Digital twins are "big driver" towards net-zero cities say experts

Digital twins of buildings and cities could become an essential tool in the battle against climate change, according to technology experts.

These virtual replicas – computer models that use live data to create simulations of real-world objects and systems – can reduce the energy consumption of buildings in operation, proponents claim.

They do this by analysing a range of data sources, from heating and air conditioning systems to employee schedules and local traffic flow patterns. By identifying inefficiencies in these systems, digital twins can propose more energy-efficient approaches.

Digital twins can also lower the carbon footprint of new buildings and structures by optimising the energy efficiency of the construction process, and by tracking and controlling the supply chains of materials and products to reduce embodied carbon.

"In the cities, buildings and infrastructure world, I think the big driver for digital-twin adoption is around decarbonisation," said Michael Jansen, founder and CEO of digital twin software company CityZenith.

"Digital twins can help at multiple stages in the process of making a building go from carbon-positive to carbon-neutral," he told Dezeen.

In order to ensure global warming remains within 1.5 degrees Celsius of pre-industrial levels, the global economy needs to become net-zero by 2050, according to the 2015 Paris Agreement on the climate. This means ending all greenhouse gas emissions or negating unavoidable emissions with offsets that capture carbon from the atmosphere.

UK government invests in digital twins

Software developers and tech entrepreneurs predict this will lead to a huge uptake in digital twin technology, as governments and commercial organisations face increasing pressure to reduce their contributions to climate change.

The UK government is already investing. With its Centre for Digital Built Britain, a collaboration with the University of Cambridge, it has launched a National Digital Twin programme to build an eco-system that connects digital twins across businesses, allowing them to more easily share data.

The Centre for Digital Built Britain, supported by the UK government, is building an eco-system of connected digital twins

Sarah Hayes, outreach lead for the programme, believes digital twin technology could play a crucial role in helping cities achieve net-zero carbon emissions.

"[Digital twins] can help us understand the impact of decisions and actions," she told Dezeen.

"If we'd had digital twins 20 or 30 years ago, would we be facing such a climate crisis now?" she said. "Would we have invested in oil and gas in the way we did, if we'd had all the information about the consequences back then?"

"It's about putting that information together, to be able to better understand the big picture; I think digital twins is the route to doing that."

Reducing energy use and carbon emissions

A study published in September 2020 predicted the market for digital twins to increase from $3.1 billion to $48.2 billion by 2026.

The technology is most commonly used in manufacturing, healthcare and logistics. For example, BMW and Tesla have integrated digital twins into vehicle development, medical researchers are using it to simulate the impacts of different treatments, and courier service DHL is using it to optimise operations in its warehouses.

Architects and designers are also experimenting with digital twins. The technology is being used to test the performance of the world's first 3D-printed bridge, so that the data can be used for future iterations of the design, while Foster + Partners has been using a robot dog to source data for a digital twin of a building under construction.

A recent report from professional services company EY found that digital twins can help to reduce the greenhouse gas emissions and carbon footprint of an existing building by up to 50 per cent, alongside cost savings of up to 35 per cent.

The report refers to case studies that include Nanyang Technological University in Singapore, which tested the use of digital twins to reduce energy use, water consumption, carbon emissions and waste across its campus of over 200 buildings.

Using data from a five-year period, the technology was able to suggest changes to building operations, resulting in a 31 per cent saving in energy use and a carbon emissions reduction of 9.6 kilotons.

Smart building management

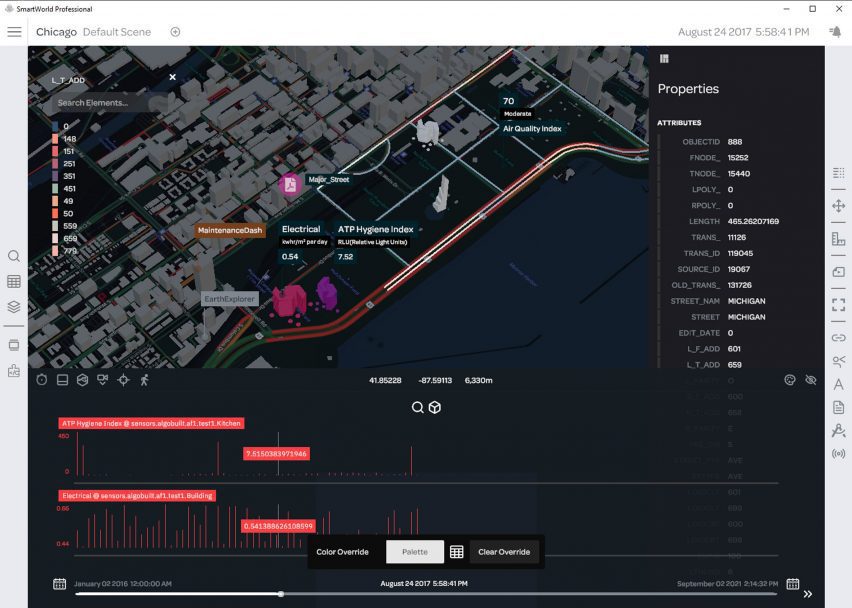

CityZenith's SmartWorldPro is one of various digital twin software packages to offer opportunities for carbon reduction through efficient building management.

Developed specifically for the construction and real-estate sector, it can be used to manage the operation of both existing buildings and projects under construction.

As part of a recent campaign called Clean Cities Clean Future, CityZenith is now offering its software to a selection of cities at no charge, with the promise that it can help them to reach net zero by 2050.

A pilot project will see the technology used to cut operating costs and carbon emissions at Brooklyn Navy Yard in New York.

"Digital twin technology could play a central part in decarbonising our built environment," wrote Jansen in a recent article for the World Economic Forum.

"Building owners, city planners and governments can use digital twins to track, manage and minimise emissions from both new and old buildings, as well as during construction," he said. "[They] can also predict traffic flow, or control individual room temperature."

Scottish company Integrated Environmental Solutions (IES), another digital twin provider specialising in the built environment, has also proven that this technology can be used to reduce the carbon footprint of a wider area.

A digital twin built from IES's Virtual Environment software was used to optimise local wind power on Eday, one of the Orkney islands, allowing an entire community to reduce its energy requirements by 76 per cent in a payback of less than six years. The community hopes the changes will allow them to eliminate fossil fuel consumption on the island completely.

Traceability as a service

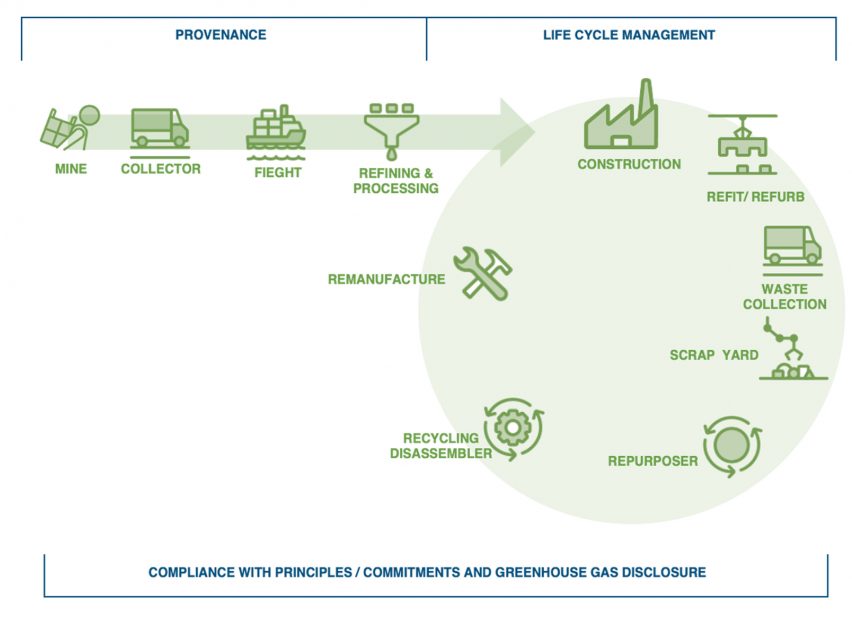

Decarbonising the supply chains of materials and products used in construction is a more difficult process, as it can involve sourcing data from a global network of manufacturers and suppliers, some of whom may not want to share their data.

One company taking on this challenge is Circulor, which has built up a large network of sources that allow it to uncover detailed information about supply chains. It offers this to a range of companies in a business model it calls "traceability-as-a-service".

Circulor has worked with manufacturers such as car brands Volvo and Mercedes, aerospace company Boeing and EV battery manufacturer CATL to bring transparency and efficiency to their production, but is now moving into the construction sector.

"I think we're going to start seeing more specification for sustainable construction, and to do that, you need this traceability that we're talking about here," said Douglas Johnson-Poensgen, CEO and co-founder of Circulor.

"People will want to know whether their green steel is really green," he told Dezeen.

Buildings with digital passports

Technology is fundamental to Circulor's operation. The company uses digital twins in parallel with blockchain technology, as a way of tracking the source of materials without any possibility of corruption.

According to Johnson-Poensgen, the process is inherently more complicated than a "bag and tag" system, where materials are simply traced from start to finish. Many materials go through several transformations in the process, so tracing these complex networks is only possible with the use of digital twins.

"The challenge is far greater than tracking food or a diamond," he said, " because the digital representation of the commodity has to be able to cope with each of its transformation steps."

"But the idea is that you track the most polluting components, so that you're confident that they are as sustainably produced as they can be," he said. "Then you create a ‘digital passport' for a building, which includes all the ingredients that went into manufacturing each of its components."

"You've then got something you can use as a basis to, for example, refurbish that building in a more sustainable way."