MIT creates reprogrammable ink to make objects change colour

Consumers could change the colour of their cars, shoes, clothes or other belongings at will, using a new light-responsive ink from the Massachusetts Institute of Technology.

Dubbed PhotoChromeleon, the "reprogrammable ink" gives objects the ability to change colour and pattern when exposed to light of certain wavelengths.

The change is reversible and repeatable – users could update their items every day, if they wished – and the colour would stay fast in ordinary settings.

PhotoChromeleon is the invention of MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL). Its researchers believe the ink could help reduce waste by reducing the demand for new goods.

"Countless resources could be preserved"

People could update older items once they tired of their original colour, and manufacturers could cut down on overproduction.

"This special type of dye could enable a whole myriad of customisation options that could improve manufacturing efficiency and reduce overall waste," said CSAIL postdoctoral researcher Yuhua Jin, lead author on a paper about the project presented at the ACM Symposium on User Interface Software and Technology.

"By giving users the autonomy to individualise their items, countless resources could be preserved, and the opportunities to creatively change your favourite possessions are boundless," added MIT professor Stefanie Mueller.

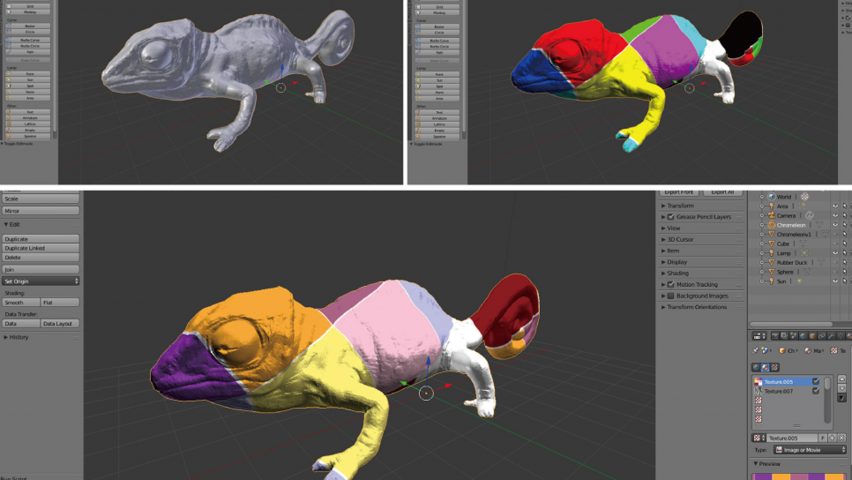

The CSAIL team invented both the ink and the user interface for processing designs and patterns onto objects.

The ink is actually a mixture of three photochromic dyes – cyan, magenta and yellow – that is evenly sprayed over an object.

Meanwhile, the digital interface allows users to apply a pattern of their choosing or creation onto a 3D model of the object.

Colours programmed using a projector and erased by UV

To merge the two, the user places the object in a box rigged with a projector, whose different wavelengths of light will eliminate different colours in the dye.

For instance, blue light is mostly absorbed by yellow dye, so the yellow dye is deactivated, leaving only magenta and cyan — a blue colour.

To erase the design, an ultraviolet light shines to return all the colours to their full saturation.

A video created by the lab shows them placing a shoe, a phone case, a toy car and a toy chameleon in the box to print them with patterns ranging from flames and florals to abstract geometries and high-resolution photography.

Financial backing for the project came from Ford Motor Company, which expressed interest in the potential benefits of the ink in the automotive industry.

"This ink could reduce the number of steps required for producing a multicolor part, or improve the durability of the colour from weathering or UV degradation," said Alper Kiziltas, technical specialist of sustainable and emerging materials at Ford Motor Co. "One day, we might even be able to personalise our vehicles on a whim."

The CSAIL team's next step will be to expand the colour palette possible with PhotoChromeleon by collaborating with material scientists.

MIT's CSAIL focuses on computing and artificial intelligence, with more than 900 researchers. Its previous projects include the soft robotic swimming fish SoFi and ColorMod, a direct precursor to PhotoChromeleon.