Ganni unveils handbag made from bacterial leather at LDF

Bacteria were used to grow this one-off edition of the Bou Bag by Danish fashion brand Ganni, made from a leather alternative by London biotech company Modern Synthesis that contains no plastic or petrochemicals.

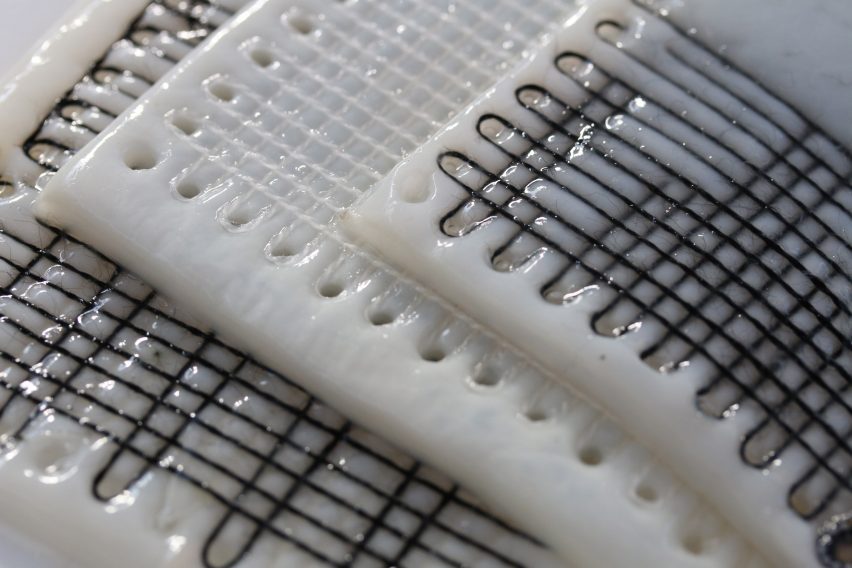

On show as part of the Material Matters fair at London Design Festival, the handbag was made by cultivating nanocellulose – a fibre produced by certain bacteria – over a framework of threads.

The result is a textile that drapes much like cowhide but could generate up to 65 times less greenhouse gas emissions than real leather, Modern Synthesis claims.

Crucially, the material does not rely on any plastic coating for durability, unlike the bacterial nanocellulose jacket that Ganni debuted at the Global Fashion Summit in July. However, the bag still has a lining that contains plastic microfibre.

The two companies are now striving to make the handbag commercially available by early 2025.

"Collaborating with Ganni on the Bou Bag has allowed us to showcase the viability of bacterial cellulose-based materials in real-world applications," said Modern Synthesis CEO Jen Keane.

"These one-off showcase pieces are pivotal in evaluating a material's workability and appeal to both designers and consumers – which paves the way for its eventual integration into everyday fashion."

Based on a process developed by Keane during her graduate degree at Central Saint Martins, the material's production involves growing bacteria on a supportive scaffold of threads and feeding it with agricultural waste.

The microbes then convert the sugar found in the food scraps into nanocellulose – a finer form of the cellulose fibres found in cotton and linen that is around eight times as strong as stainless steel relative to its weight.

Based on the type of thread used to form the framework, the resulting material can either biodegrade at the end of its life or can be recycled like other cellulose-based textiles.

Modern Synthesis, which was founded by Keane together with synthetic biologist Dr Ben Reeve, raised $4.1 million (£3.3m) in seed funding last year to help scale up its production, although true commercial scale is still some ways off.

"Our top priority is to uphold the quality that brands like Ganni expect, at the same time as making sure it’s done in a sustainable way," Keane told Dezeen.

"We are also actively working to scale up our own material production capacities so that these lower-impact textiles are more readily accessible for commercial scale as currently, we're only able to produce limited quantities," she added.

The company is now working with Ganni to find alternatives for the plastic microfibre lining used in the design, with the aim of creating a 100 per cent cellulose-based version of the Bou Bag.

Bacterial nanocellulose is one of a number of material innovations – including Mylo mycelium leather and Pyratex's banana-waste fabric Element 2 – that Ganni has invested in as part of its Fabrics of the Future initiative.

The company is committed to phasing out all virgin leather from its products by the end of this year.

Material Matters is on show as part of London Design Festival 2023 from 20 to 23 September 2023. See our London Design Festival 2023 guide on Dezeen Events Guide for information about the many other exhibitions, installations and talks taking place throughout the week.