Berlin startup Made of Air has developed a bioplastic made of forest and farm waste that sequesters carbon and can be used for everything from furniture to building facades.

The recyclable material is 90 per cent carbon and stores around two tonnes of carbon dioxide equivalent (CO2e) for every tonne of plastic.

By 2050, Made of Air hopes to be storing up to a gigatonne of CO2e a year in the material, which is also called Made of Air.

Company aims to "help reverse climate change"

"While we are a materials company, really in our heart we are a climate company and that's the reason for our existence," the company's chief commercial officer Neema Shams told Dezeen. "We're aiming to help reverse climate change."

Since the material stores more CO2 from the atmosphere than it emits throughout its lifecycle, Made of Air is a carbon-negative material, Shams said.

"We see carbon-negative as what biodegradable was 10 years ago," he explained. "Back then, no one knew what it was, no one knew why it mattered. And now it's pretty ubiquitous."

Made of Air was founded in 2016 by architects Allison Dring and Daniel Schwaag, who previously collaborated to create a pollutant-absorbing cladding called Prosolve370e.

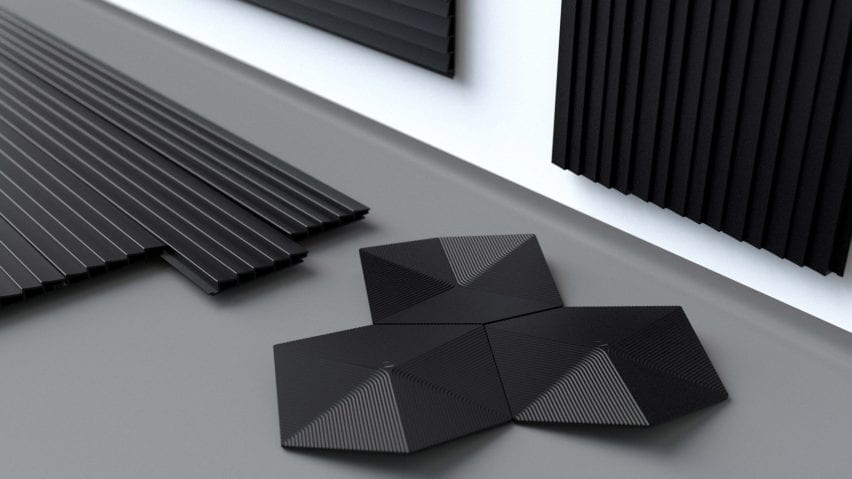

The new company has identified five sectors where its bioplastic can be used. These are building facades, furniture, interiors, transport and urban infrastructure.

The material has recently been used to create a pair of limited-edition sunglasses in collaboration with H&M.

The company is also in talks with a US furniture maker about creating a "carbon-negative chair" and with automotive manufacturers about creating car parts.

In April, the thermoplastic was installed on a building for the first time. An Audi dealership in Munich was clad in seven tonnes of hexagonal panels the company calls HexChar.

The material is made of biochar

According to Shams, a lifecycle analysis has shown that the dealership's cladding stores 14 tonnes of carbon.

Over the next year, the company is ramping up its production capacity by 100 times to sequester 2,000 tonnes of CO2e each year.

Made of Air is a non-toxic bioplastic made from biochar. This charcoal-like material is almost pure carbon and is made by burning biomass such as forestry offcuts and secondary agricultural materials without oxygen.

Biochar has been produced for centuries and is increasingly being used as a fertiliser as well as a way of sequestering carbon in the soil.

Made of Air mixes biochar with a binder made from sugar cane to create a material that can be melted and moulded like a regular thermoplastic.

"We have a proprietary process that takes the biochar, puts it through a series of steps and combines it with bioplastics to create granules," Shams said.

The granules can then be used in traditional plastic-forming processes such as injection moulding and can be processed using the same machinery as regular plastic.

To make its biochar, Made of Air sources waste from forestry and agriculture businesses based in the countryside around Berlin.

The biomass is then placed in a special furnace, where it is baked in a controlled, oxygen-free environment as part of a process called pyrolysis.

Without the presence of oxygen, the carbon in the biomass cannot form carbon dioxide during combustion, meaning there are no greenhouse gas emissions. Instead, the carbon remains and forms biochar.

The porous, carbon-rich material is highly effective at storing carbon. Unlike decaying biomass, which quickly releases its carbon back into the atmosphere, biochar remains stable for hundreds or even thousands of years.

"With biochar, if you just left it on the ground and came back a thousand years later, it would look exactly the same," Shams said. "Only if you were to burn it would that carbon be re-released."

Made of Air is one of a number of companies that view atmospheric carbon as an untapped resource.

Swiss company Climeworks, for example, is building direct air capture machines to create carbon it can sell, while Seattle start-up Nori is building an online marketplace that incentivises people to capture and trade atmospheric carbon. The process by which this captured carbon is then turned into useful products is called carbon capture and utilisation (CCU).

"What if everything we're surrounded with was removing emissions instead of releasing them?" said Shams. "Climate change is really a material problem in that there's too much carbon in the atmosphere. So how come we can't turn that into our biggest resource?"

Made of Air's biochar plastic is cheaper than regular bioplastics but still more expensive than petroleum-based materials.

Material prices don't reflect "cost to the planet"

Ultimately, Shams believes that government intervention in the form of a carbon tax is needed in order to help products made from captured CO2 replace fossil plastics.

"In the wider capitalist system that we live in, everything needs to be cheap and widely available," he said. "The price of materials doesn't take into account their cost to the planet or to people."

"I think putting a value on the emissions associated with their production and their damage to the environment will be the most useful catalysts not only for us but for the wider sustainable materials space."

Carbon revolution

This article is part of Dezeen's carbon revolution series, which explores how this miracle material could be removed from the atmosphere and put to use on earth. Read all the content at: www.dezeen.com/carbon.

The sky photograph used in the carbon revolution graphic is by Taylor van Riper via Unsplash.