BioProsthesis uses human hair to create prosthetic nipples for breast cancer patients

Central Saint Martins graduate Arianna Pezzano has developed a way to make nipple prosthetics from keratin extracted from hair lost during chemotherapy, to help breast cancer patients "regain a sense of wholeness".

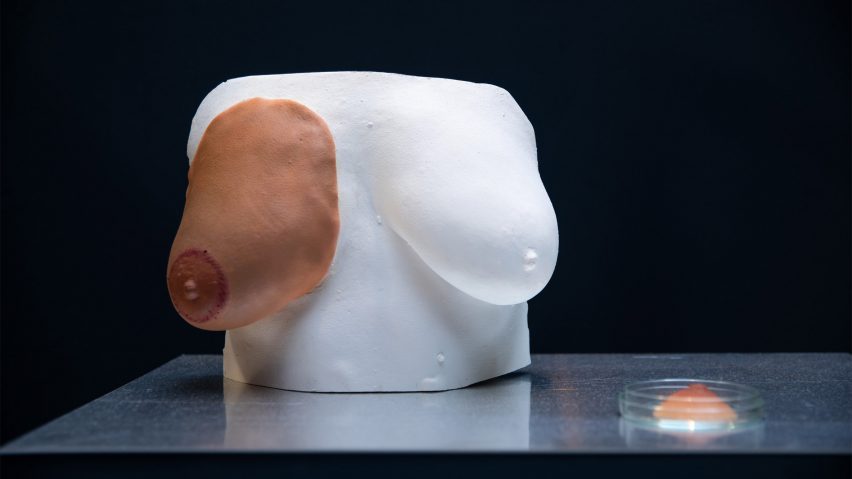

Created as her MA Material Futures thesis, Pezzano's BioProsthesis prototype project creates tailor-made nipples developed from the patient's own cells and painted to match their skin tone.

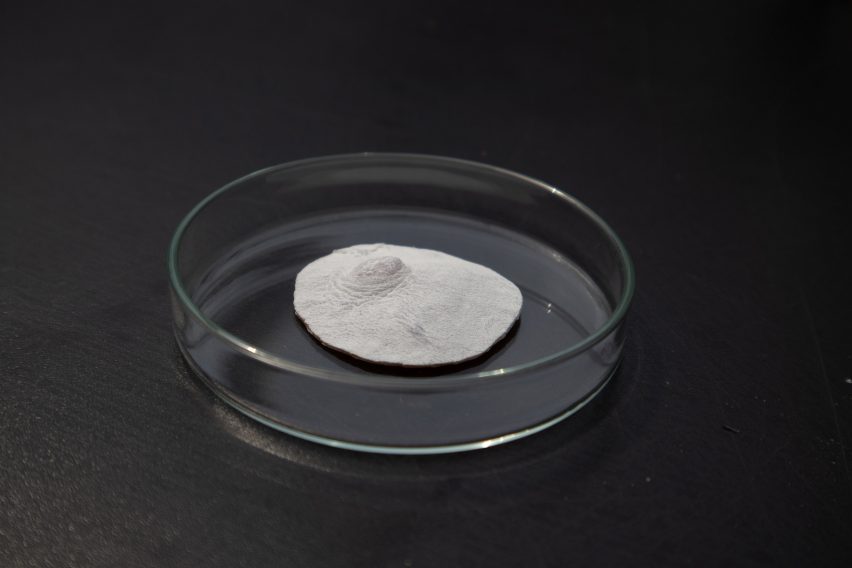

In the project, hair lost during chemotherapy is collected and a chemical process is used to extract keratin, a fibrous protein.

Pezzano then makes a cast of the patient's breast to create an aluminium mould. The mould is placed in an electrospinning machine with the keratin solution, which is spun to form a lightweight prosthetic nipple.

According to Pezzano, electrospun fibres are widely used in medical applications, such as tissue engineering, due to their high surface-area-to-volume ratio, porosity and structural alignment.

In using keratin sourced from the patient, the designer aimed to make biocompatible prostheses that give the patient a whole and complete feeling.

"This process enables the patient to regain a sense of wholeness, with the keratin used in the prosthesis serving as a replacement for the loss of their breast, symbolically reuniting the first loss of hair with the body in the form of a prosthesis and facilitating the acceptance process and psychological healing," Pezzano told Dezeen.

"Taking advantage of keratin biocompatibility allows me to achieve a circularity process – taking from our body to give back to our body, helping a healing process," she added.

The human-sourced keratin also negates the need to source the protein from animals or other bioresources.

"In many cases, the run for bio-alternatives has led to the exploitation of other living species, which can have devastating consequences for ecosystems and the environment," Pezzano explained.

"Sourcing materials from our body offers significant advantages in terms of scalability and accessibility – the global population continues to grow and represents a potentially vast resource," she added.

The designer began developing BioProsthesis by focusing just on the nipple rather than the whole breast, as she found there is currently less research development in nipple reconstruction.

"As emerged from interviews with patients, the missing nipple has the biggest and most immediate aesthetical impact and is often what bothers the patient the most," said Pezzano.

"Secondly, reconstruction of the breast has been explored more deeply and there are multiple solutions available, including silicone prosthesis and fat injection, while reconstruction of the nipple often takes second place."

Pezzano hopes BioProsthesis, which can be made in a variety of skin tones, can be developed into a whole breast and nipple prosthesis.

She explained that 3D printing would be used to make the breast prosthesis look and feel as real as possible.

"The partial or total breast-filling prosthesis would be manufactured with 3D printing technology using a keratin-based filament, modelled following a biomimetic approach that considers the morphology of a real breast regarding its internal structure to obtain authentic mobility and feel," Pezzano explained.

The nipple prosthetics are not yet tested against medical standards and regulations, but the designer hopes the prototype design will be developed for surgical use with the help of medical professionals.

"While this represents an important initial step, the ultimate goal would be to develop a medical-grade prosthetic that can be implanted surgically, providing a more permanent solution to the challenges faced by patients who have undergone mastectomy or lumpectomy procedures," she said.

Pezzano also believes better communication and collaboration between professionals working in science, engineering and design is needed to bring beneficial and innovative designs to public use.

"Communication and collaboration between different disciplines are essential to turn research and discoveries into practical applications that benefit society," she said.

"My aspiration is for my future practice to be an effective bridge between knowledge and needs and work on multidisciplinary projects to explore biomaterials, innovative technologies, and design facets."

Other prosthetic designs featured on Dezeen include a modular prosthetic leg that can be used in the shower and a prosthetic arm with self-learning technology, allowing it to predict intended movement faster than similar prosthetics.

The photography is by Tom Mannion unless stated.