RCA students develop SaltyCo sustainable fabrics using seawater plants

Students from the Royal College of Art have made fabrics from plants grown in seawater, providing a potential solution for the currently freshwater-intensive fashion and textile industries.

While cotton is notoriously water-hungry, requiring as much as 20,000 litres of freshwater to produce just a kilogram of the material, these fabrics are made from a salt-tolerant plant that thrives in seawater.

Insulating jacket liners, faux leather and clothing like t-shirts and trousers could all potentially be made with the fabrics.

The students – an interdisciplinary team from the Imperial College London and the Royal College of Art – came together to find a way to tackle the global overconsumption of freshwater.

This led to them to the idea of using salt-tolerant plants, and following promising early testing, they are now planning to launch a start-up named SaltyCo to bring their textile products to market.

"We were initially shocked by the vast quantities of resources that currently go into the fashion and wider textiles industry, specifically freshwater," SaltyCo's mechanical engineer Julian Ellis-Brown told Dezeen.

"We've been pushing our planet to the limit of its resources and are now starting to see the effects of wells drying up, lakes and reservoirs being replaced by deserts and more and more people suffering from water scarcity on a daily basis," he added.

While current industry efforts are mainly focused on using organic or recycled materials, Ellis-Brown said SaltyCo was looking ahead to the next challenge.

"For a long time now you have been able to buy organic, vegan and natural textiles," said Ellis-Brown.

"More recently we're also seeing the introduction of carbon neutrality as a standard. Now we're looking to what tomorrow's sustainable standard will be – freshwater-free fabrics."

"By creating a new calibre of what's necessary for an environmentally friendly textile, we hope to push brands and thought leaders to turn to these new materials," he added.

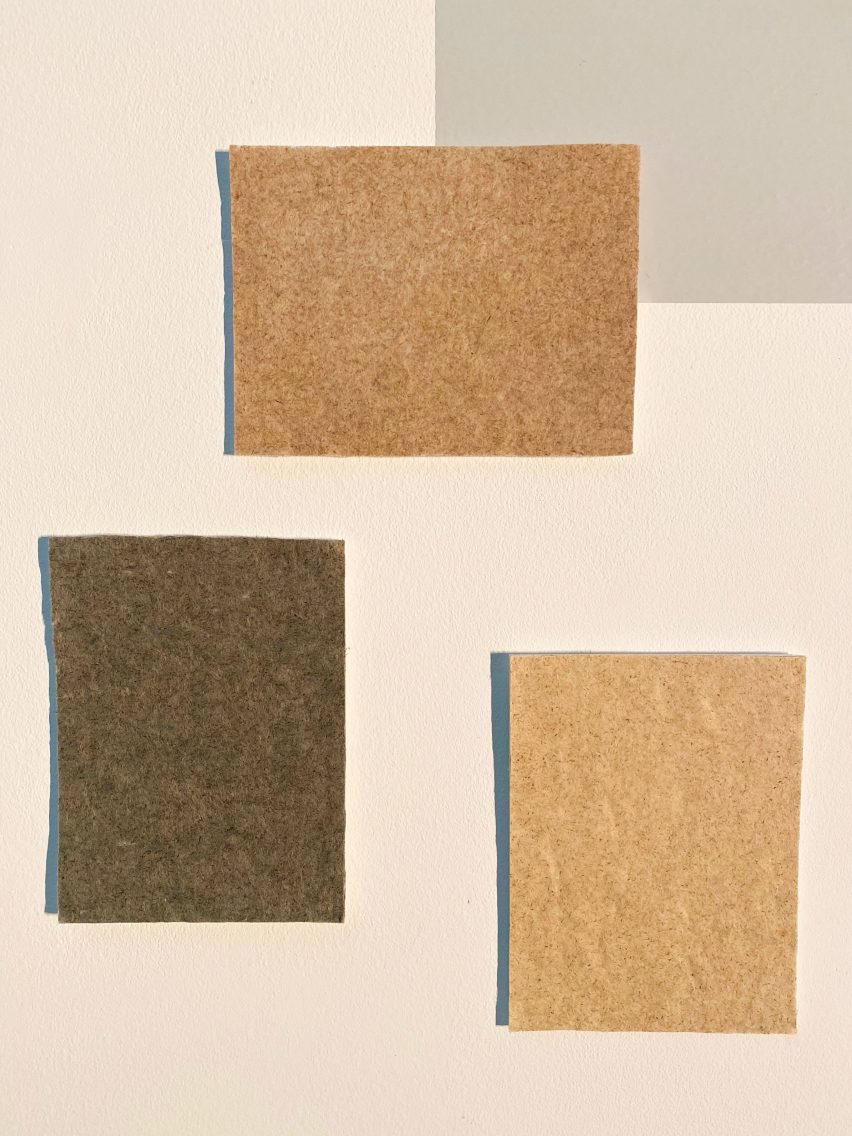

SaltyCo is developing three different textile products from their salt-tolerant plant, which, to protect their intellectual property, they cannot currently name.

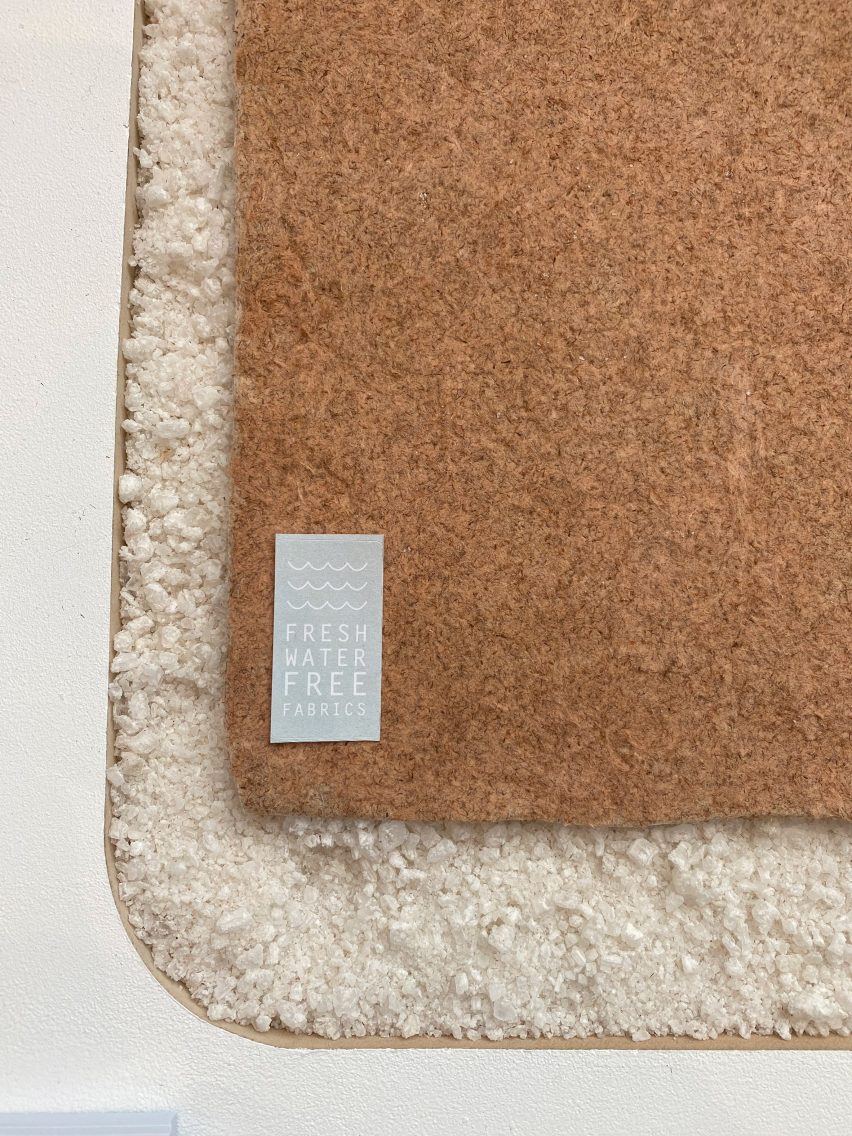

There is a woven fabric, a non-woven fabric and a technical stuffing.

The stuffing is the closest to being market-ready, and SaltyCo has already showcased it as part of a jacket. Ellis-Brown says it is warm, lightweight and hydrophobic, making it suitable for insulating jackets.

They have also showcased their non-woven fabric in a few forms, and see it being used for accessories or faux leathers.

The woven fabric requires the most further development and, if done right, it would have similar properties to linen or cotton.

SaltyCo is currently participating in Imperial Enterprise Lab's Venture Catalyst Challenge and hopes to launch the startup in the coming months.

Project credits:

Mechanical Engineer: Julian Ellis-Brown

Chemist: Finlay Duncan

Integrated designer: Antonia Jara

Business/design strategist: Neloufar Taheri