New Delft Blue archways wrapped in 3,000 unique 3D-printed ceramics tiles

Architecture practice Studio RAP has combined algorithmic design and 3D printing to create a pair of archways informed by Delft Blue porcelain at the PoortMeesters housing in the Netherlands.

Named New Delft Blue, the archways were designed to frame entrances to a courtyard garden at the centre of the housing development in Delft designed by The Hague-based VY Architects.

They were constructed using 3,000 unique tiles that were 3D-printed and arranged in a pattern determined by an algorithm created by Studio RAP.

Informed by the colour of traditional Delft Blue porcelain, which gives the project its name, the tiled portals were designed to reference the city's history and demonstrate current technological advances.

"The project embodies the unique identity of Delft in a contemporary way, by referring to its history," said Studio RAP.

"It's algorithmically designed, nature-inspired patterns in blue refer to Delft of today as the city of knowledge by using cutting-edge design and 3D-printing technology."

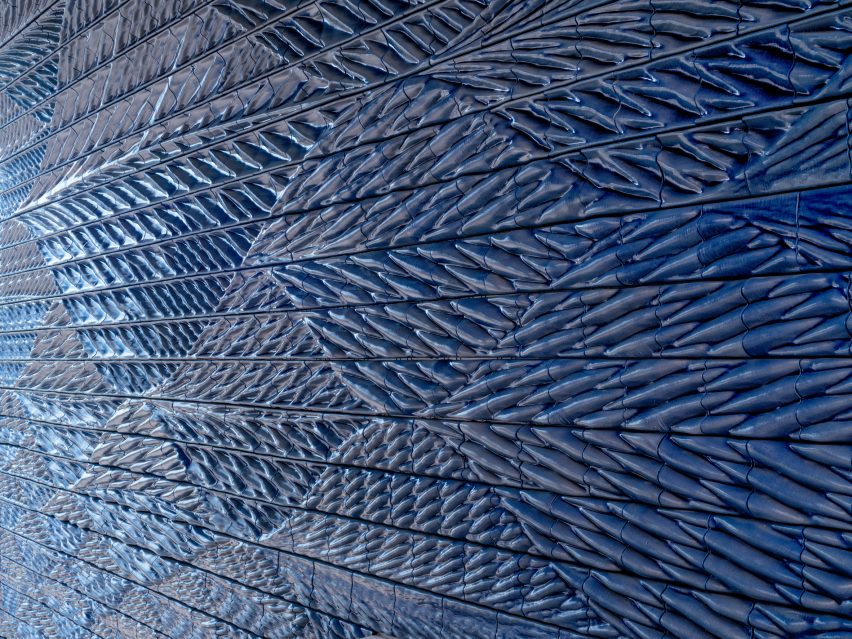

The patterns on each of the archways, which cover concrete stairs, were designed to have leaf-like forms based on the patterns of Delft Blue porcelain.

In total 3,000 unique tiles that measure around 40 centimetres by 30 centimetres were 3D-printed by Studio RAP and coloured using a transparent blue glaze.

"After studying different nature-inspired patterns on Delft Blue plates, we developed an algorithm that generated a leaf pattern that grows from one side to the other side that guides people over the staircase between two different public spaces," explained Studio RAP co-founder Lucas ter Hall.

"We strived to design a pattern that's not too figurative and not to abstract, this field of tension makes the design to our opinion more timeless," he continued.

"All tiles are unique, all leaves are unique, every time you walk through the gates one experiences something different."

Along with the nature and patterns of Delft Blue porcelain, the shapes of the tiles were determined by the constraints of 3D printing.

"Together with the manufacturing constraints of the 3D printing technology – such as maximum overhang, width, height and depth, material behaviour, shrinkage and internal support structure – the tiles were formed," explained Ter Hall.

"This iterative process between stylistic and fabrication variables made this gate a thorough masterpiece showcasing digital craftsmanship in optima forma!"

According to the studio, the capacities of 3D printing allowed it to have full control over the complex design.

"To have the possibility to 3D print ceramics in-house gives us superpowers as architects," continued Ter Hall. "We establish a complete digital workflow from design to realisation, maximising our design ambition and guarantee high quality architectural designs."

"We gain more control over the final design, time planning and building costs, what brought us in a unique kind of 'master builder' role," he added.

Studio RAP hopes that the gateways will enliven and enhance the residential development and be embraced by the residents.

"With every project we design, we strive to make the world more exciting and diverse," said Ter Hall. "New Delft Blue is such statement to enrich the world with a new architectural language, one that breaks barriers by innovating the way the world is envisioned, built, and experienced."

"New Delft Blue gives the building a unique identity and we hope that the residents will embrace it," he continued.

Rotterdam-based Studio RAP was founded by Ter Hall along with Wessel van Beerendonk and Léon Spikker. It previously created the "first robotically fabricated building in the Netherlands".

The photography is by Riccardo De Vecchi and film by Oculus Film.

Project credits:

Client: BPD (Bouwfonds Property Development), Ballast Nedam Development, Ballast Nedam Bouw West

Architect New Delft Blue: Studio RAP

Contractor and 3D ceramic printing: Studio RAP

Glazing and firing: Koninklijke Tichelaar

Architect PoortMeesters: VY Architects