Tecla house 3D-printed from locally sourced clay

Bologna-based architecture studio Mario Cucinella Architects and 3D printing specialists WASP have collaborated to create a low-carbon housing prototype that is 3D printed using clay.

Named Tecla, a combination of the words technology and clay, the home was designed by Mario Cucinella Architects and was constructed and engineered by Wasp using clay sourced from a nearby riverbed.

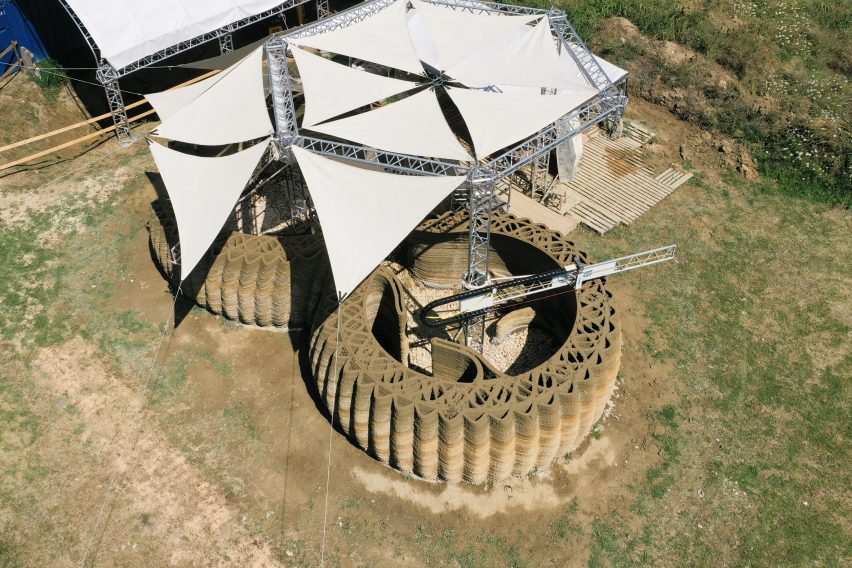

Printed in Massa Lombarda, Italy, the home is formed of two connected dome-shaped volumes with a ribbed outer wall that is made up of 350 stacked layers of 3D-printed clay.

The clay is arranged in undulating layers that not only provide structural stability but also to act as a thermal barrier.

The prototype was constructed using a multilevelled, modular 3D printer that uses two synchronised arms, each with a 50-square metre printing area that can print modules simultaneously.

By using this technology, housing modules can be built within 200 hours while consuming an average of six kilowatts of energy and reducing typical construction waste almost entirely said the construction team.

According to the studio, the housing prototype combines ancient building techniques with modern technology to form recyclable, low-carbon, climate-adaptable housing.

"TECLA responds to the increasingly serious climate emergency, to the need for sustainable homes and to the great global issue of the housing emergency that will have to be faced," said Mario Cucinella Architects.

"Particularly in the context of urgent crises generated, for example, by large migrations or natural disasters."

The 60-square-metre structure is 4.2 metres in height and comprises a living space, kitchen and sleeping area and is fitted with services and a circular skylight on its roof.

Although mainly windowless, its entrance is marked by a glazed door within a large lancet arch.

On its roof, large circular skylights were fitted within its narrowest point allowing light to enter the space throughout the day.

Its interior has a similar organic aesthetic as the walls were left bare with a lancet archconnecting the different zones.

Furnishings were also partly printed using locally sourced earth to unite the space and were designed to be reused or recycled to align with the circular values of the prototype.

The geometry of its envelope can be adapted and modified to work with different types of raw earth and respond to a variety of different climatic conditions.

"The aesthetics of this house are the result of a technical and material effort," said Cucinella. "It was not an aesthetic approach only. It is an honest form, a sincere form."

Tecla was developed as part of an eco-sustainability research study that looked to bioclimatic principles and vernacular architecture and construction to produce low-carbon homes.

"TECLA shows that a beautiful, healthy, and sustainable home can be built by a machine, giving the essential information to the local raw material," said Wasp founder, Massimo Moretti.

"We like to think that TECLA is the beginning of a new story," added Mario Cucinella Architects founder and creative director, Mario Cucinella.

"It would be truly extraordinary to shape the future by transforming this ancient material with the technologies we have available today."

In 2019, WASP used its Crane Wasp 3D printer to create a small home constructed using soil and agricultural waste.

Elsewhere, 3Strands and ICON collaborated to build four 3D-printed homes using disaster-proof concrete.

Photography is by Iago Corazza unless stated otherwise.