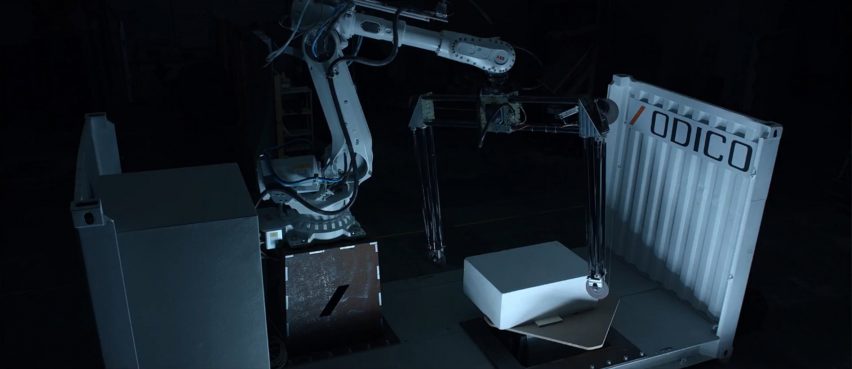

Odico's Factory on the Fly is a pop-up robotic manufacturing unit for construction sites

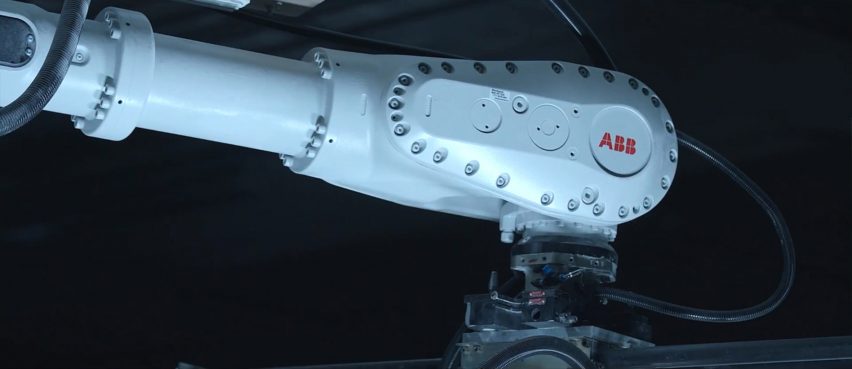

Danish company Odico is preparing to launch a mini all-in-one robotic construction system that can be sent to building sites inside a shipping container.

Factory on the Fly is a mobile system that promises to make it possible for even non-specialist workers to instruct robots to fabricate building components on site.

Odico chief technology officer Asbjørn Søndergaard describes it as a "plug and play solution" that is as simple to use as using any tablet app.

"Factory On The Fly enables on-site, parametric production of advanced formwork and custom building components," Odico chief technology officer Asbjørn Søndergaard told Dezeen. "It is operated from a standard iPad, allowing for simple interaction and operation by non-specialist personnel."

"It bypasses the current technocracy of robot manufacturing and replaces it with a straightforward user experience, the simplicity of which is on a par with using conventional tablet apps," he said.

Factory on the Fly is currently a prototype, which Odico is working to have on sale in the first half of 2019. The company raised £3.6 million of investment to put towards the product when it went public on the Nasdaq First North stock exchange in July.

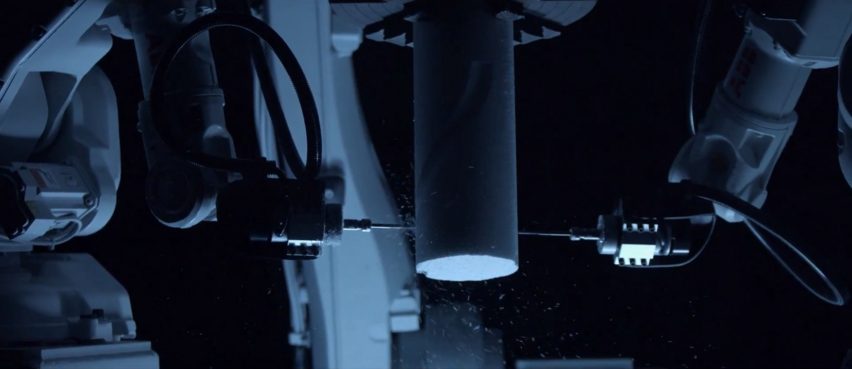

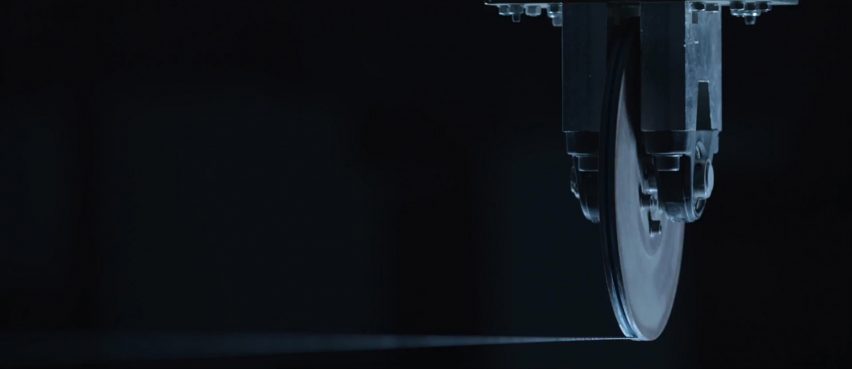

The mobile factory is an evolution of Odico's existing offerings, which focus on robotic construction methods including hot wire and abrasive wire cutting.

Its technologies have been used by studios including Zaha Hadid Architects, 3XN, BIG and Dorte Mandrup.

One of its recently completed projects is Studio Olafur Eliasson's castle-like Fjordenhus Kirk Kapital offices, which Odico says marks the first time a building has featured load-bearing concrete structures made using robotic wire-cutting of expanded polystyrene (EPS) moulds.

Factory on the Fly will pack this technology, and Odico's others, into one unit that fits into a standard three-metre-long shipping container for easy transportation around the world.

Among the tasks the factory is equipped to carry out are formwork production, reinforcement bending and sheet cutting.

It can customise and manufacture building components on the fly, or realise more advanced concrete structures using production files created at Odico's headquarters as part of its formwork services.

As well as edging out conventional production methods in terms of time and cost, these robotic processes allow for the realisation of designs that are geometrically complex. When they become widespread, Søndergaard said we'll see "an enrichment of the built environment".

Other recent architecture works to involve robotic construction include a Carlo Ratti Associati university campus, the showcase DFAB House built by ETH Zurich and a 3D-printed steel pedestrian bridge by MX3D.