3D-printed walls added to abandoned wooden home to create Traditional House of the Future

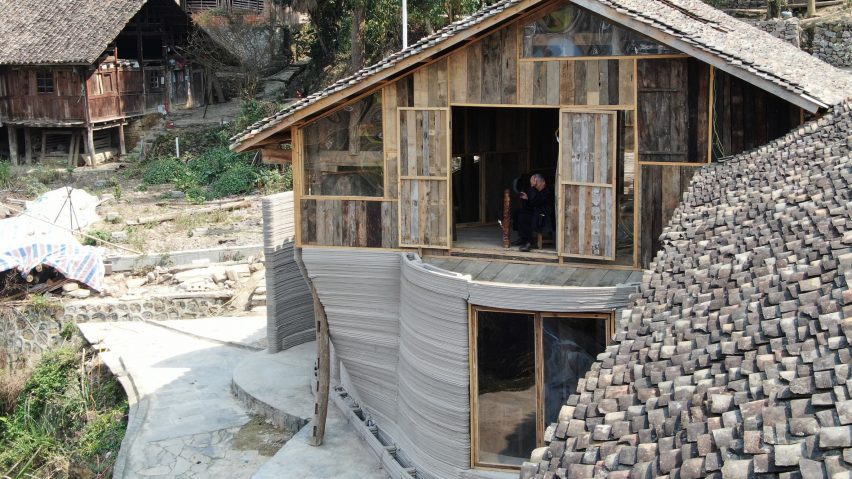

University of Hong Kong professors John Lin and Lidia Ratoi have combined an abandoned traditional wooden house in China with a 3D-printed structure.

Named Traditional House of the Future, the prototype project is part of a government plan in Nanlong Village in southwest China to renovate hundreds of old wooden houses that have become dilapidated.

The original house was scanned by Lin and Ratoi, before being dismantled and then expanded and supported on 3D-printed walls.

The 3D-printed exterior walls expand the space of the original house, while additional dividing walls were added to create an entrance courtyard kitchen and bathrooms.

Following the construction of the 3D-printed walls, the wooden structure and tiled roof were added back to the house.

"The project questions how technology can act as a social potentiator and become a means to strengthen local and cultural building practices," the professors said.

"Considering the existing built fabric as a 'new nature', which cannot be altered and therefore requires adaptation, the process touches upon key areas of sustainability: social, technological, and cultural."

The design of the house was based on research by Lin and Sony Devabhaktuni from the University of Hong Kong that investigated innovative renovations of vernacular houses carried out ad hoc by builders in remote locations in rural China.

Their research project, which won the RIBA President's Medal for Research, aimed to present a fresh perspective on these ancient dwellings. It treated them as continuous flexible design modifications that could respond to changing lifestyle, rather than just preserving a cultural heritage.

Changing lifestyles in rural China is requiring new configurations for traditional Chinese wooden houses as the lack of flexible spaces to incorporate modern amenities have resulted in them often being abandoned.

Adding 3D-printed walls aimed to allow locals to recycle these old houses and reassemble them into new houses.

"It encapsulates the realities of a rapidly changing lifestyle, at the intersection between traditional and modern, neither rural nor urban," said Lin.

3D-printed homes are gaining attention for their resilience and modular construction method in harsh and remote locations. Danish studio BIG and 3D-construction firm ICON are designing a desert campground and housing project in Marfa, Texas, as well as Wolf Ranch in Georgetown Texas, a 100-home neighbourhood that will be the largest 3D-printed community in the world.

The photography is courtesy of Lidia Ratoi and John Lin.

Project credits:

On-site 3D printing: Professor Xu Weiguo / Tsinghua University

Woodworking: Liu Anhai with local carpenters

Project leader: Yi Sun

Project team: Bo Lee Lau (Team leader in Spring 2022), Chau Ka Yee, Priscilla Chi Kar Yee, Osten Chan Chun Ngok, Wang Mengyan, Jenny Hsiao and Year 2 students HKU

On-site team: Sun Chengwei, Zhao Xiayu, Hu Hanyang

Documentation: Deng Rui Rui, Motong Yang, Liu Chang