"You can design anything and have it 3D-printed"

Bart Veldhuizen, community manager at online 3D-printing service Shapeways, takes Dezeen on an exclusive behind-the-scenes tour of the company's Eindhoven print facility for the final instalment in our series of movies about additive manufacturing.

Shapeways is a website where customers can upload a 3D model and get it printed out and shipped to their front door. It also provides an online marketplace where designers can sell their 3D-printed designs, which Shapeways prints out and delivers to order.

Veldhuizen gave us a tour of the company's European headquarters in Eindhoven as part of our research for Print Shift, the magazine about 3D printing we launched earlier this year.

"Shapeways is the world's leading 3D printing marketplace and community," he says in the movie. "You can design anything, have it 3D-printed, share it, sell it, make it your business. We have 250,000 community members right now who are designing their own work and who are selling and buying on the website."

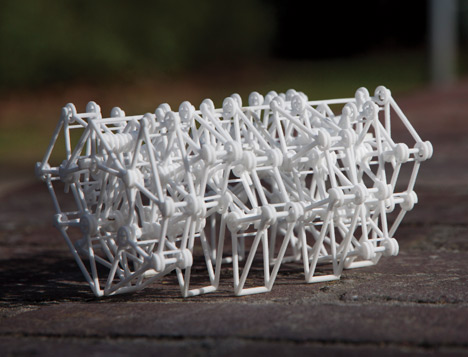

One of the most popular products available on the website is a fully working model of a walking sculpture created by artist Theo Jansen, Veldhuizen says. Called Strandbeest, the intricate toy is printed in one go, without any assembly required. An optional propellor can also be printed separately and added to the model to make it wind-powered.

"It contains 75 moving parts and it will actually walk," says Veldhuizen. "It's wind-powered, you blow on the propeller and off it goes."

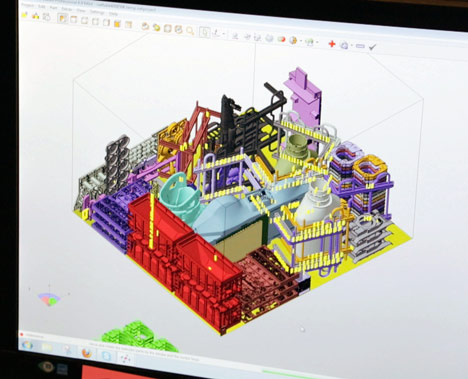

Starting the tour, Veldhuizen takes us to a computer room, where incoming 3D files are processed and assessed.

"After you place an order, we need to check if a part is actually printable or not," Veldhuizen explains. "That can mean several things. Will it survive the printing process? Will it survive shipping? All kinds of factors like that."

Shapeways do not print out objects one at a time, as you might using a desktop 3D printer. Rather, multiple 3D objects are printed together in large trays.

"We try to plan our printers as efficiently as possible," says Veldhuizen. "Sometimes we fit in 300 to 400 parts in one printer. The more we can fit in, the more efficiently we can produce, of course."

Veldhuizen then takes us to one of the company's printing rooms, where laser sintering machines print models out of white nylon powder.

"We deposit a fine layer of powder on the print bed, a laser sinters one cross-section at a time and then the process repeats," explains Veldhuizen. "After the printing is done, we unpack the tray. We take the entire printed tray, we push it out of the box and we take it apart by hand."

He continues: "Once the printer starts, it prints about one centimetre an hour. A medium-sized tray can take 24-36 hours to print. After that it's still quite hot and will take the same amount of time to cool down. Only after that we can start unpacking it."

For an extra cost, Shapeways can also polish and dye the 3D-printed models.

"For most of the materials that we use, we look to see how we can make it more interesting for designers or consumers," says Veldhuizen. "In the case of nylon prints, we found that polishing it after printing will give a much more smooth feeling, much closer to injection-moulded plastic."

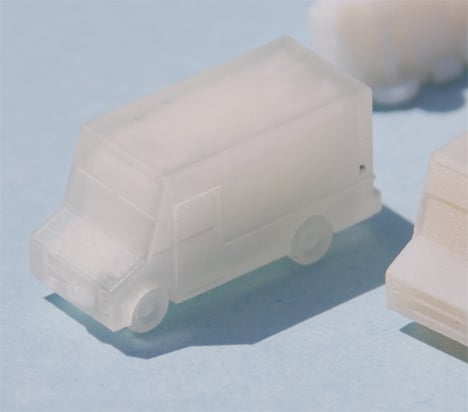

Next, Veldhuizen takes us to a different print room, which produces what Shapeways calls "frosted ultra-detail" models. Here, multi-jet modelling machines print out highly detailed models by depositing fine layers of plastic resin, which are cured with a UV light.

"Ultra detail is a material that's very highly detailed; we can print walls up to 0.1 millimetres thick," says Veldhuizen. "It's not powder-based, it's a photo-acrylic and then we use a UV light to cure it. This is mainly used by designers who want to create miniature trains or miniature game models."

We finish the tour at Shapeways' distribution centre, where the 3D-printed models are given a final quality control inspection before being shipped out to customers.

"After ordering, it takes between 2-3 weeks for an order to arrive at your home," says Veldhuizen. "After printing, we check every part to make sure it's printed to the right quality standards and if it passes it gets shipped out."

See all our stories about 3D printing »

Find more information about Print Shift and see additional content here.