Austrian eyewear manufacturer Rolf has designed a collection of glasses that are 3D printed from a mixture of water and powdered castor beans.

The Tyrol-based brand's latest plant-based glasses collection, called Substance, is made from beans taken from castor trees. The range has been shortlisted in the product design category of Dezeen Awards 2020.

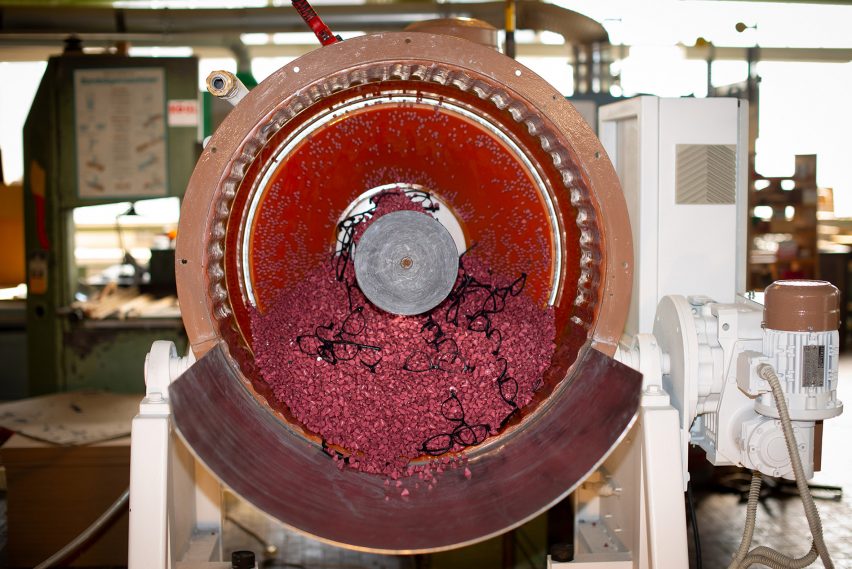

Rolf explained that as the peel of the bean is toxic, it removes this before grinding down the remaining contents into a powder. This is then 3D printed into frames for glasses, using mainly water as the binding material.

According to Rolf, the tall, fast-growing plants are grown in tropical climates without any genetic engineering, and they don't compete with food crops.

"Where a spruce or a beech will only grow a few centimetres taller every year, this remarkable plant will shoot up six meters in just six months, and it comes back every year," explained company founder Roland Wolf.

"This makes the new material more sustainable and kinder to the environment than ever – and the perfect foundation upon which to build a new collection of glasses called Substance and meet the current demand for more climate-considerate products."

The Substance glasses utilise Rolf's Flexlock hinge design, which involves no screws or spare parts. This grants the eyewear more flexibility than is already given from its pliable, plant-based material.

The Flexlock hinge can be 3D printed at the same time as the frame to enable the company to make all its glasses in one batch, minimising the amount of external suppliers needed.

The Substance collection offers 23 different frame designs in six colours, including black, grey, dark blue, khaki green and a bright pink hue.

The eyewear company, who is also known for its wooden glasses, manufactures all of its products by hand in Weißenbach, Tyrol. The brand was founded in 2009 and also offers glasses made from titanium and stone.

All of Rolf's glasses are made without any screws in order to rid the need for any maintenance.

London-based eyewear brand Kite also employed 3D-printing technologies for its KiteONE range of glasses, which it designed with Benjamin Hubert's agency Layer.

The brand takes 3D scans of customers' faces, measuring the distance between their pupils and head, their nose width and their ear positioning, which is then used to produce perfectly fitting frames.