Eindhoven-based designer Thomas Vailly explores turning sunflower crop waste into bio-materials to make sustainable products from insulation panels to iPhone cases.

Thomas Vailly, founder of Studio Thomas Vailly (STV), teamed up with scientists from the Ecole Nationale Supérieure des Ingénieurs en Arts Chimiques Et Technologiques (ENSIACET) laboratory to develop a series of materials using only sunflower bio-matter.

Commonly grown to produce oil, seeds or bio-fuel, sunflower farming produces agricultural waste that has the potential to be made into valuable resources.

Vailly wanted to put every part of the sunflower crop to use, using the left over from the harvest to create both a sustainable material as well as a non-synthetic binder and a non-toxic varnish.

"The rules were simple, we can only use sunflower by-products, no added ingredients," said Vailly. "We work by focusing on one plant at a time – being so specific and constrained allows for exciting findings."

For instance, the press cake – a concentrated substance left over after extracting oil out of the seeds – can be used as animal feed, but it can also be turned into a water-based glue, or can be heated and pressed down into a thin film-like material that resembles leather.

Instead of leaving the stalks to decompose in the field, as would normally happen, Studio Thomas Vailly organises a second harvest to collect them, and separates them into bark and marrow.

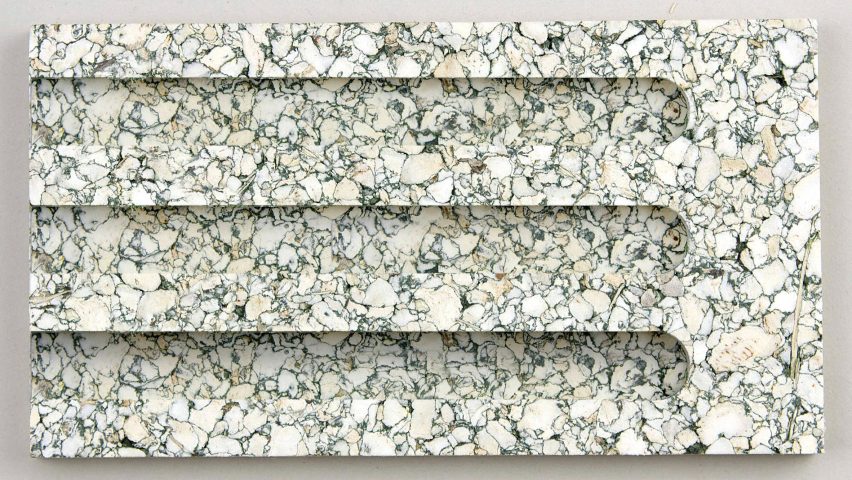

The bark fibres are heated and pressed into hardboard, while the marrow is combined with the water-based glue made from the sunflower seeds to form a light and foamy composite material that acts as a natural alternative to polystyrene.

This glue extracted from the seeds can be used as an adhesive to assemble the different bio-based materials, which can then be coated with sunflower varnish to make them resistant to water.

"The sunflower crop offers a unique range of bio-based and biodegradable material," said Vailly. "Entering the realm of bioplastics, a vast number of applications of what was previously considered waste becomes possible: from a tiny bolt to a large insulation panel, from a bio-board to an smartphone case."

"What is important to keep in mind is that these bio-based materials are different from what the industry and consumers are used to," he added. "Bio-based materials are not to be seen as a replacement for their synthetic counter parts, they have different qualities that can be exploited."

Vailly envisions the bio-material being transformed into an array of items, from packaging and throw-away tableware to office furniture and acoustic panelling systems.

"To me, it is only rational and logical to look at the resources we do not use – which are wrongly called waste – and be creative with them," said the designer.

"Why use oil-based adhesive to glue sunflower particles when you can extract all necessary ingredients from the local field itself? It is following the same logic as what our ancestors were applying by necessity: make maximum use of what is in front of your nose," he continued.

The project was funded by Atelier Luma, which will form part of the Luma Arles arts complex. The reflective aluminium building that will house the arts centre has been designed by Frank Gehry and is due to open in Spring 2020.

In a similar project, a team of British and French researchers developed a new version of the ancient building material cob – made of a mixture of water, soil and fibres like straw and hemp – as an environmentally friendly option for homes.