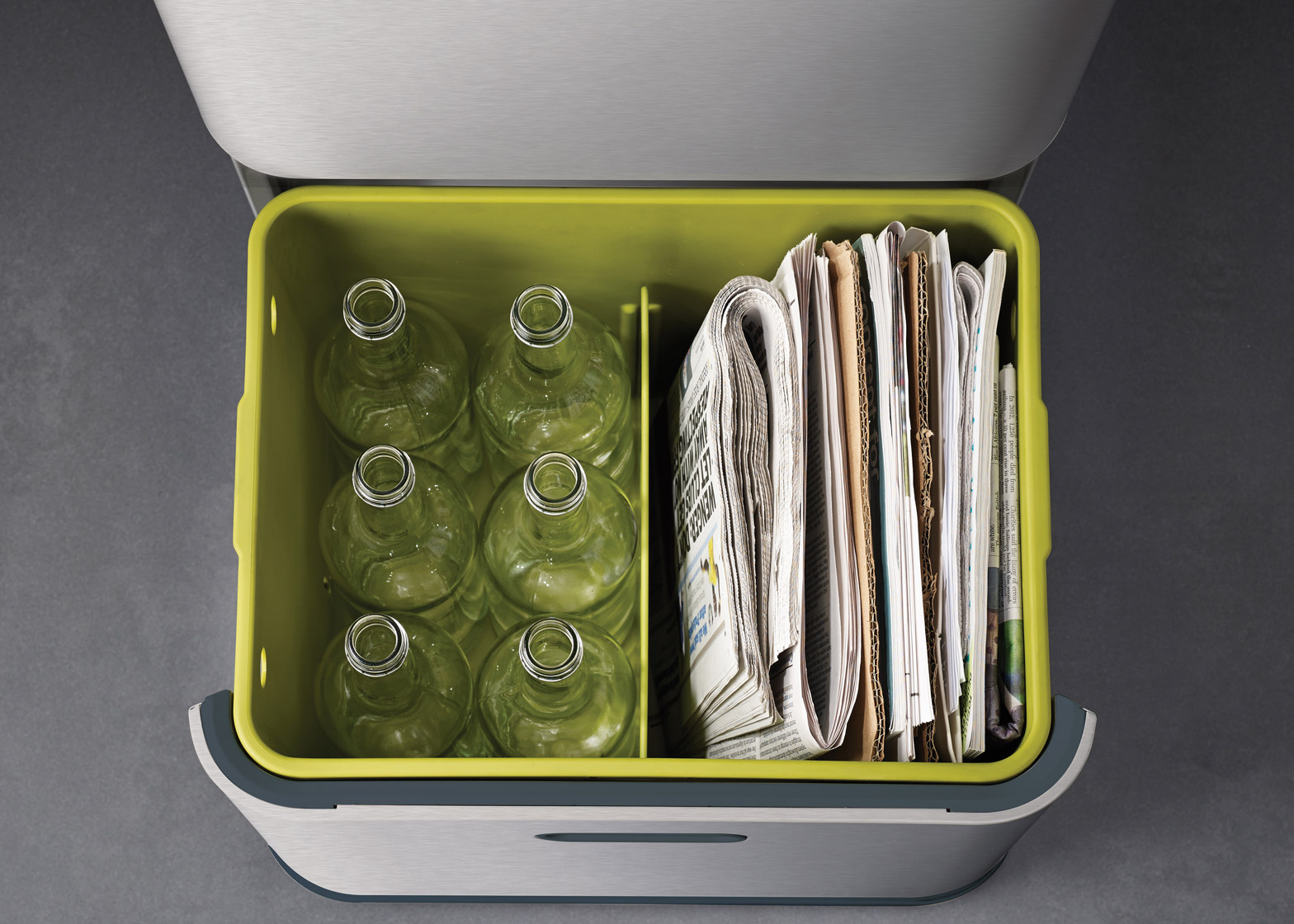

The steel-bodied Totem produced by Joseph Joseph allows access to its upper section from the top, while the lower section opens out like a drawer – it can even be removed and wheeled into a separate room.

According to Pearson, there are further incentives to arranging the bins horizontally.

"It means the bin compartments are shorter and wider, which makes lifting and carrying easier, and bags use less plastic and are easier when full to pull out of the plastic bin elements, having less suction and depth to lift," he said.

The two-level Totem can be further subdivided to separate four types of waste, including compostables, for which there is a specially designed caddy.

The materials – stainless steel for the body, polypropylene and ABS plastic parts for the inner parts – were chosen so they would be durable as well as easy to separate and clean.

Stack, meanwhile, is named after its stackable units, which maintain access to each level through a hollow in their ABS plastic exterior.

Each unit has a sliding lid, a removable inner bucket for easy disposal and colour-coded tabs to categorise recycling types.

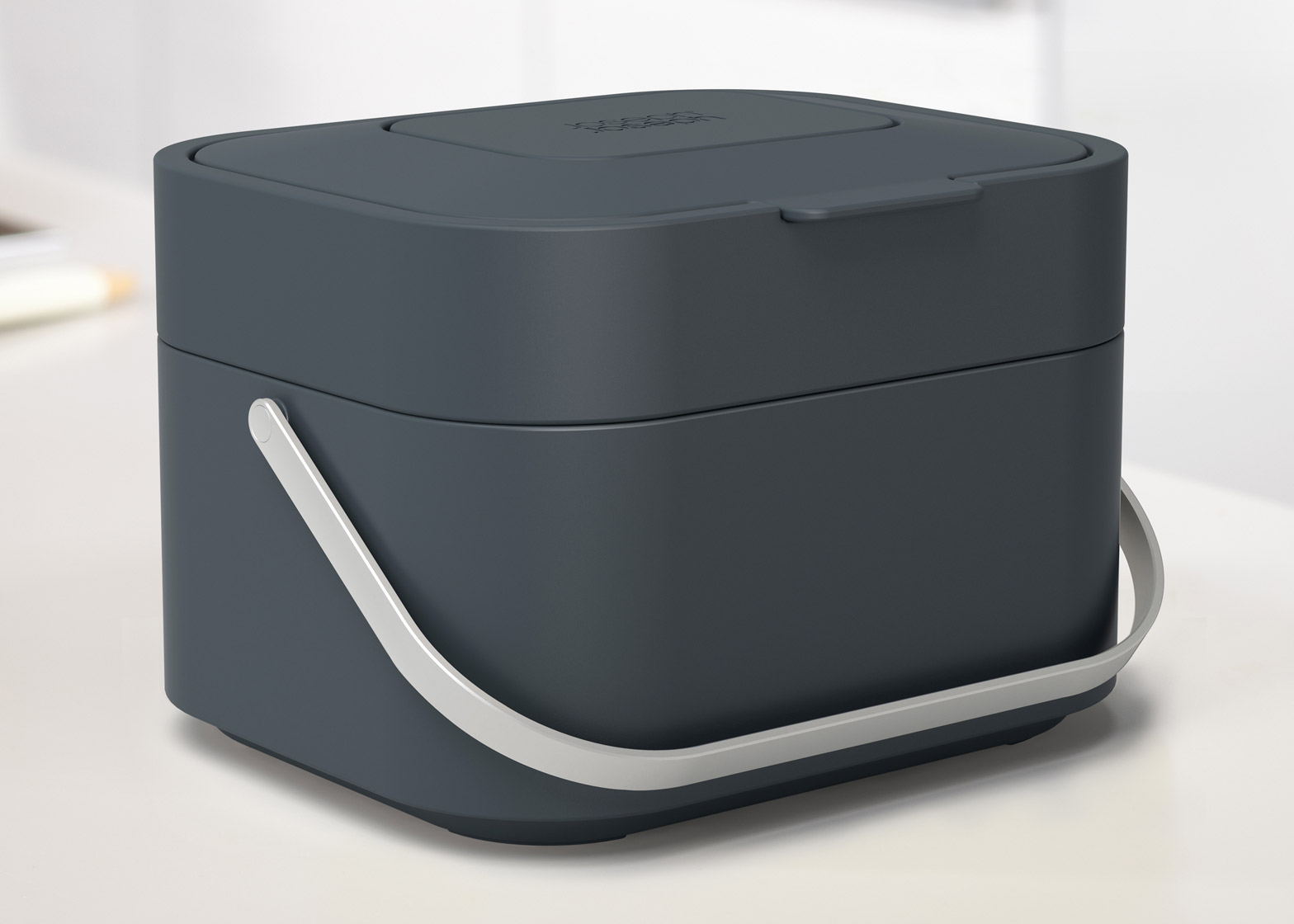

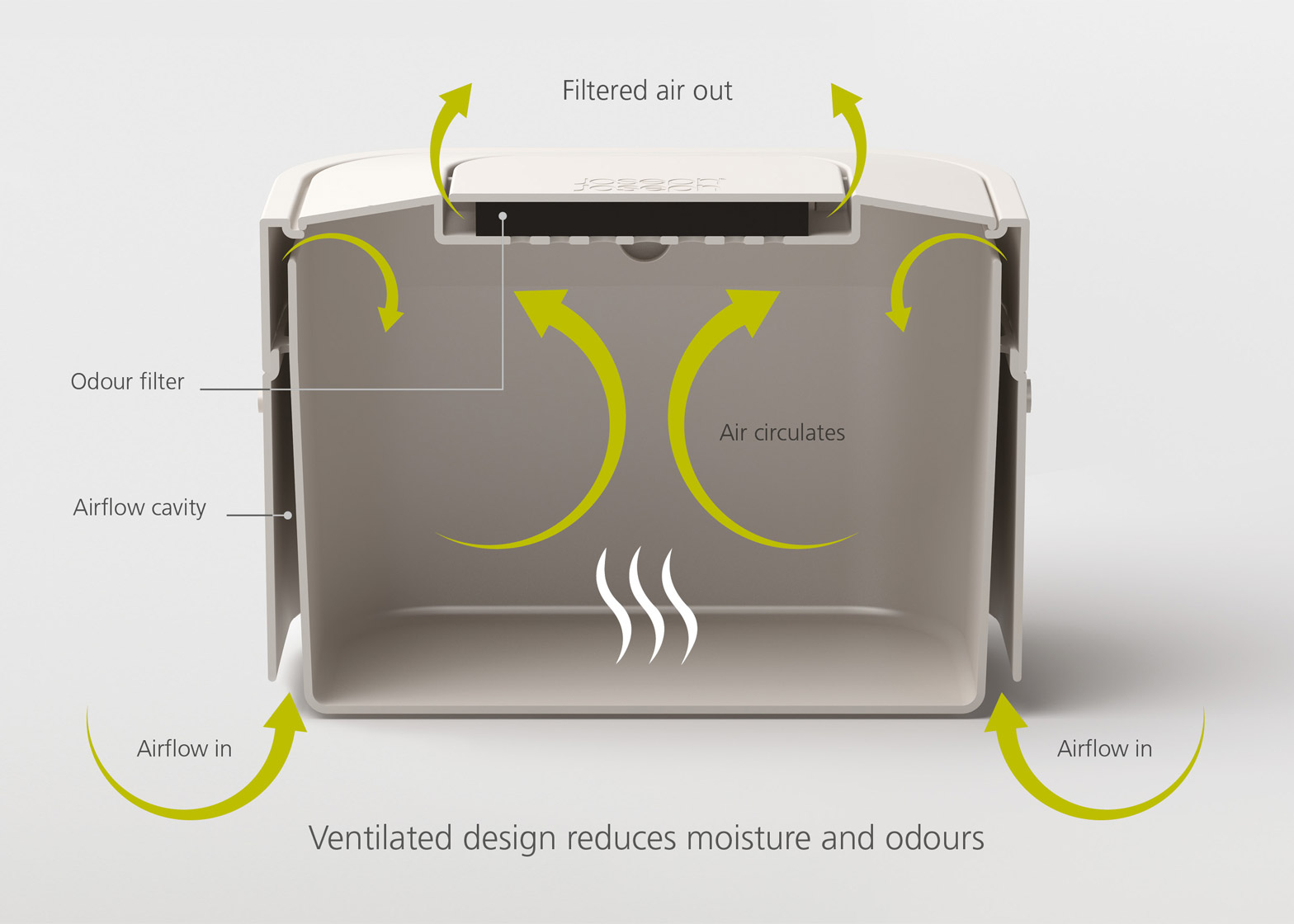

The third product in the range is Stack 4, a food waste caddy that can be used together with other Intelligent Waste products or on its own.

With its ventilated outer shell and integrated filter, the steel-handled, polypropylene-bodied bin is designed to minimise odours and prevent moisture build-up.

The Intelligent Waste series comes at a time when consumers are looking for more sustainable ways of living, including spending more time and money on their household rubbish and recycling.

"People care more than they did a few years ago, and there is a growing awareness that we should separate our rubbish in the home and recycle," said Pearson.

"Landfill is a terrible idea, and apart from using less, we have to work towards a closed-loop production eventually."

"Our rubbish collection process can sort multiple materials, and as the cost of raw materials will inevitably rise, there is also secondary business here," continued Pearson.

Driven by consumer demand, industries and technologies around waste disposal are growing fast.

One technology that's emerged into this new space is Dutch designer Dave Hakkens' Precious Plastic machines, which anyone can build and use to turn used plastic into new products.

Blueprints for the machines, which the designer described as "a solution to plastic pollution", are available online for anyone to download and build.

American college student Tyler McNaney has also invented a desktop machine that makes the raw materials for 3D printing by grinding up waste plastic from bottles, wrappers and even Lego bricks.

This idea has been formalised more recently by Coca Cola and music producer Will.i.am, who developed a 3D printer that produces objects using filament made from recycled plastic bottles.