Mineral Carbonation International aims "to lock a billion tonnes of CO2 into products by 2040"

Industrial carbon emissions can be captured and turned into useful materials on a vast scale, according to Sophia Hamblin Wang, chief operating officer of Mineral Carbonation International.

"We're trying to embed emissions into as much of our everyday life as possible," said Hamblin Wang. "We turn waste into new products. And we aim to do it in a way that makes money."

The Australian company turns CO2 into raw materials that can be put to a huge range of uses, according to Hamblin Wang.

"We're looking at carpet products, detergents, you name it. Anything that can have carbonates in it can be made from our synthetic carbonates."

Hamblin Wang joined Mineral Carbonation International (MCi) as its first employee in 2013 after the startup received funding to build a pilot plant in Newcastle, New South Wales.

It is now looking to scale up the technology to handle bigger volumes. "Our aim is to lock a billion tonnes of CO2 into usable products by 2040," said Hamblin Wang.

$5.9 trillion construction materials sector "needs to decarbonise"

MCi is initially focussing on producing construction materials, particularly new types of cement and drywall products to replace carbon-emitting Portland cement and gypsum-based materials.

"We know that cement is a heavily emitting industry, like four billion tonnes of CO2 per annum," Hamblin Wang said.

"The industry needs to decarbonise. Our silica products can displace ordinary Portland cement and we're working with giant cement majors on new products."

The construction materials sector is worth $5.9 trillion and, according to Hamblin Wang, there is "an explosion of interest" in low-carbon alternatives.

"Holy moly," she said. "It's been tumultuous in the past two years. We're working with some of the largest companies in the world on charting their path to zero carbon. We're helping them plan the decarbonisation of whole industries and whole facilities."

Slow natural processes can be compressed "into a matter of hours"

The Canberra-based company uses chemical processes that imitate natural weathering to remove carbon from factory emissions and sequester it in solid minerals.

"The earth naturally stores CO2 through a process called weathering, or mineral carbonation," said Hamblin Wang. "It's slower and less glamorous [than other carbon-capture methods] but it's one of the largest ways that the earth currently absorbs CO2."

Carbon dioxide dissolves in rainwater, forming weak carbonic acid. This slowly weathers rock, with the carbon combining with elements released from the rock by the weathering process to form new carbonate minerals.

"This happens over thousands or millions of years," Hamblin Wong explained. "What we've done is we've compressed that process into a matter of hours."

Instead of rock, MCi takes industrial waste such as steel slag, mine tailings and bottom ash from incinerators as well as quarried minerals such as serpentinites.

To make its raw materials, MCi bubbles CO2 through the industrial waste, approximating the way water-borne carbon interacts with rock in the natural weathering process. This creates new minerals such as magnesium carbonate, calcium carbonate and silica.

"The minerals absorb the CO2, which effectively gets turned from a gas into a solid," said Hamblin Wang. We then process it into myriad materials and products for everyday life."

MCi buys carbon dioxide from polluting industries

The process is exothermic, meaning the chemical reaction creates heat, so does not involve vast amounts of power.

However, crushing the industrial waste in the first place is energy-intensive. MCi uses renewable energy "where we can," says Hamblin Wang, but future plants will need to switch entirely to renewables if they are to offer a viable contribution to global decarbonisation efforts.

MCi buys its carbon dioxide from polluting industries that have fitted scrubbers to their chimneys to capture the gas before it reaches the atmosphere.

"Right now we take our emissions from an ammonium nitrate factory, which captures its emissions every day," said Hamblin Wang.

"We can carbonate raw flue gas," she said, meaning that MCi is able to purchase emissions containing low percentages of carbon that have few other commercial uses. "We can take it [in concentrations] as low as 15 per cent [CO2]."

Steel industry doesn't have "viable decarbonisation options"

Carbon scrubbing, also known as post-combustion capture, is a long-touted technology that could theoretically remove greenhouse gases from factory flues, preventing them from reaching the atmosphere.

The drawbacks are the cost of retrofitting plants, the fact that it could encourage polluting industries to continue burning fossil fuels, and the issue of efficiency: for a factory to be carbon neutral, one hundred per cent of its greenhouse gas emissions need to be captured.

However, Hamblin Wang argues that some key industries will struggle to decarbonise due to their high-intensity energy needs, which can currently only be provided by burning and processing fossil fuels.

"The problem is that the steel and cement industries don't currently have viable decarbonisation options," said Hamblin Wang.

"The kind of heat that you need in order to make steel, for instance, you just can't get through electrification. These thermal processes don't have pathways [to net-zero]. You will still need metallurgical coal in order to create steel."

Company aims to make carbon emissions "not only inert but profitable too"

In addition, minerals such as nickel, lithium, cobalt and copper that are vital to making batteries, among other things, all involve carbon-intensive processing.

"There are technologies being developed like hydrogen, but it's still looking like it's 20-plus years in the future," said Hamblin Wang. "If we're looking at a gradient to get to net-zero, those industries are the ones that really need help."

"So our real mission is to help with this transition to capturing the emissions, say, of a steel plant's stack pipe and then rendering those emissions not only inert but profitable too."

Hamblin Wang sees mineral carbonisation as one of several emerging approaches that need to scale up and work together to tackle climate change.

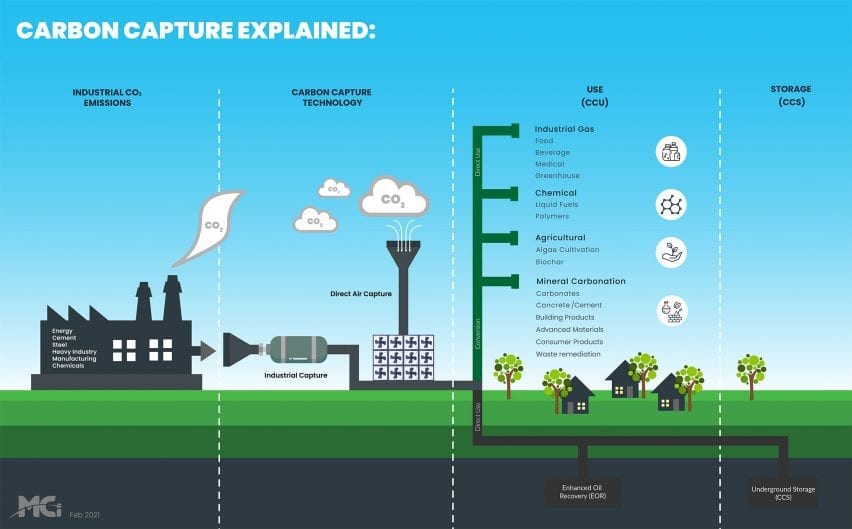

These include: dramatically reducing new greenhouse gas emissions; removing anthropogenic CO2 from the atmosphere; and storing or utilising that captured carbon on earth.

MCi is "trying to embrace the circular economy"

Direct air capture technologies such as that developed by Climeworks could one day scale up to significantly reduce atmospheric CO2 but the problem, according to Hamblin Wang, is where to put all the captured carbon.

"Even if we captured all of the CO2 emissions from all of our industry right now, and we suck CO2 out of the atmosphere in the volumes that required, we currently don't have enough places to put the CO2," she said.

Carbon capture and storage (CCS), which involves burying carbon, is "a linear business model where they pump it underground and it costs money and you monitor it forever," said Hamblin Wang.

The alternative is carbon capture and utilisation (CCU), whereby the carbon is put to use.

"We're trying to embrace the circular economy where you turn your waste from your industry and your waste gas into valuable products that can be used in the economy," she said.

"Those products also displace products that would need to be mined or that may have high carbon intensity embedded in them. So the benefit is twofold."

Carbon revolution

This article is part of Dezeen's carbon revolution series, which explores how this miracle material could be removed from the atmosphere and put to use on earth. Read all the content at: www.dezeen.com/carbon.

The sky photograph used in the carbon revolution graphic is by Taylor van Riper via Unsplash.