Lego develops recycled bricks made from discarded bottles

Toy brand Lego has created its first prototype bricks using recycled PET plastic from discarded bottles.

Created as part of the Danish company's drive to make all of its products from sustainable materials by 2030, the brick prototypes were created from recycled polyethylene terephthalate (rPET), a common thermoplastic used for products such as bottles and clothing.

The prototype, which has been developed over the past three years, was made from used plastic bottles acquired from suppliers in the United States.

A one-litre plastic bottle supplies enough raw material for around 10 2x4 Lego bricks.

Lego trialled over 250 formulations of the recycled plastic to create a brick that complies with the company's quality, safety and play requirements.

Its "clutch power" – the ability to snap onto other pieces of Lego – means that it is compatible with Lego's standard bricks.

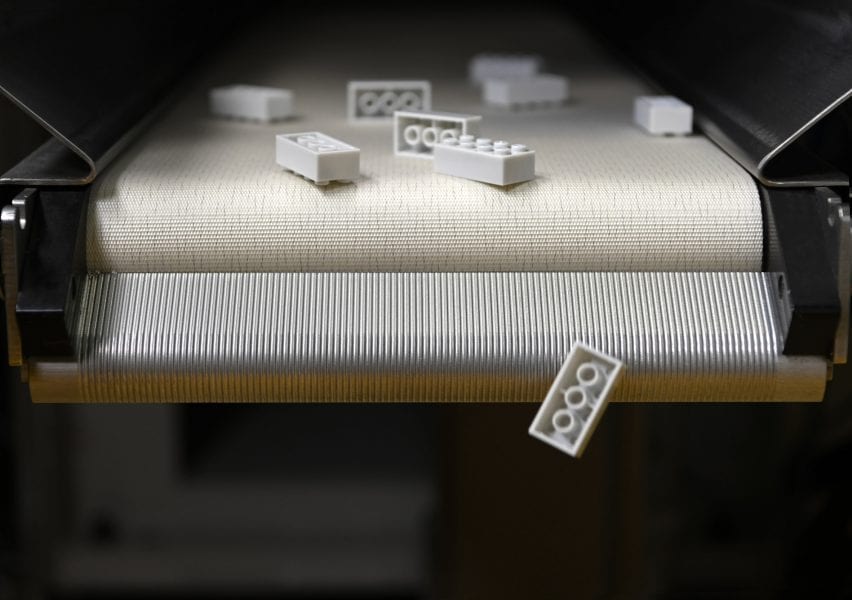

Lego now plans to rigorously test and develop the prototype brick before assessing whether to move the rPET into production.

Tests will determine whether the patent-pending material formulation is strong and durable enough for Lego bricks.

"We need to work on how we colour the material consistently and look into the different shapes it can be moulded into," Lego told Dezeen. "Then we will be in a position to assess whether to move into pilot or trial production."

"Any new materials we use must live up to the high quality and safety standards as those we apply to our existing products – this includes the product durability," the brand said.

Founded in 1932 by Ole Kirk Kristiansen, Lego has become one of the world's leading toy brands. This is in part thanks to the iconic brick's durability.

Since 1963, the majority of the billions of Lego bricks produced each year have been made from a plastic called acrylonitrile butadiene styrene (ABS).

Finding a material as durable as the traditional ABS bricks has proved to be difficult for the toymaker.

"For us, the challenge comes from needing materials that can be moulded to the accuracy of a hair width to ensure bricks produced today fit with those made over 60 years ago, while being durable and safe enough to be handled by children day-in, day-out," said Lego.

"Lego bricks are designed to be safe and durable enough to be passed from generation to generation rather than being thrown away. Despite this, we are committed to making our products from more sustainable materials in the future," it continued.

"To do so, we need to invent entirely new materials, as existing sustainable materials do not meet our safety and quality requirements."

The bricks were created as part of the toy company's wider strategy to make all core Lego products from sustainable materials by 2030. Its sustainability goals include developing bricks from bioplastic and generating little or no waste. Last year, the company announced it will begin removing single-use plastic from its boxes.

Lego defines a sustainable material as something that is "responsibly produced, using renewable or recycled resources, generating little or no waste, use sustainable chemistry and be fully recyclable at the end of its life."

In 2018, the company launched sustainable bricks made from sugar cane. Earlier this year it released a set of flowers to help people "switch off and relax" at home, which included parts made from the bioplastic components.

"We're committed to playing our part in building a sustainable future for generations of children," said Lego.

"We want our products to have a positive impact on the planet, not just with the play they inspire, but also with the materials we use."