Shellworks turns discarded lobster shells into recyclable bioplastic objects

Four designers from the Royal College of Art and Imperial College have developed a series of machines that turn seafood waste into a biodegradable and recyclable bioplastic.

The project, called Shellworks, saw Ed Jones, Insiya Jafferjee, Amir Afshar and Andrew Edwards transform the shells of crustaceans into a paper-like material that could act as a sustainable alternative to single-use plastics.

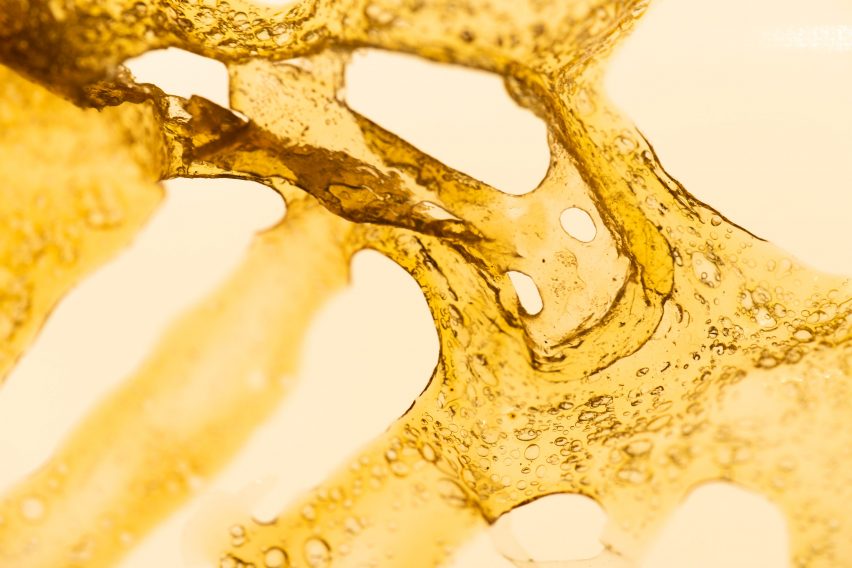

The material consists of a mixture of vinegar and a biopolymer called chitin – a fibrous substance that makes up the exoskeleton of crustaceans and the cell walls of fungi.

Despite being the world's second-most abundant biopolymer, chitin needs to be chemically extracted from its source before it can be turned into a practical material.

After realising how expensive chitosan – the commercial version of chitin – is to purchase, and how time-consuming the available extraction processes were, the designers decided to develop their own method.

"We spent weeks trying to extract even a handful of chitosan, which was when we realised we needed the right tools for the job," said the group.

They invented five manufacturing machines, called Shelly, Sheety, Vaccy, Dippy and Drippy, with which to transform the crustacean shells into different objects, being sure to not use any additives in the process that could affect the recyclability of the final product.

The first machine, called Shelly, is a small-scale extractor that enables the initial process of drawing out the chitin from the seafood waste.

"The extractor is designed to offer complete control over each parameter of the process in order to allow for further experimentation at the polymer level of the material," explained the designers.

Each of the other four machines exploit a specific property of the bioplastic solution to demonstrate its potential, resulting in different products such as anti-bacterial blister packaging, food-safe carrier bags and self-fertilising plant pots.

Sheety, for instance, is an evaporative sheet former that uses heat and wind to transform the bioplastic solution into flat sheets of material. These can then be glued together using the liquid form of the bioplastic.

Vaccy, on the other hand, is a steam-heated vacuum former. The bioplastic sheets can be formed into moulded packaging, taking on the shape of whatever object is put in the vacuum former.

The Dippy machine is a heated dip moulder comprising two solid metal elements attached to a heat source, which are dipped in the liquid material and left to dry, forming 3D vessels like cups and containers.

The versatility of the material also enabled the designers to achieve different material properties by adjusting the ratios of the base ingredients. This meant they could control the stiffness, flexibility and optical clarity of the material, as well as its thickness.

Once dried into one of its three different forms, the material can later be turned back into the original bioplastic solution, making it infinitely recyclable.

This can be done using the Drippy hydro-recycler machine, which drips a liquid solution of water and vinegar into a cup containing scraps of the dried bioplastic, gradually turning it back into its liquid form.

Alternatively, it can be poured onto soil in its liquid form as a natural, non-polluting fertiliser.

The group hope that by developing their own manufacturing methods that are tailored to how the material behaves, the bioplastic will be more easily accessible and therefore more widely adopted by other designers. This in turn will help to achieve a more circular economy.

"By designing scalable manufacturing processes, applications tailored to the material, and eco-positive waste streams, we believe we can demonstrate how chitosan bioplastic could become a viable alternative for many of the plastic products we use today," they said.

In a similar project, Chile-based designer Margarita Talep created a sustainable, biodegradable alternative to single-use packaging using raw material extracted from algae.