The Sugar Lab by Kyle and Liz von Hasseln

Los Angeles architects Kyle and Liz von Hasseln have set up a business that produces 3D-printed sugar sculptures for wedding cakes, table centrepieces and pie toppings.

The duo founded 3D printing company The Sugar Lab while studying at the Southern California Institute of Architecture (SCI-Arc), where they graduated last autumn.

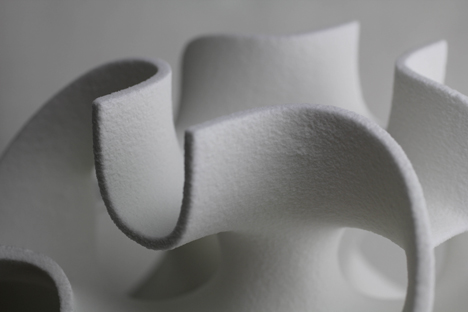

Their sugar sculptures are made using a process similar to standard 3D printing: a mixture of alcohol and water is applied selectively in layers to wet and then harden the sugar.

"If you've ever made frosting and left the mixing bowl in the sink overnight, you know that moistened sugar gets quite hard," said the designers. "That's the underlying concept of 3D printing with sugar."

The resulting pieces taste like normal sugar, but could be flavoured. The pair are working on a range of custom projects including cake toppers, centrepieces, pie-crust lattices and a four-tiered wedding cake with a 3D-printed sugar stand.

"That's an exciting part of 3D printing sugar for us - transforming sugar into a structural, sculptural medium that can start to define the form of the food instead of the other way around, and even to support it structurally," the designers added.

"We see 3D-printed sugar as the best place to start, in terms of 3D printing food," they continued. "There’s an existing cultural ritual of desert and celebration that embraces experimentation and embellishment. It’s primed to embrace technology like 3D printing as a design tool, and we’re just tapping into that."

Other sugar design projects on Dezeen include a patterned dance floor of sieved icing sugar, a machine for automatically decorating cakes and jewellery grown on threads suspended in sugar solution.

Other unusual food we've featured recently includes bio-engineered dishes that wriggle around on the plate, yoghurts, ice creams and cheeses with edible packaging and fruit labelled with laser tattoos instead of stickers.

We've also featured 3D-printed models of cereal, pasta and hamburgers, and you can read more about when we can expect to tuck into 3D-printed steaks in an extract from Print Shift, our one-off print-on-demand magazine all about additive manufacturing.

See more stories about food design »

See more stories about 3D printing »

Update: The Sugar Lab was acquired by 3D printing giant 3D Systems in SEptember 2013 and launched the first 3D printer certified for food use at the Consumer Electronics show in January 2014.

Here's some more information from The Sugar Lab:

What we do

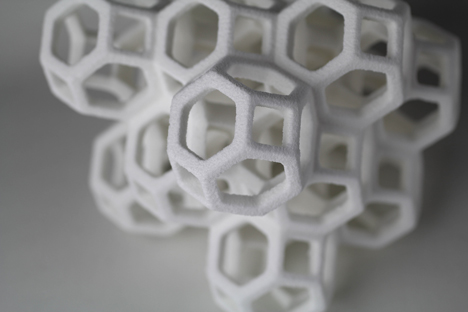

The Sugar Lab is a micro-design firm for custom 3D printed sugar. With our background in architecture and our penchant for complex geometry, we're bringing 3D printing technology to the genre of mega-cool cakes. 3D printing represents a paradigm shift for confections, transforming sugar into an dimensional, structural medium. It makes it possible to design, digitally model and print an utterly original sugar sculpture on top of a cake.

All of our projects are custom. The design process begins from scratch, when we hear from you. Tell us your idea/theme/vibe. Give us a swatch of lace from your gown/a polaroid of the wrought iron gate at your venue/a postcard of your hometown skyline. Or just come to The Sugar Lab and brainstorm with us. It doesn't even have to be a cake; centerpieces, chandeliers, cupcake toppers, sugar cubes, pie-crust-lattice, grapefruit sweeteners, all possible and possibly awesome.

How we got started We're Kyle and Liz von Hasseln, a husband and wife architectural design team in Los Angeles. The Sugar Lab started about two years ago, when we were graduate students in architecture. We were living in a tiny apartment in Echo Park with a correspondingly tiny outdoor kitchen. We didn't have an oven, and when we realized that meant we couldn't bake our friend Chelsea a cake for her birthday, we decided to try to 3D print one, instead.

After a period of trial and error (during which her actual birthday came and went!) we managed to print a simple cupcake topper that spelled out 'Chelsea' in cursive sugar. Chelsea loved it! We thought other people might like 3D printed sugar, too, so when we graduated last fall, we spent the time to really optimize our process, and we started The Sugar Lab--officially--in our new studio here in Silver Lake.

Our process

After some brainstorming and messy hand sketching, we work to translate our ideas into 3D digital models. Our backgrounds in architecture serve us well during the modeling process, which has a lot to do with structural and material considerations as well as making design moves. We're always aiming for a sculptural, dimensional form that maximizes what 3D printing brings to sugar.

As for the actual printing process, if you've ever made frosting and left the mixing bowl in the sink overnight, you know that moistened sugar gets quite hard. That's the underlying concept of 3D printing with sugar. We use a mixture of water and alcohol, applied very precisely in a layer-wise manner, to selectively wet and harden the sugar substrate. The process is fundamentally similar to other 3D printing applications, we've just optimized the process for resolution and strength with sugar, rather than with a standard 3D printing material.

What's so cool about 3d=printed sugar?

3D printing transforms sugar into a structural, sculptural element that can interact with food on different terms. 3D printed sugar can be used to sweeten or to ornament, but it can also start to define the form of the food instead of the other way around, or even to support it structurally. For example, we're very excited to be working right now with some seriously talented cake artists at a well-known bakery in Hollywood to design a four-tiered wedding cake with a 3D printed sugar cake-stand, and 3D printed sugar-tiers supporting traditional cake tiers. What's exciting for us is, in terms of the possibilities of 3D printed sugar, is how differently everyone thinks about how to use it. People are constantly suggesting things we've never thought of, and it's very fun to try to implement those ideas.