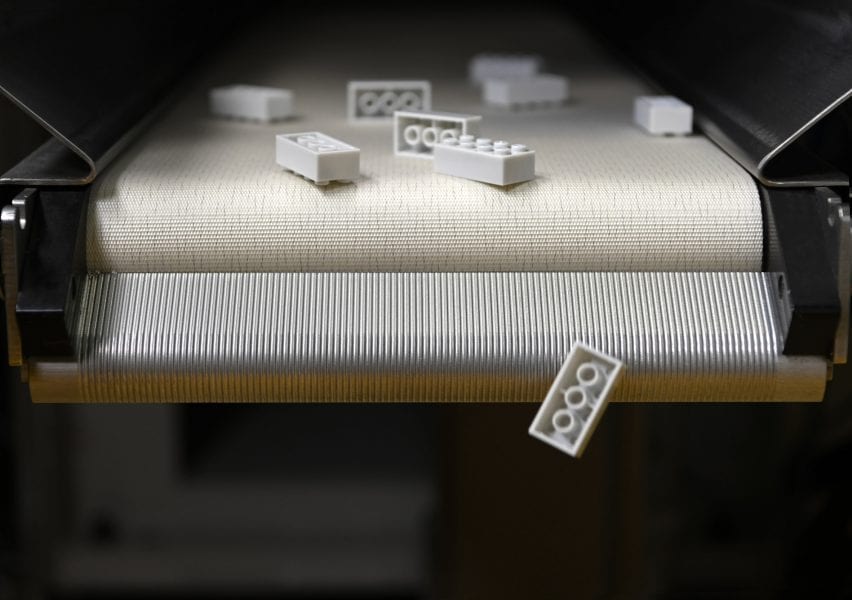

Lego ditches plans to make bricks from recycled plastic bottles

Danish toymaker Lego has abandoned its pilot programme to make recycled plastic bricks from discarded bottles after projections suggested that, adopted at scale, the material would ultimately have a higher carbon footprint.

The company introduced its first prototype bricks using recycled PET (rPET) in 2021 as part of the aim to have all of its products made from sustainable materials by the end of the decade.

But after two years of testing, Lego has now scrapped the project as calculations indicated that retooling its factories to process rPET – instead of the acrylonitrile butadiene styrene (ABS) used to form 80 per cent of its bricks – would ultimately generate more emissions over the product's lifecycle.

"It's like trying to make a bike out of wood rather than steel," Lego's head of sustainability Tom Brooks told the Financial Times, which broke the story.

"In order to scale production, the level of disruption to the manufacturing environment was such that we needed to change everything in our factories. After all that, the carbon footprint would have been higher. It was disappointing."

The rPET also requires large amounts of energy for processing and drying, Brooks explained, as well as additional chemicals so it can rival the durability of normal Lego blocks.

Instead of repurposing plastic bottles, Lego says it is now looking to find bio-based and recycled substitutes for the individual chemicals that make up ABS, as well as investigating alternative solutions.

"We remain fully committed to making Lego bricks from sustainable materials by 2032," a spokesperson for the company told Dezeen.

"We are currently testing and developing Lego bricks made from a range of alternative sustainable materials, including other recycled plastics and plastics made from alternative sources such as e-methanol."

The company is also exploring the potential of bioplastics, which has formed some of the flora found in Lego kits since 2018 as well as the company's recent Botanical Collection.

However, Lego CEO Niels Christiansen told the FT he believes no single material will be a silver bullet solution.

"We tested hundreds and hundreds of materials," he said. "It's just not been possible to find a material like that."

Instead, part of Lego's solution will be a focus on incremental emissions reductions as well as a takeback scheme, which the company is hoping to develop over the next few years so that unwanted bricks can be directly reused in new sets or recycled if they are no longer functional.

The news comes only a month after the company pledged to achieve net-zero emissions by 2050. Previously, Lego had only committed to a 37 per cent emissions reduction by 2032 compared to 2019.

All images are courtesy of Lego.