Genetic Stair by Caliper Studio

Brooklyn office Caliper Studio have completed an apartment in New York that features a very complicated stainless steel staircase.

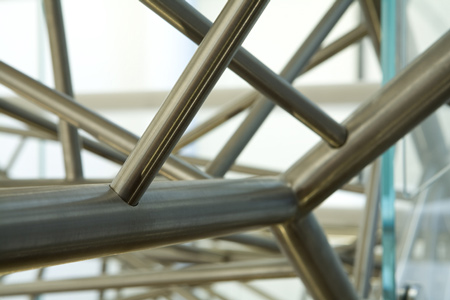

Called Genetic Stair, the fifteen-foot staircase has Corian treads supported by a structure of diagonal rods.

The project was designed for two art collectors and involved combining two existing apartments to form a combined living and gallery space.

Materials include stainless steel, translucent Corian, blackened steel and walnut wood.

Mobile translucent partitions can be positioned within the apartment to divide it further.

Photographs are by Ty Cole.

The text below is from Caliper Studio:

This project is Caliper Studio’s newly completed home for two art collectors on New York’s Upper West Side.

Located in the top two floors of a Mckim Mead and White building, the design merges two apartments to create a spacious domestic art gallery where home and art are intertwined.

The spaces are strung in an open sequence around a library core, from the entrance to the kitchen with a free standing stair and living spaces in between.

Continuous long walls enclose the space to display works from the owners' collection: Tomma Abts, Lawrence Weiner, Franz Ackermann and more.

Full-height, translucent moveable partitions can be positioned to provide private enclosures when needed without reducing the overall scale of the space.

The stair codenamed “Genetic Stair” was conceived as a jewel in the apartment. It is placed just to the side of the entrance and is inserted in a newly formed floor opening.

Above, to one side of the opening, a full height glass wall brushes light deep into the space below.

Supported only at the top and bottom, the stair turns two hundred seventy degrees and rises fifteen feet.

The supporting structure is a modified space frame, in which the distribution of the diagonal rod members was determined using custom designed computational algorithms to arrive at a structurally sound solution.

The stair was fabricated by our metal fabrication shop. The complete computer model was used to seamlessly transition to the shop floor.

It provided the precise 3D files to laser cut the holes in the stainless tubes and enabled the development of sophisticated jigs/templates to layout the various assemblies.

A material palette of stainless steel, translucent white Corian, blackened steel and walnut was selected and forms a quiet but sharp backdrop for the art.

Precisely crafted details are expressed most noticeably in the stair’s diagonal connections, the door frames and countertops.

Each is transformed into an opportunity to express the material’s capabilities and the beauty of carefully crafted detail assemblies.