3D printing meets felt in new additive manufacturing technique

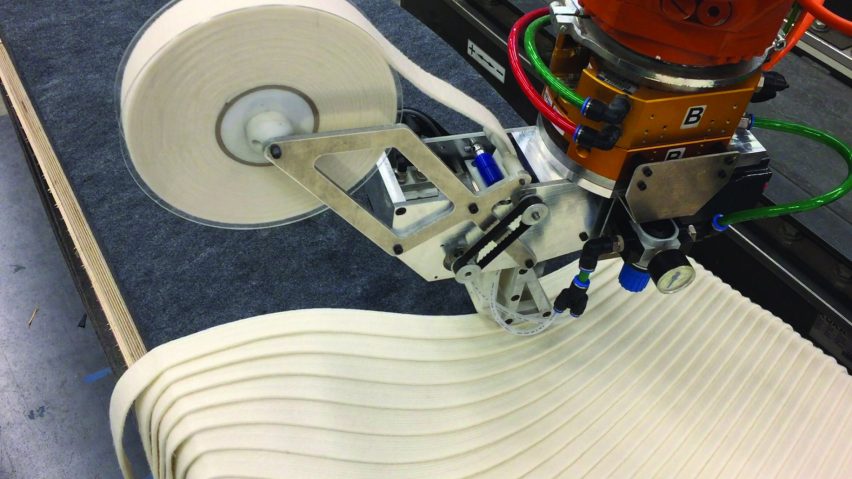

Acoustic panels and other architectural elements can be made in complex 3D forms using a robotic needle felting process developed by researchers at the Taubman College of Architecture and Urban Planning in the US.

Wes McGee, Tsz Yan Ng and Asa Peller liken their process to 3D printing, or additive manufacturing, because it also involves the digitally engineered layering of material.

And just as those processes have allowed for the creation of more geometrically complicated forms in materials such as plastic, concrete and even living tissue, the team's robotic process opens up new opportunities for felt.

Made from either wool, polyester or a blend of the two, felt is a textile that is made by bonding rather than weaving layers of material together. Typically, this is done through needle felting, where barbed needles punch through the layers, tangling the fibres together.

On an industrial level, this work is already done by machines, but the Taubman College team enhanced this process with some advanced technologies.

It means that the kind of products that are now made of felt — which, because of its sound-dampening properties, is particularly popular in acoustic panels — could be made in more complex shapes, and with sophisticated or customised properties built into their form.

For starters, their tool felts in three dimensions rather than two. This not only allows for the production of sculptural elements, it also means that a felt panel can have different properties within it, even if no differences are visible on the surface. For instance, it might be more stiff in certain areas.

The team believes this could be particularly useful in the production of bespoke acoustic solutions for open-plan offices, and plan to focus on this in their next stage of research.

The project has been shortlisted for a Dezeen Award 2019 in the workplace design category.

As with other forms of robotic manufacturing, there's also improvements to precision and speed.

The Taubman College team invented both the tools and the digital workflow to realise their robotic needle felting technique. They applied them to create several prototype panels as well as a round pouffe.

The prototypes explore three different felting techniques — quilting, shiplap (a method of overlapping commonly used in timber planks) and shingle (with overlapping tiles).

The team noted that while additive manufacturing processes had revolutionised several industries, textiles had so far been relatively untouched, with the exception of 3D knitting such as in Moroso's Cradle Chair and Nike's Flyknit.

"While notable CNC examples exist, such as weaving and 3D knitting, these processes impose limitations on the resulting part thickness and fibre density," said the team.

"Given the unique capacity of felt to be seamlessly 'added' into a cohesive solid, it presents a unique opportunity to investigate the potentials of an additive manufacturing approach."

They said that the project had allowed designers and roboticists to collaborate on novel designs "never seen before".

"What this manufacturing process produced was unique in terms of aesthetic experience, efficient in terms of manufacturing, and as a process, scalable to other applications," they said.