Anna Piasek makes bento-style boxes for takeaway food from moulded cellulose

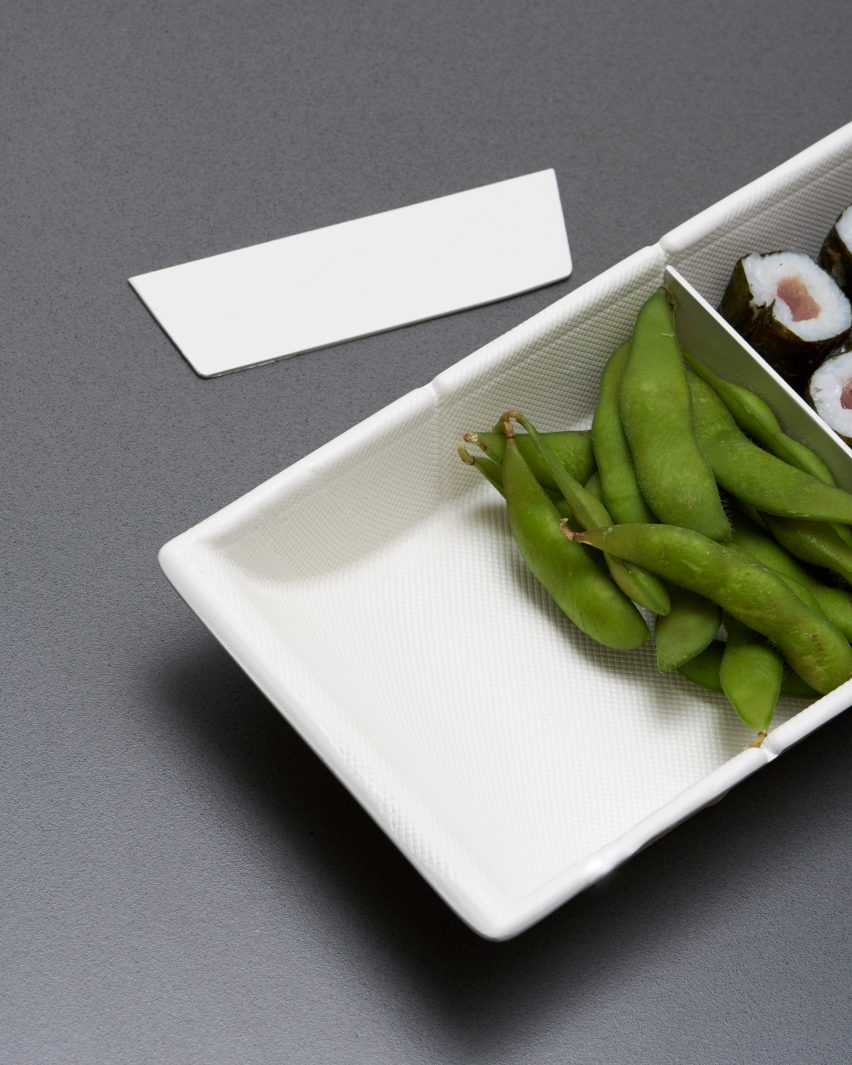

ÉCAL graduate Anna Piasek has created modular takeaway food packaging that can be divided like a bento box and composted after use.

The One Size, X Size cellulose packaging comes in three variants – a cylindrical cup to hold soup and other liquids, a rectangular box for one person and an octagonal one for sharing.

Like a traditional Japanese lunchbox, or bento, they can be sub-divided into smaller sections to accommodate multiple, separate dishes within the same space.

"An East Asian meal often consists of a variety of dishes in smaller portions or involves lots of side dishes," Piasek told Dezeen.

"When we have Japanese food in France, the amount of plastic containers used is insane because each one is put in a separate box."

So she decided to apply the bento principle to takeaway containers via small dividers that can be slotted into designated grooves, allowing for up to 10 possible configurations within a single container.

That means the smaller box for one person can house up to four different dishes, while the larger one has space for eight.

"When the lid is open, a round indent in the top is meant for pouring soy sauce," she added.

"When closed, this allows the cup to be embedded so it doesn't spill. Everything is designed to be stacked during transport for better stability – the one-person container is stacked on the sharing box and the miso soup container on top of that."

Piasek's containers are made from moulded cellulose, otherwise known as moulded fibre – a defined packaging material that primarily consists of recycled paper and water.

This is pressed into shape using a metal mould, and finally dried in an oven before a coating is added.

"The manufacturer I work with has filed a patent on a coating made 100 per cent from plant-based materials," explained the designer. "This makes the food safe and waterproof."

Moulded cellulose is perhaps most well-known for its use in egg cartons, but has been gaining more wide-spread popularity as a possible alternative to plastic packaging.

"The benefit is that it is infinitely recyclable or compostable," said Piasek. "It would take about two months to break down in an industrial composter. It could also be done at home but would take more time and maintenance."

Elsewhere, designers have developed plastic packaging alternatives using everything from animal byproducts to algae and food waste.

Photography is by Romain Roucoules.