The sun offers an endless source of energy but solar technology is being held back by manufacturing limitations, says Dutch scientist and professor Wim C Sinke in this interview.

Speaking to Dezeen as part of our Solar Revolution series, Sinke said that the embodied carbon involved in producing solar products is currently a barrier to scaling up the technology.

"It is a process that requires a lot of energy"

"There is no limitation [to solar power] if you do everything perfectly – if you use the right materials and introduce circular technology," he said.

"But we're not successful in that, so there are limitations, especially if we want to expand the sector rapidly."

Until his retirement in May 2022, Sinke was principal scientist at Dutch research organisation TNO and a professor of photovoltaic energy conversion at the University of Amsterdam.

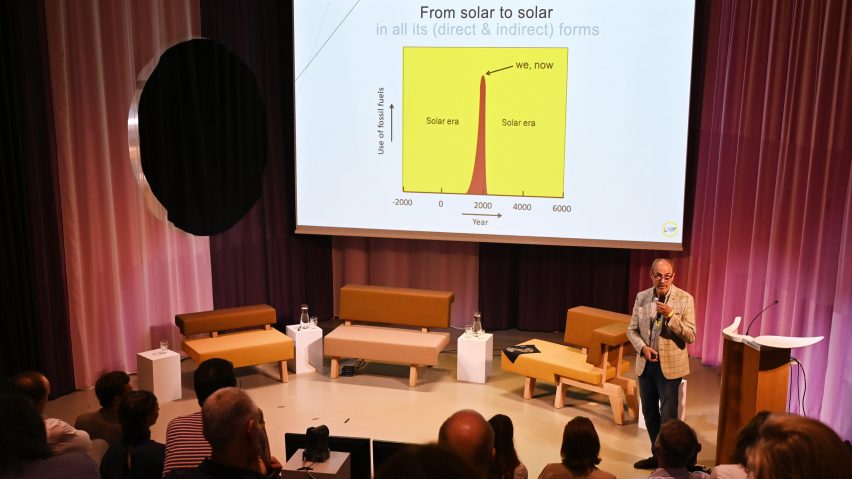

He spoke to Dezeen following a presentation during The Solar Seminar, a solar-design conference that took place at Het Nieuwe Instituut in Rotterdam on 9 September as part of The Solar Biennale.

The scientist said that the energy and materials required for manufacturing solar cells is one of the biggest obstacles in the ambition to increase production of solar energy.

The majority of photovoltaic cells are made from silicon – a material that is abundant in the Earth's crust, but which has to be highly processed for this purpose.

"It is a process that requires a lot of energy, and if that energy is not renewable then there are carbon emissions associated with that," Sinke explained.

"The climate payback time of a solar module may only be a few years, but if you expand rapidly then that value can still be significant."

Switch to circular economy necessary

Another issue, according to Sinke, is that many of the other materials required for manufacturing solar products are only available in limited quantities.

"For instance, the high-quality glass that is used for solar modules is not available in the quantities we would need for the sector to rapidly expand immediately," he said.

Sinke believes a switch to a circular economy – which would see the components of old solar products recycled at the end of their lifecycle – is necessary for the solar energy sector to grow.

One way of achieving this shift, he suggests, is to find a way to replace the silver components in photovoltaic panels – which help to optimise energy generation – with aluminium.

Although a large amount of energy is required to manufacture aluminium, it is the easiest metal to recycle.

"If we want to build an industry sector producing solar modules in a sustainable way, we need the whole value chain, from raw materials up to the complete systems, to work in a circular manner," Sinke said.

"We cannot afford to wait decades"

Sinke has spent decades researching the field of photovoltaic solar energy and developing solutions. He was awarded a knighthood in 2015 for his achievements in the field.

He believes a solar revolution is possible, but only if the lifecycle of solar products is urgently rethought at a systemic level.

"It's not too late," he said. "We can solve the problems that we're facing, but we have to make a huge, focused effort to make that happen."

"We cannot afford to wait decades," he continued. "We can build manufacturing capacity in a few years, but society needs to be convinced of the importance of that."

The photography is by Lindy Hengst.

Solar Revolution

This article is part of Dezeen's Solar Revolution series, which explores the varied and exciting possible uses of solar energy and how humans can fully harness the incredible power of the sun.