London Design Festival 2016: the frame of this simple chair by designer Samuel Wilkinson is made using the traditional technique of steam-bending wood (+ slideshow).

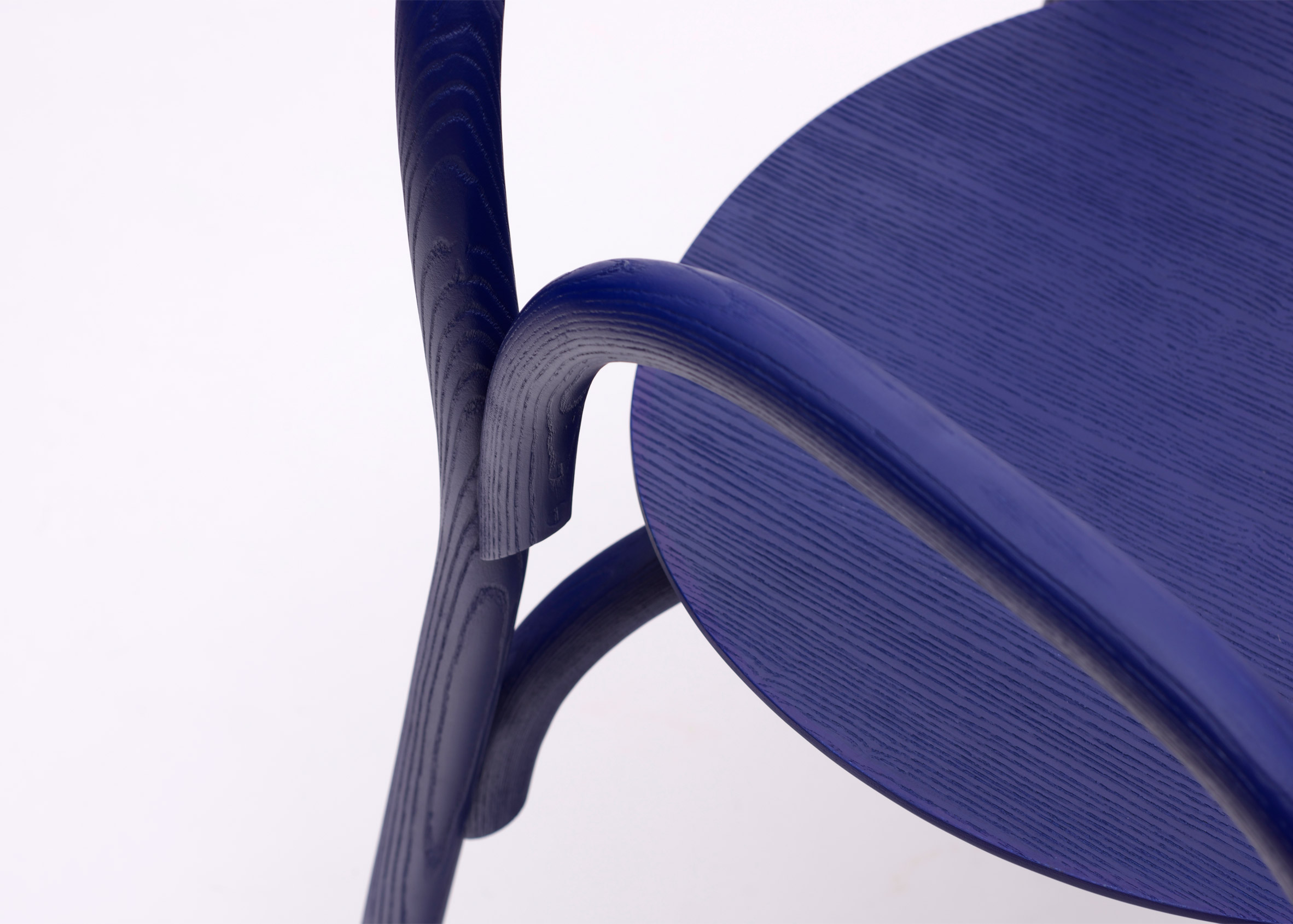

The Brace chair gets its name from arch braces, the curved pieces of wood used to strengthen a structure.

Wilkinson has made the frame of the chair almost entirely of steam-bent arch braces, negating the need for any additional support.

The wooden seat is placed in the middle of the frame, allowing the chair to remain minimal and appear simple in construction.

"Steam-bending wood is a traditional process steeped in history," said Wilkinson. "It is low energy, ecological and a truly economical method for manipulating wood."

"It has a reduced scrap rate since smaller pieces can be bent into shape rather than machined from larger blocks."

The steam-bending technique was pioneered by the original Thonet brand, which was established by German designer Michael Thonet in 1819.

The technique can be seen in many of the brand's products, like the cafe-staple Thonet No 14 chair, produced today as the 214 chair.

When manufacturing the Brace chair, Wilkinson used locally sourced materials and a factory that is within 100 miles of his east London studio.

"There are only a small number of skilled manufacturers who can produce steam-bent products on any scale, and these are expensive due to rising labour costs and the handmade discipline required," he said.

The Brace chairs will be available heavily sandblasted to make the wood grain prominently visible. They will be available in a variety of finishes, including matt black, cobalt blue and lime-washed ash.

Brace launched at the Design Undefined exhibition during this year's London Design Festival, which takes place until 25 September.

Other designers launching products at the festival include Bert & May, which debuted a range of handmade tiles featuring simple geometric shapes, and Bethan Gray, who has designed brass-patterned furniture based on the architecture of Oman.