McLaren Production Centre by Foster + Partners

Architects Foster + Partners have completed a production centre for British sports car brand McLaren.

The facility has wide spans offering maximum assembly space while the basement is used for storage and machinery and a mezzanine offers a view of the production line.

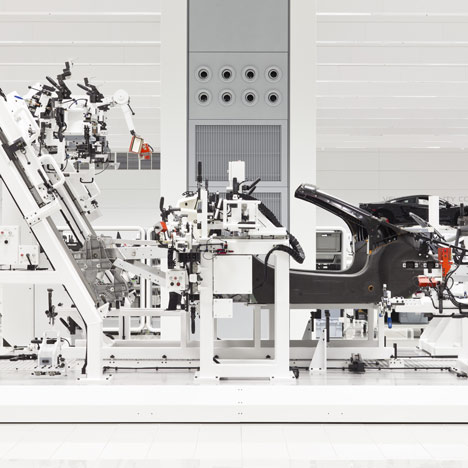

High-performance sports cars are manufactured, painted and tested on a linear production line that dictated the building's rectilinear form.

The McLaren Technology Centre's curved surfaces and horizontal aluminium cladding reference the existing buildings on the site in Woking near London.

An underground tunnel will link the production centre to the McLaren Technology Centre, which was also designed by Foster + Partners.

Trees screen the building from the nearby road and the whole structure is sunk into the incline of the site, reducing its visual impact on the landscape.

Foster + Partners recently completed another transport facility – the world's first commercial spaceport – and also unveiled a proposal for a massive transport hub in the Thames. See all of our previous stories on Foster + Partners.

All photography is from McLaren. The drawings below are from Foster + Partners.

Here's some more information from Foster + Partners:

The McLaren Production Centre is the second building designed by Foster + Partners at McLaren’s rural site on the outskirts of London. The 34,500-square-metre facility is intended for the manufacture of a range of high-performance road cars and is located to the south-west of the existing McLaren Technology Centre. The two buildings will be connected by a subterranean walkway, lined with interactive exhibition spaces. Sharing a common language of details and materials, the new building is clad in aluminium tubes, the rounded corners of its rectilinear plan reference the curves of the Technology Centre and the entrance, echoing the existing building, is a circular glass drum beneath the overhang of the roof canopy.

The state-of-the-art McLaren Production Centre is located to the south-west of the existing McLaren Technology Centre. The two buildings are connected by a subterranean walkway and share a common language of details and materials. The entrance, echoing the existing building, is a circular glass drum beneath the overhang of the roof canopy.

As a manufacturing facility, the building is inherently flexible, with a wide span between columns and fully integrated services. The linear arrangement of the two-storey structure mirrors the flow of the production line: components are delivered; the cars are assembled, painted and tested, and then pass through a rolling road and car wash, before leaving the building. Beneath this floor there is a full basement level for storage and plant and above is a mezzanine floor with views over the production line. Every stage of production takes place under the same roof. Initially it will take 10 days for an MP4-12C to be assembled; at peak production it will be possible to build one in five days, with a new car joining the line every 45 minutes.

Although the McLaren Production Centre represents a major increase in McLaren’s capabilities at its Woking campus, the building is dug into in the gentle incline of the site, to give it a discreet presence in the landscape. The lower floor is sunk completely below ground and the superstructure is almost invisible from the nearby road, with further screening provided by extensive tree planting.

The new McLaren Production Centre is designed to be environmentally efficient. The roof collects rainwater and has been designed to integrate photovoltaic panels in future; and the building incorporates a low-energy system of displacement ventilation. No soil was removed from the site, and all excavated material has been used to conceal the building within the green-belt landscape.

Lord Foster, Founder and Chairman, Foster + Partners: “The McLaren Production Centre is a further leap forward in the evolution of industrial buildings, both socially and in terms of working conditions and technologically in its flexibility and the sophistication of its services integration. The scale and grandeur of the main hall is a fitting complement to the purity of the McLaren cars, which will emerge from its production line. This project has been a wonderful opportunity to work once again with Ron Dennis, who is a great patron and friend. It is a testament to a fantastic team effort that this production centre was achieved in just twelve months.”

David Nelson, Head of Design at Foster + Partners, said: “It has been great to have the opportunity to build on the success of the Technology Centre by continuing our collaboration with McLaren, particularly our close working relationship with Ron Dennis. The project presented a unique set of challenges, from the constraints of the site to the operational demands of the different processes. McLaren’s work is incredibly precise – in many ways, the production line is like an operating theatre – the architecture reflects this with an industrial building of the highest quality in every detail. As well as drawing on the understanding we gained with the Technology Centre, the Production Centre echoes its minimal aesthetic – visually, they can be seen as a family of buildings, unified by a common language of finishes and a consistent materials palette.”

Nigel Dancey, a design director at Foster + Partners, said: “It is a privilege to design two companion buildings for the same client and it has been a great experience. While the McLaren Technology Centre took six years to design and build, the fast- track programme meant that the McLaren Production Centre was completed in a third of the time. The same team has worked on both buildings and this continuity has helped to make this ambitious timescale possible. We were also able to draw on the wider capabilities of our studio: the McLaren Production Centre is a great example of integrated design, with services built into the structure to create a highly flexible space.”

Click above for larger image

Iwan Jones, a partner at Foster + Partners, said: “Our intention was to design a new kind of industrial building, which would be an elegant addition to the McLaren Technology Centre. The two buildings are physically connected by a 100-metre- long tunnel and unified by a common architectural language – we established a ‘kit-of-parts’ system for the project, a family of finishes and details. By optimising structural spans to allow a largely clear floor space, we have essentially created a big empty box, with services integrated within the structural zones, wall and floor voids.

Click above for larger image

This flexible form ensures that the building is also highly cost efficient – it will support McLaren’s production needs today and in the future. And the experience of the finished McLaren Production Centre is equally impressive. You don't realise its scale until you are actually inside the assembly hall, where visitors will have a fantastic view of the different processes from the viewing gallery.”